Preparation method and application of polyacid-based metal organic framework nanocrystalline catalyst

An organic framework and catalyst technology, which is applied in the field of preparation of polyacid-based metal-organic framework nanocrystalline catalysts, to achieve good catalytic activity, uniform size, and mild catalytic reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

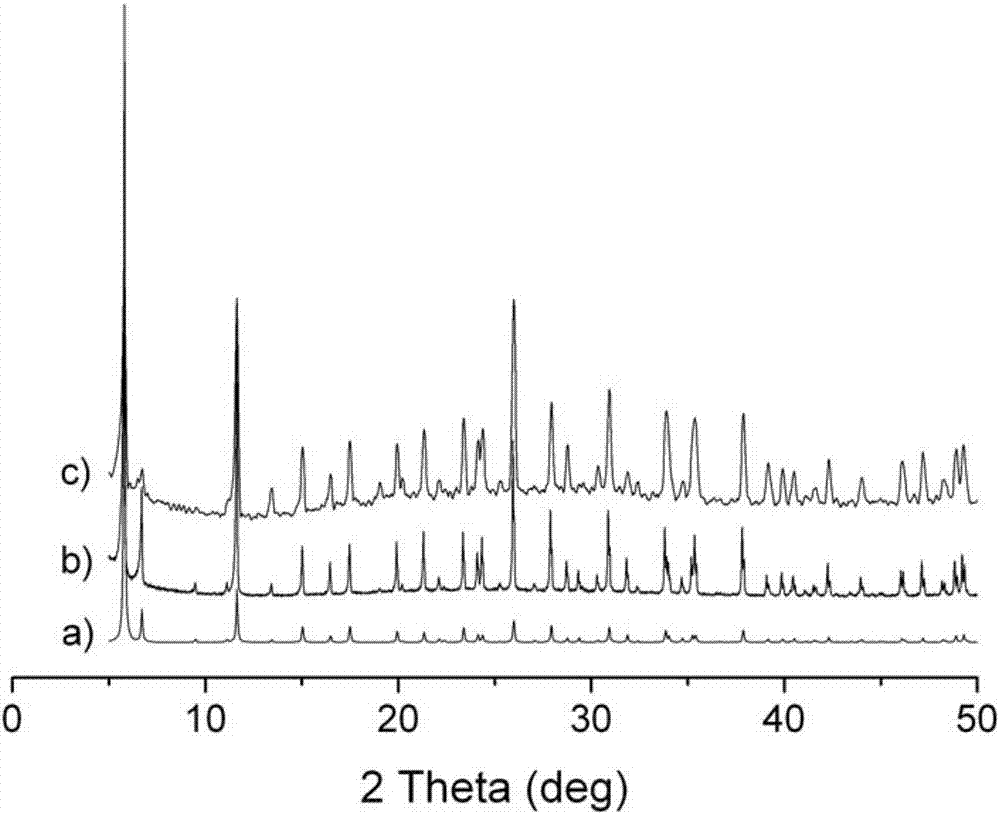

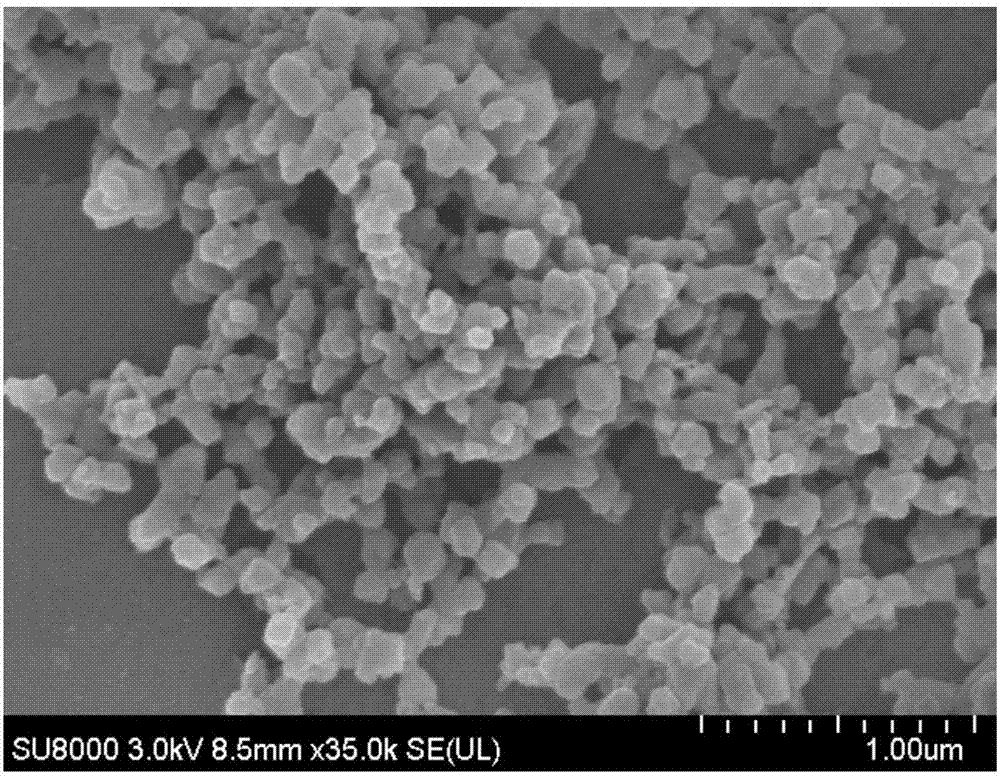

[0022] Specific embodiment 1: Cu 12 (TMA) 8 h 3 PW 12 o 40 liquid assisted milling synthesis

[0023] Take 0.24g Cu(NO 3 ) 2 ·3H 2 O and 0.28g H 3 PW 12 o 40 Dissolve in 10 mL of deionized water, adjust the pH value of the solution to 4 with NaOH, and dry the solution to obtain the mixture powder. The obtained powder and 0.14 g of trimesic acid were mixed in an agate mortar, and 1 mL of methanol was added for grinding. The mixed powder gradually turned blue. The blue powder was washed twice with water and twice with ethanol, and then dried in an