Method for treating waste cathode ray tube (CRT) cone glass by strengthening acid leaching through mechanical activation technology

A technology of mechanical activation and acid leaching treatment, applied in the direction of silicon oxide, silicon dioxide, process efficiency improvement, etc., can solve the problems of high back-end treatment costs, high energy consumption, large amount of waste residue, etc., and achieve easy large-scale industrialization The effect of mature production and process technology and high activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

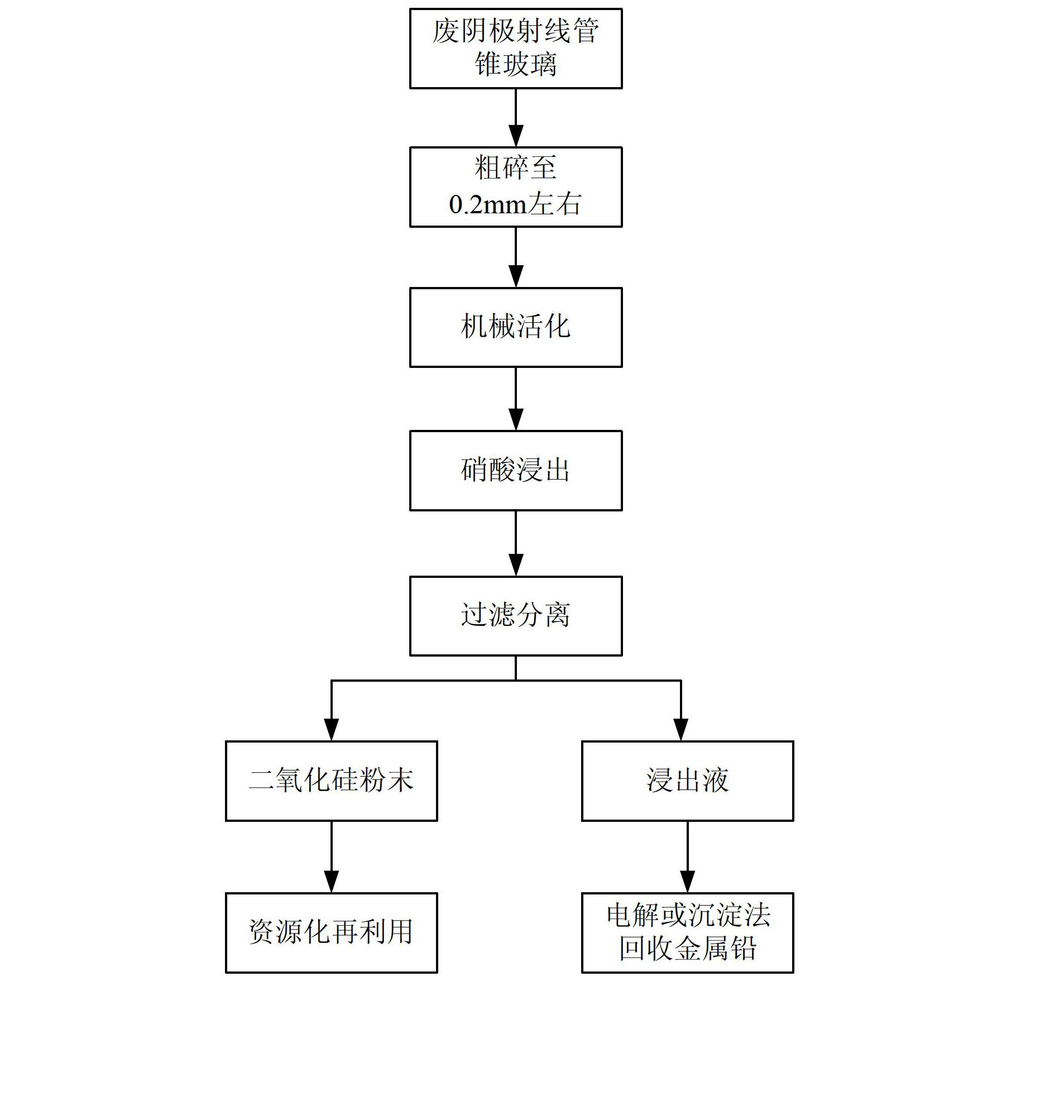

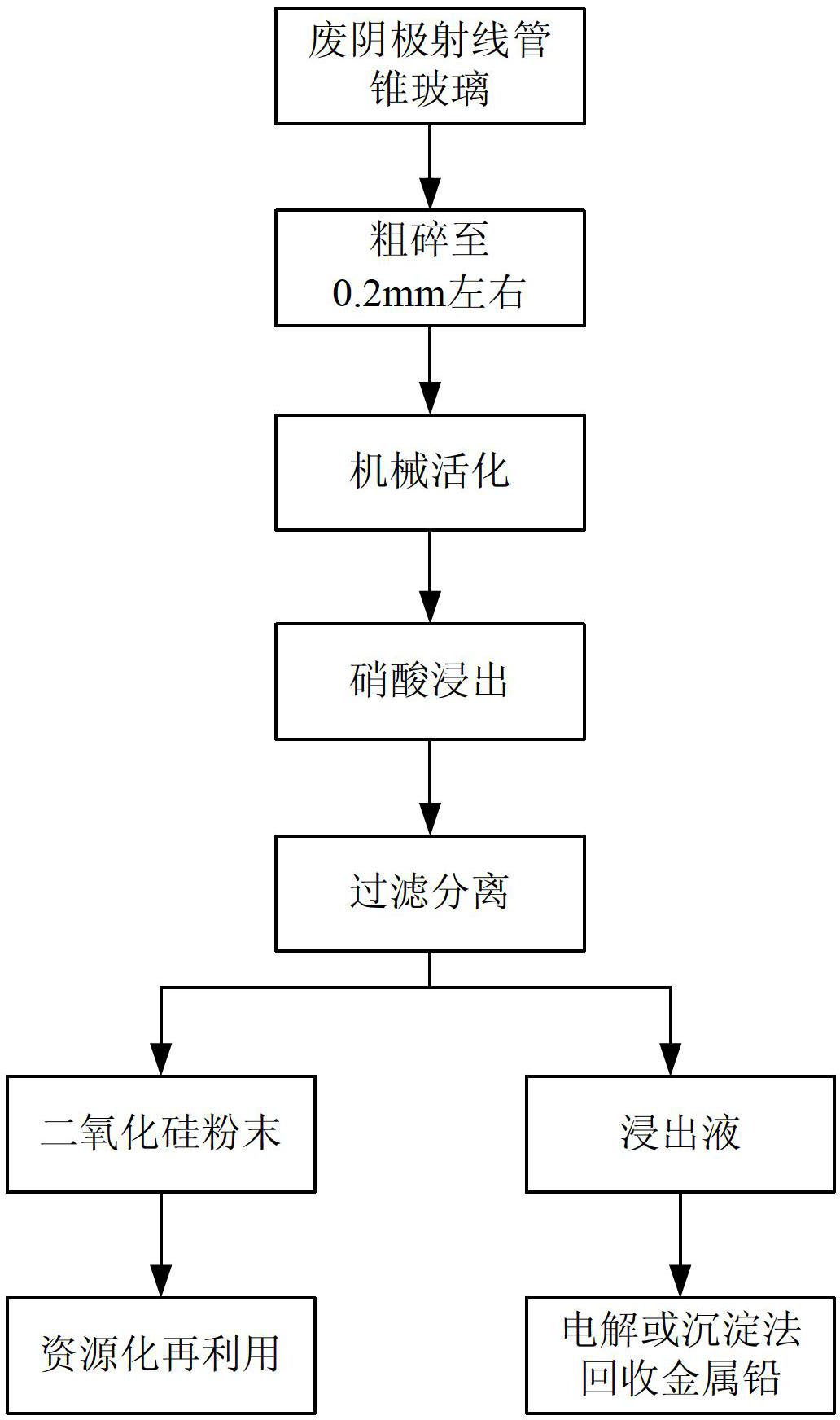

Method used

Image

Examples

Embodiment 1

[0020] First, the cone glass separated by the CRT cone screen is roughly crushed to obtain cone glass particles with a particle size of about 0.1mm;

[0021] Get 4g of waste cathode ray tube cone glass after coarse crushing and join in the ball milling jar of planetary high-energy ball mill, the filling ratio of ball milling medium (zirconia) and CRT cone glass particles is 20:1, the mechanical ball milling speed is 300rpm, and the activation time is 30min to obtain mechanical Activated CRT cone glass powder.

[0022] Place the mechanically activated CRT cone glass powder sample in a 70°C, 3.0mol / L nitric acid solution with a liquid-solid ratio of 25:1mL / g, and mechanically stir for 120min. After the above-mentioned leaching reaction is completed, filter while hot to realize solid-liquid separation of the mixed liquid.

[0023] The recovery rate of metallic lead in the CRT cone glass was 19.7% after analysis.

Embodiment 2

[0025] First, the cone glass separated by the CRT cone screen is roughly crushed to obtain cone glass particles with a particle size of about 0.2mm;

