Treating method and electric flocculation device for Cu-EDTA complex wastewater

A treatment method and electro-flocculation technology, applied in the environmental field, can solve the problems of unsatisfactory treatment effect of Cu-EDTA complex wastewater, and achieve the effects of high degree of automation, high mineralization rate and environmental protection cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

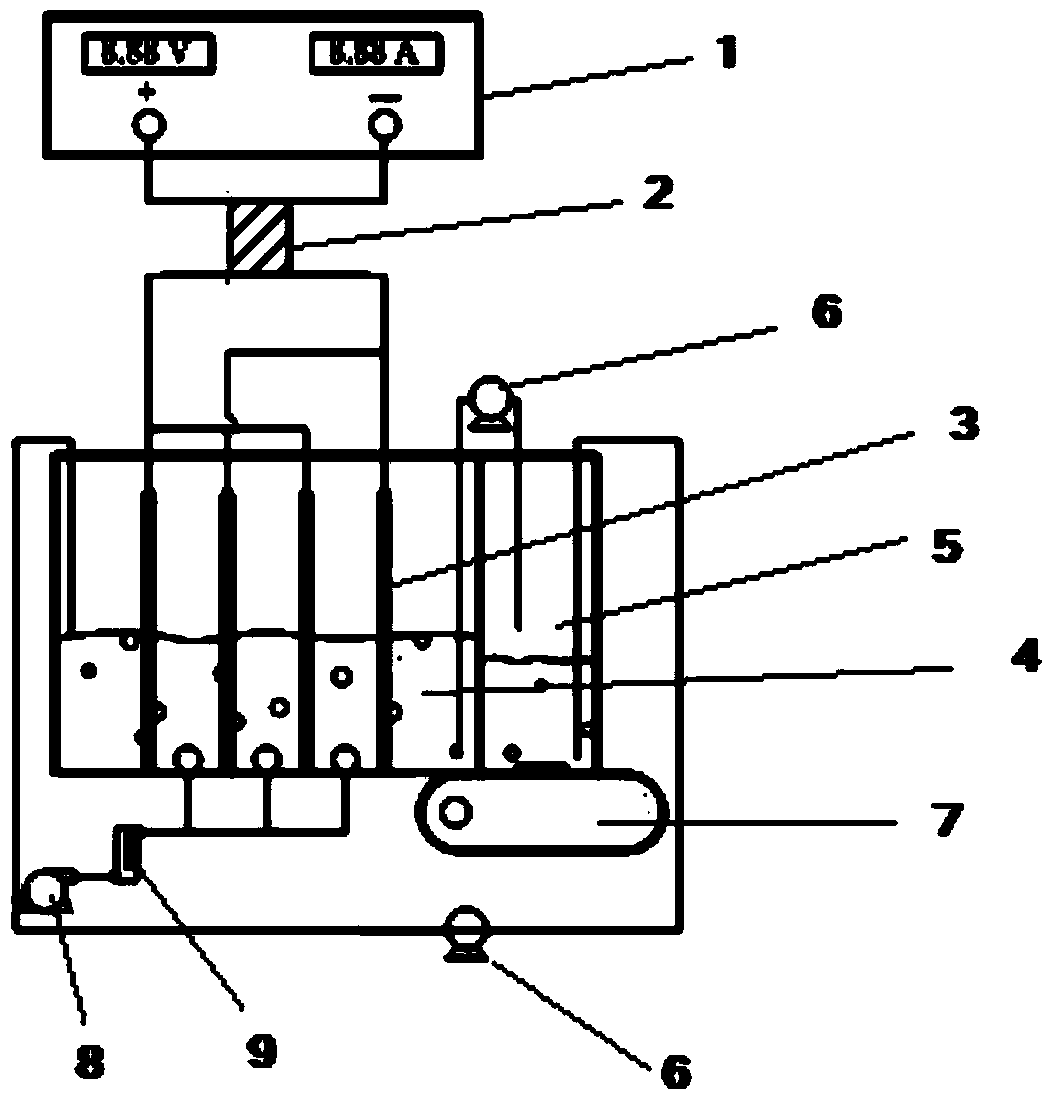

[0061] see figure 1 : An electroflocculation device includes a power supply 1, a relay 2, an electrode 3, a reaction tank 4, a mixing tank 5, a peristaltic pump 6, and an air pump 8. One end of the electrode 3 is connected to the power supply 1 through the relay 2, and the other end of the electrode 3 Set in the reaction tank 4, the mixing tank 5 is arranged side by side on the side of the reaction tank 4. The reaction tank 4 and the mixing tank 5 are filled with Cu-EDTA complex wastewater, and the exchange of the Cu-EDTA complex wastewater between the reaction tank 4 and the mixing tank 5 is realized through the peristaltic pump 6 . Preferably, the bottom of the mixing tank 5 is provided with a magnetic stirrer 7 to realize rapid mixing of Cu-EDTA complex wastewater.