oven at 60° C. for 24 hours after centrifugation to obtain a polyacid-based metal-organic framework nanocrystal catalyst. Specific embodiment 2: Cu 12 (TMA) 8 h 3 PW 12 o 40 Application of Catalytic Phenol Degradation

specific Embodiment 2

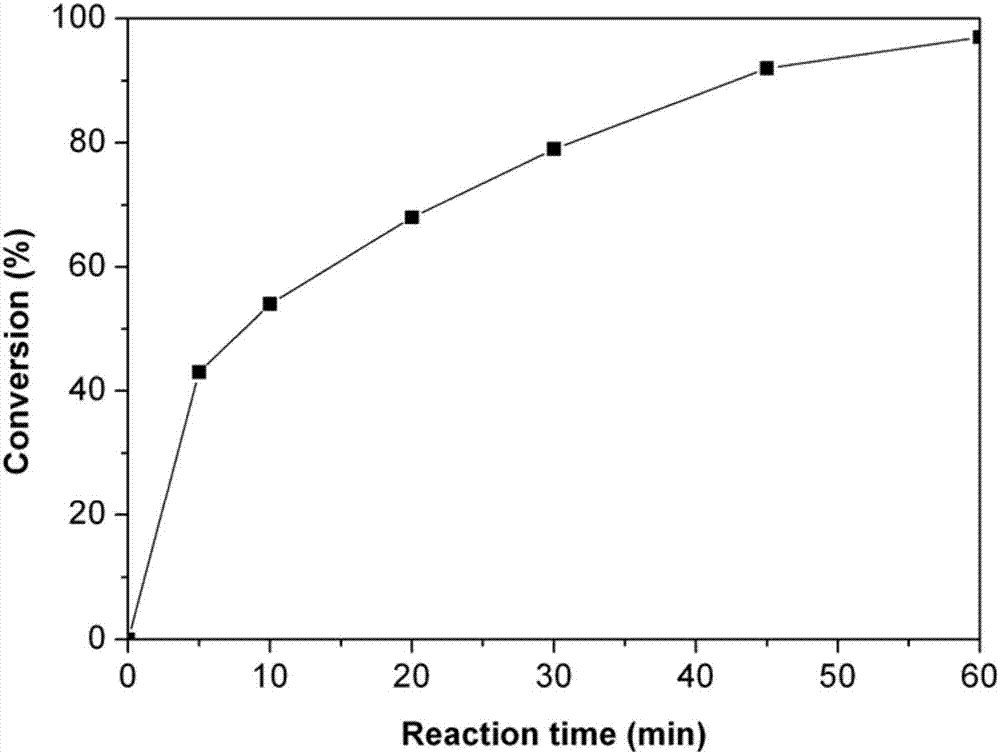

[0024] Dissolve 10 mg of phenol in 50 mL of deionized water to prepare a phenol aqueous solution with a concentration of 200 mg / L. Then, 0.05 mmol of catalyst and 15 mL of hydrogen peroxide (30 wt %) were added to the aqueous phenol solution, and the reaction temperature was 40° C. After reacting for 1 hour, monitored by gas chromatography, the conversion rate of phenol had reached 97%, and TOC detection showed that the mineralization rate had reached 87%. The conversion rate of the above reaction is monitored by gas chromatography, and the mineralization rate is monitored by TOC analyzer. The relationship of phenol conversion rate with time is shown in the appendix image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com