Ce-doped Fe-MOF ozone catalyst, and preparation and application thereof

A catalyst, fe-mofs technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problem of low removal and mineralization efficiency, acid site density Small size, low efficiency of catalytic ozone decomposition, etc., to achieve the effect of improving ozone mass transfer adsorption and catalytic decomposition rate, increasing mineralization degree, and promoting decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

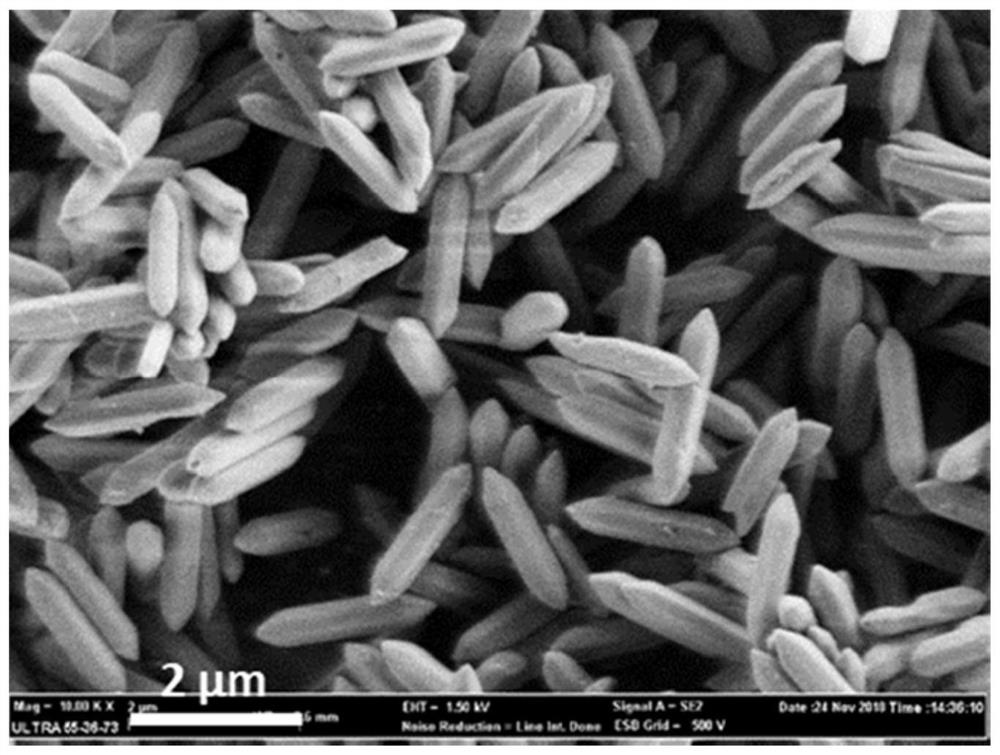

[0035] A kind of preparation method of Ce-doped Fe-MOFs ozone catalyst, form porous Ce-doped Fe-MOFs ozone catalyst by cerium ion doping Fe-MOFs hydrothermal self-assembly, as follows:

[0036] (1) Under magnetic stirring, according to the molar ratio of water and organic ligand fumaric acid is 500:1, the organic ligand is added into water, and the organic ligand solution is obtained after dissolution;

[0037] (2) A mixed metal salt (cerium nitrate hexahydrate and ferric chloride hexahydrate) with a molar ratio of n(Ce):n(Fe) of 0.20:0.80 was added to the organic ligand fumaric acid solution (where n (Ce): the total molar weight of n (Fe) and the mol ratio of fumaric acid are 1:1), stir to obtain Ce-doped Fe-MOFs ozone catalyst precursor mixed solution;

[0038] (3) Transfer the mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene. After hydrothermal reaction at 70 °C for 24 h, centrifuge, precipitate and wash, and vacuum dry at 100 °C for 24...

Embodiment 2

[0046] A kind of preparation method of Ce-doped Fe-MOFs ozone catalyst, as follows:

[0047] (1) Under magnetic stirring, according to the molar ratio of water and organic ligand fumaric acid is 500:1, the organic ligand is added to the aqueous solution, and the organic ligand solution is obtained after the dissolution is complete;

[0048] (2) A mixed metal salt (cerium nitrate hexahydrate and ferric chloride hexahydrate) with a molar ratio of n(Ce):n(Fe) of 0.15:0.85 was added to the organic ligand fumaric acid solution (where n( Ce): in the total molar weight of n (Fe) and the mol ratio of fumaric acid are 1:1), stir to obtain Ce-doped Fe-MOFs ozone catalyst precursor mixed solution;

[0049] (3) Transfer the mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene. After hydrothermal reaction at 70 °C for 24 h, centrifuge, precipitate and wash, and vacuum dry at 100 °C for 24 h to obtain porous Ce-doped Fe -MOFs ozone catalyst products.

[0...

Embodiment 3

[0052] A kind of preparation method of Ce-doped Fe-MOFs ozone catalyst, as follows:

[0053] (1) Under magnetic stirring, according to the molar ratio of water and organic ligand fumaric acid is 500:1, the organic ligand is added to the aqueous solution, and the organic ligand solution is obtained after the dissolution is complete;

[0054] (2) A mixed metal salt (cerium nitrate hexahydrate and ferric chloride hexahydrate) with a molar ratio of n(Ce):n(Fe) of 0.10:0.90 was added to the organic ligand fumaric acid solution (where n( Ce): in the total molar weight of n (Fe) and the mol ratio of fumaric acid are 1:1), stir to obtain Ce-doped Fe-MOFs ozone catalyst precursor mixed solution;

[0055] (3) Transfer the mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene. After hydrothermal reaction at 70 °C for 24 h, centrifuge, precipitate and wash, and vacuum dry at 100 °C for 24 h to obtain porous Ce-doped Fe -MOFs ozone catalyst products.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com