[0062] The air pump 8 is arranged outside the reaction tank 4, and air is passed into the bottom of the reaction tank 4 through the air pipe. Preferably, a flow meter 9 for detecting air flow is provided betw...

Embodiment 2

[0068] A method for treating Cu-EDTA complex wastewater by using an aluminum-iron electrode combined with electrocoagulation:

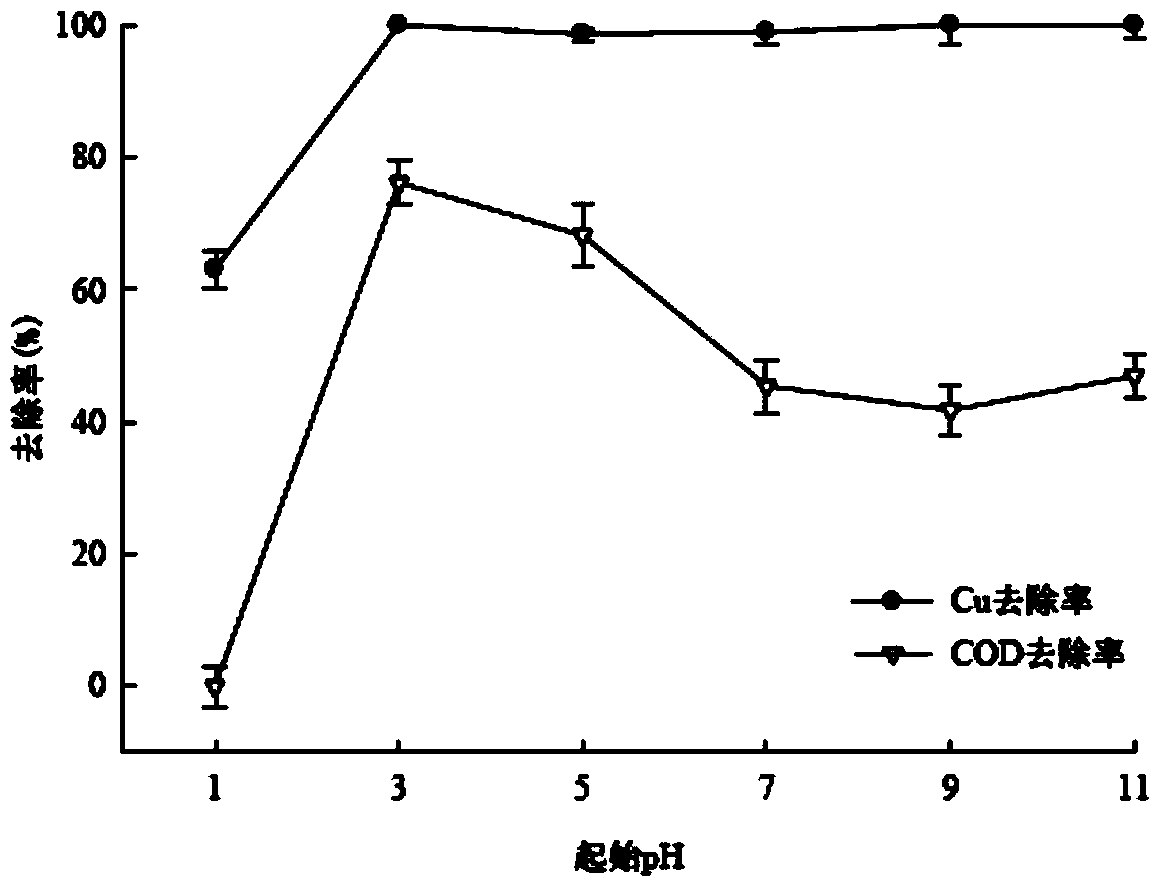

[0069] 1) Cu-EDTA complex wastewater, wherein the copper ion content is 50mg / L, the COD concentration content is 200mg / L, and the pH value is adjusted to 3.01 with hydrochloric acid;

