Device and treating method for treating organic waste gas through concerted catalysis of dielectric barrier discharge and low-temperature plasma

A low-temperature plasma, dielectric barrier discharge technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of easy coking, low safety, and electrode corrosion of dielectric barrier discharge tubes, and improve mineralization. efficiency, overcoming coking, reducing energy consumption and the production of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

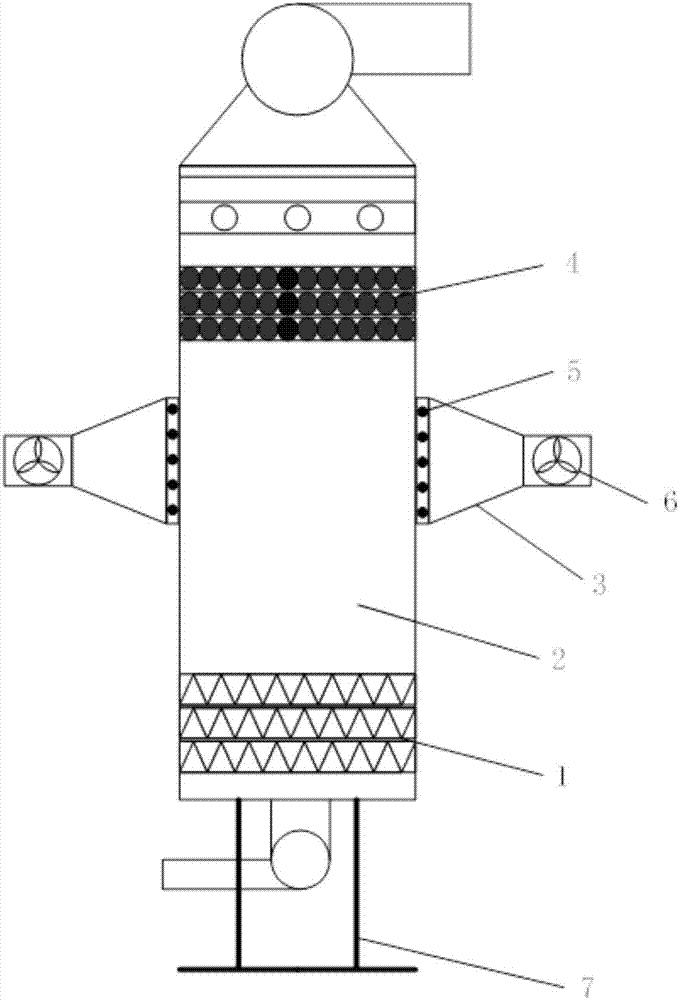

[0035] A device for treating industrial toluene-containing waste gas with dielectric barrier discharge low-temperature plasma synergistic catalytic treatment of organic waste gas, such as figure 1 As shown, it includes a main device and a low-temperature plasma generating device 3. The main device is divided into a filter bed 1, a reaction chamber 2, and an adsorption catalyst bed 4 from bottom to top. The low-temperature plasma generating device 3 is located in the reaction chamber. The outside of the chamber 2 is seamlessly connected with the reaction chamber 2.