[0026] Get 4g of waste cathode ray tube cone glass after coarse crushing and join in the ball milling jar of planetary high-energy ball mill, the filling ratio of ball milling medium (zirconia) and CRT cone glass particles is 20:1, the mechanical ball milling speed is 400rpm, and the activation time is 60min to obtain mechanical Activated CRT cone glass powder.

[0027] Place the mechanically activated CRT funnel glass powder sample in 90°C, 2.0mol / L nitric acid solution with a liquid-solid ratio of 25:1mL / g, and react with mechanical stirring for 30min. After the above-mentioned leaching reaction is completed, filter while hot to realize solid-liquid separation of the mixed liquid.

[0028] The recovery rate of metallic lead in the CRT cone glass was 61.9% after analysis.

Embodiment 3

[0030] First, the cone glass separated by the CRT cone screen is roughly crushed to obtain cone glass particles with a particle size of about 0.5mm;

[0031] Get 4g of waste cathode ray tube cone glass after coarse crushing and join in the ball milling tank of planetary high-energy ball mill, the filling ratio of ball milling medium (zirconia) and CRT cone glass particles is 20:1, the mechanical ball milling speed is 500rpm, and the activation time is 120min to obtain mechanical Activated CRT cone glass powder.

[0032] The mechanically activated CRT cone glass powder sample was placed in 95°C, 1.0mol / L nitric acid solution, the liquid-solid ratio was 150:1mL / g, and the reaction was mechanically stirred for 60min. After the above-mentioned leaching reaction is completed, filter while hot to realize solid-liquid separation of the mixed liquid.

[0033] The recovery rate of metal lead in the CRT cone glass was 92.5% after analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com