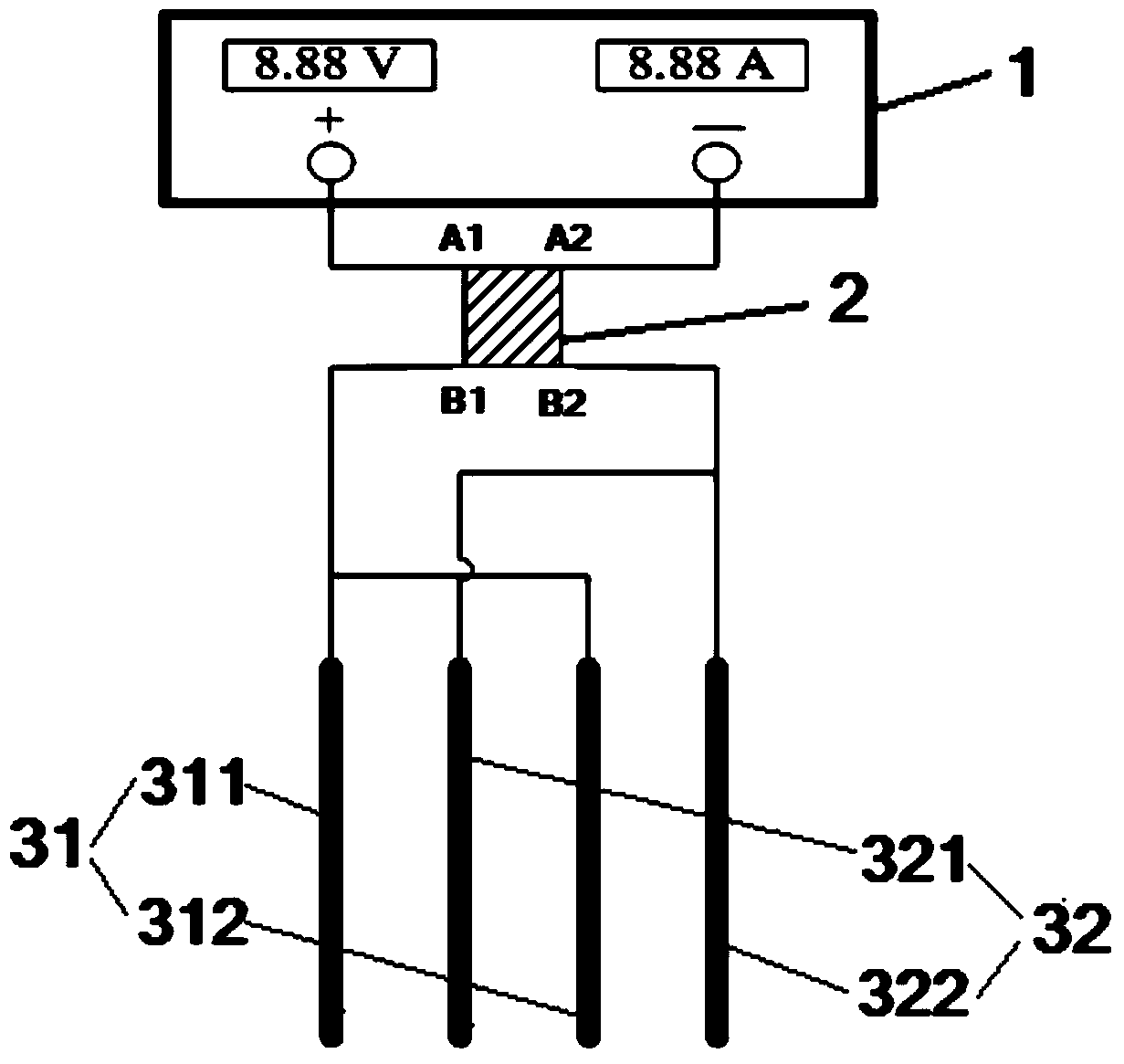

[0070] 2) Using the preferred electroflocculation device in Example 1, adjust the distance between two adjacent electrodes among the first aluminum electrode 311 , the first iron electrode 321 , the second aluminum electrode 312 , and the second iron electrode 322 to be 15 mm. Be that the sodium chloride solution of 0.75g / L is electrolytic solution with concentration, put electrolytic solution in the reaction tank 4 of aforementioned electrocoagulation device, then add the Cu-EDTA complexation of 2.5L step (1) in reaction tank 4 For waste water, mix Cu-EDTA complex waste water and electrolyte to obtain a mixed solution. The first aluminum electrode 311, the first iron e...

Embodiment 3

[0074] 1) Take Cu-EDTA complex wastewater, wherein the copper ion content is 50mg / L, the COD concentration content is 200mg / L, and the pH value is adjusted to 3.00 with hydrochloric acid;

[0075]2) Using the preferred electroflocculation device in Example 1, adjust the distance between two adjacent electrodes in the first aluminum electrode 311 , the first iron electrode 321 , the second aluminum electrode 312 , and the second iron electrode 322 to be 10 mm. Be that the sodium chloride solution of concentration 0.5g / L is electrolytic solution, electrolytic solution is put into the reaction tank 4 of aforementioned electrocoagulation device, then add the Cu-EDTA complexation of 2.5L step (1) in reaction tank 4 For waste water, mix Cu-EDTA complex waste water and electrolyte to obtain a mixed solution. The first aluminum electrode 311, the first iron electrode 321, the second aluminum electrode 312, and the second iron electrode 322 are all immersed in the mixed solution. Then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com