Method for catalytically degrading chlorobenzene by double-stage discharge plasma and preparation method of used catalyst

A discharge plasma and catalytic degradation technology, applied in the field of chlorobenzene degradation, can solve problems such as incomplete decomposition of chlorobenzene, and achieve the effects of thorough purification, high catalytic activity and rapid chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

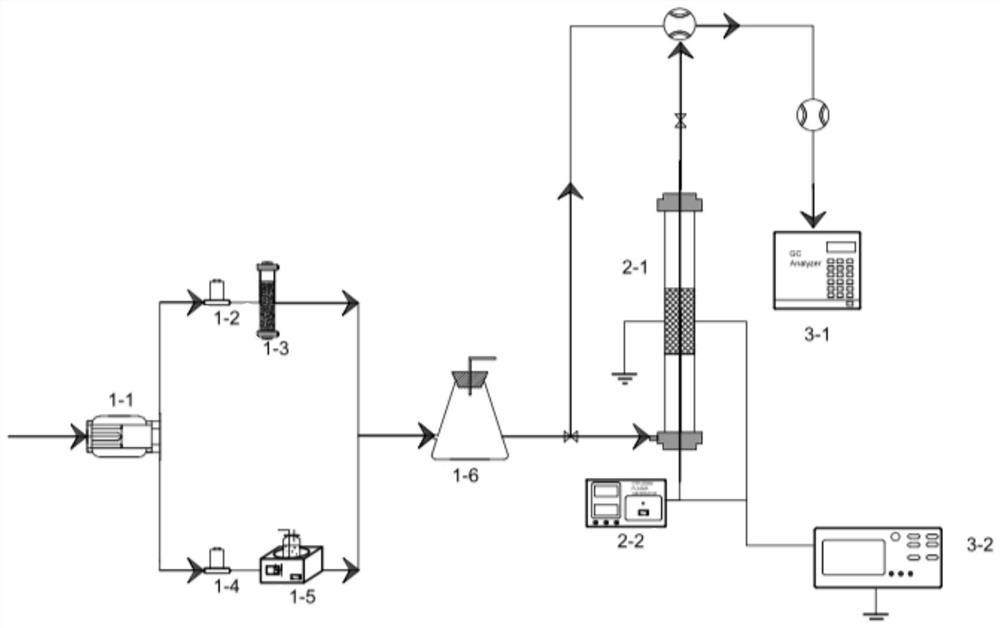

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of Co-Mn / TiO 2 Catalyst: Dissolve 0.29 g of manganese nitrate and 0.29 g of cobalt acetate in 50 mL of distilled water and stir to form a homogeneous solution, slowly mix 2 g of TiO 2 Add the powder to the above solution, and stir at 35~40°C for 2 h, slowly add 25 mL Na 2 CO 3 solution (0.2 mol / L), the precipitate was stirred for 4 h, then filtered and washed with deionized water until neutral, dried overnight at 80 °C, and calcined at 350 °C (3 °C / min) for 5 h in a muffle furnace. Get Co-Mn / TiO 2 catalyst. The resulting Co-Mn / TiO 2 The SEM and TEM images of the catalyst are as Image 6 As shown, the XRD pattern is as Figure 7 As can be seen from the figure, Co-Mn / TiO 2 The specific surface of the catalyst is 51.03 m 2 / g, the metal oxide is evenly distributed on TiO 2 surface.

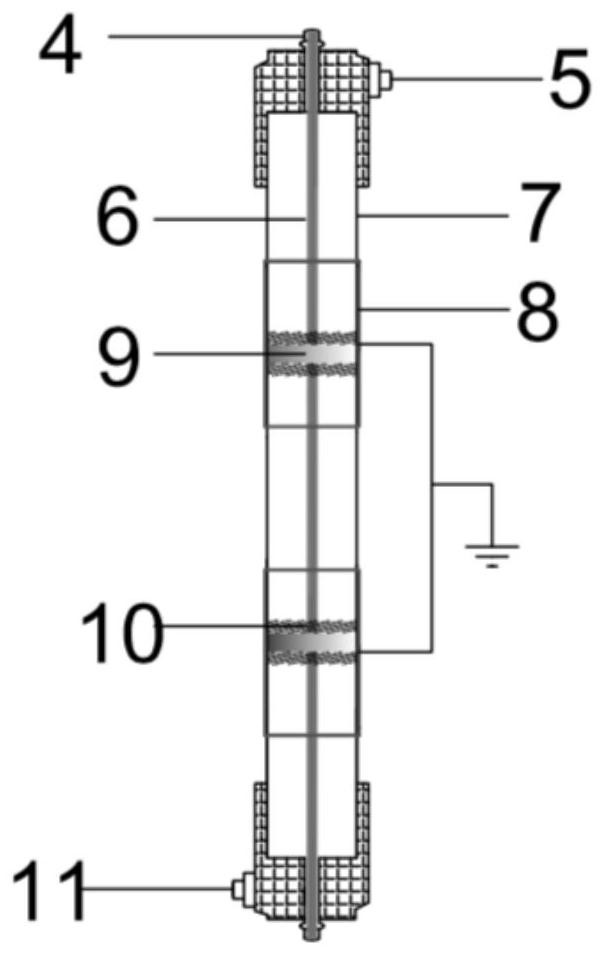

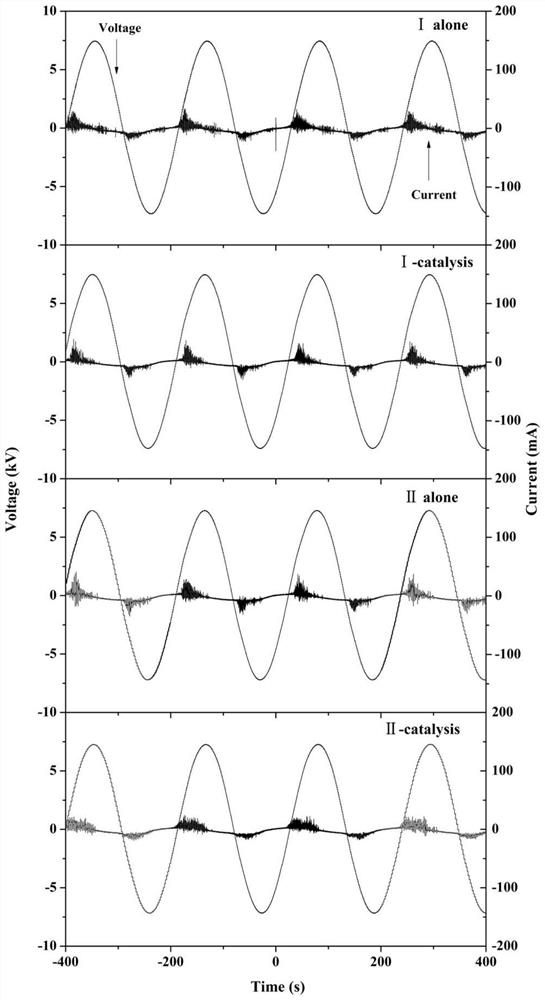

[0033] (2) Catalytic degradation of chlorobenzene: the distance between the discharge intervals of the double-stage discharge plasma is 1 cm, the length of each disc...

Embodiment 2

[0035] The difference from Example 1 is that the peak voltage of the plasma is 14 kV.

Embodiment 3

[0037] The difference from Example 1 is that the peak voltage of the plasma is 16 kV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com