Pretreatment equipment for coal slime before floatation feed

A coal slime flotation and treatment equipment technology, applied in flotation, solid separation, etc., can solve the problems of poor mixing effect of coal slurry and chemicals, difficulty in adding, unstable feeding pressure, etc., and achieve good promotion and use value, treatment The effect of wide particle size range and reasonable slurry flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

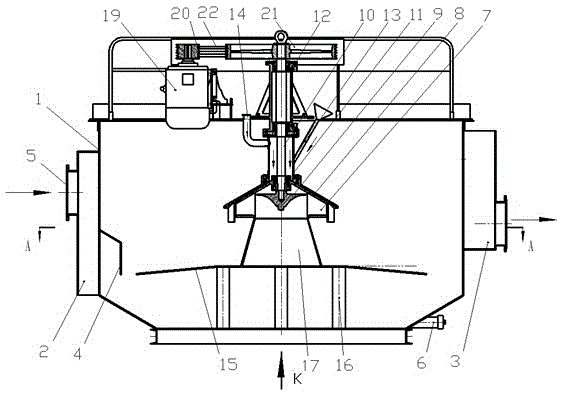

[0019] The invention includes a shell part, a stirring part, a false bottom part and a driving part.

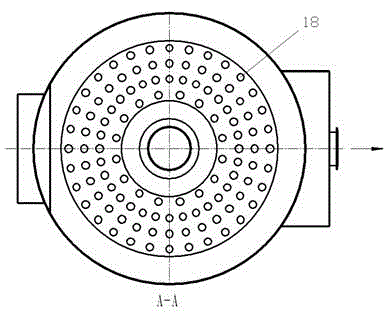

[0020] As shown in the figure, the housing part is composed of a housing 1 , an inlet box 2 , an outlet box 3 , a deflector 4 , a flange 5 , and an ore-drawing pipe 6 .

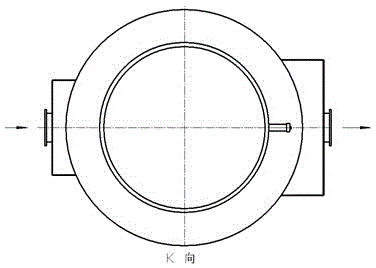

[0021] The casing 1 is an upright cylinder, and the bottom circumference of the cylinder of the casing 1 has an upwardly inclined ring, which allows more slurry to flow to the lower part of the false floor 15, increasing the probability of coal mineralization. There are feed box 2 and discharge box 3 on both sides of the cylinder of shell 1 respectively. Flanges 5 are welded on the feed box 2 and discharge box 3. The flanges 5 are connected with external equipment through pipelines.

[0022] A deflector 4 bent downward is installed on the inner wall of the housing inside the feeding box 2, and the deflector 4 plays the role of slurry drainage. The ore slurry flowing into the housing 1 can be diverted under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com