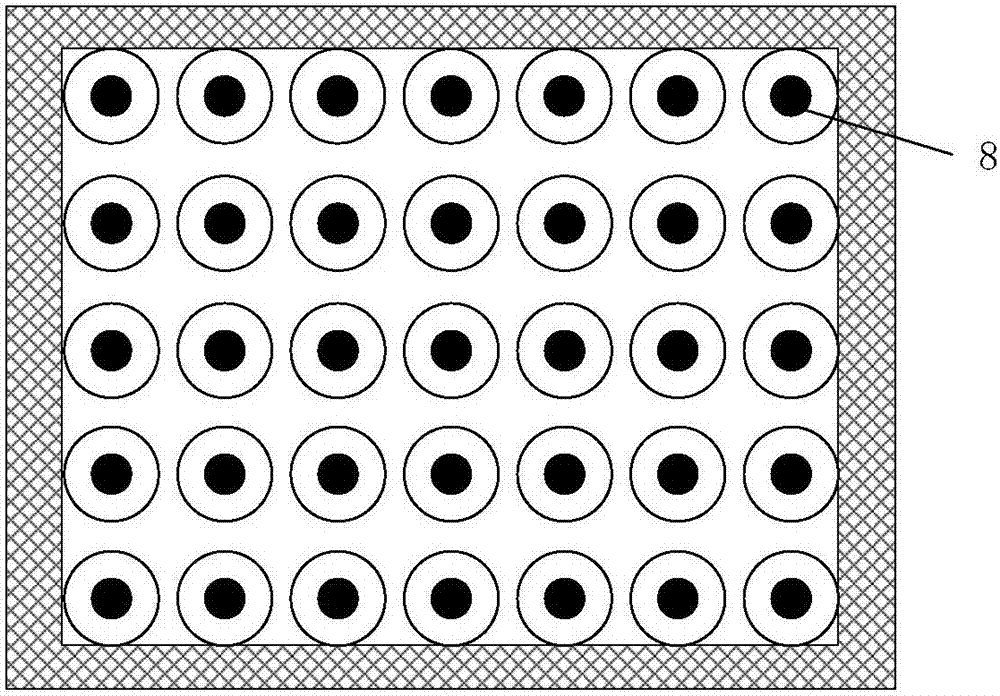

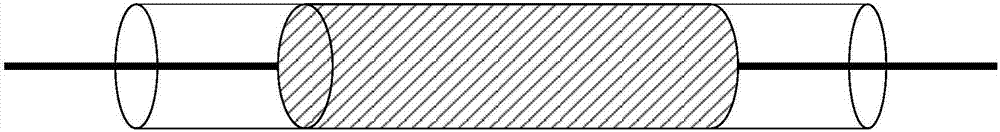

[0036] The low-temperature plasma generating device 3 is internally provided with a low-temperature plasma generating module 5 and an electric fan 6, and the low-temperature plasma generating module 5 is connected to the interior of the reaction chamber 2, such as figure 2 As shown, the low-temperature plasma generation module 5 is composed of 50 low-temperature plasma generators 8 arranged in parallel at equal in...

Embodiment 2

[0043] In order to process the same waste gas as in Example 1, the general structure of the device used in Example 2 is basically the same as that in Example 1, the only difference being:

[0044] The low-temperature plasma generation module is composed of 20 low-temperature plasma generators arranged in parallel at equal intervals; the length of the inner electrode in the low-temperature plasma generator is 35cm, the diameter is 5cm, and the thread pitch is 1.5mm; the cylindrical dielectric material The wall thickness is 3mm, the length is 30cm; the filter bed layer is 1 layer; the adsorption catalyst bed layer is 2 layers, the layer spacing is 3cm, the catalyst is alumina loaded with cerium oxide, and the particle size of alumina is 10mm; Other structures and parameters remain unchanged.

[0045] Adopt the same operation method of embodiment 1, utilize the device described in this embodiment 2 to be 50m to the waste gas flow rate before processing 3 / h, the waste gas whose ...

Embodiment 3

[0047] In order to process the same waste gas as in Example 1, the general structure of the device used in Example 3 is basically the same as that in Example 1, the only difference being:

[0048] The low-temperature plasma generation module is composed of 40 low-temperature plasma generators arranged in parallel at equal intervals; the length of the inner electrode in the low-temperature plasma generator is 25cm, the diameter is 3.5cm, and the thread pitch is 1mm; the cylindrical dielectric material is Ceramic, wall thickness is 2mm, length is 20cm; filter bed is 2 layers, bed thickness is 10cm, layer spacing is 3cm, filter bed filler is quartz sand; adsorption catalyst bed is 3 layers, bed thickness is 10cm, the interlayer spacing is 4cm, the catalyst is a molecular sieve loaded with cobalt oxide, and the particle size of alumina is 8mm; other structures and parameters of the device remain unchanged.

[0049] Adopt the same operation method of embodiment 1, utilize the devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com