Preparation method of zinc oxide/zinc titanite nucleocapsid nanowire composite photocatalyst and application thereof

A zinc oxide nanowire, core-shell nanotechnology, applied in the field of environmental pollution control, can solve the problem of harsh requirements, zinc oxide/zinc titanate nanowire composite photocatalyst photocatalytic properties have not been better developed, difficult to achieve, etc. problem, to achieve the effect of improving separation efficiency, widening the range of photoresponse, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

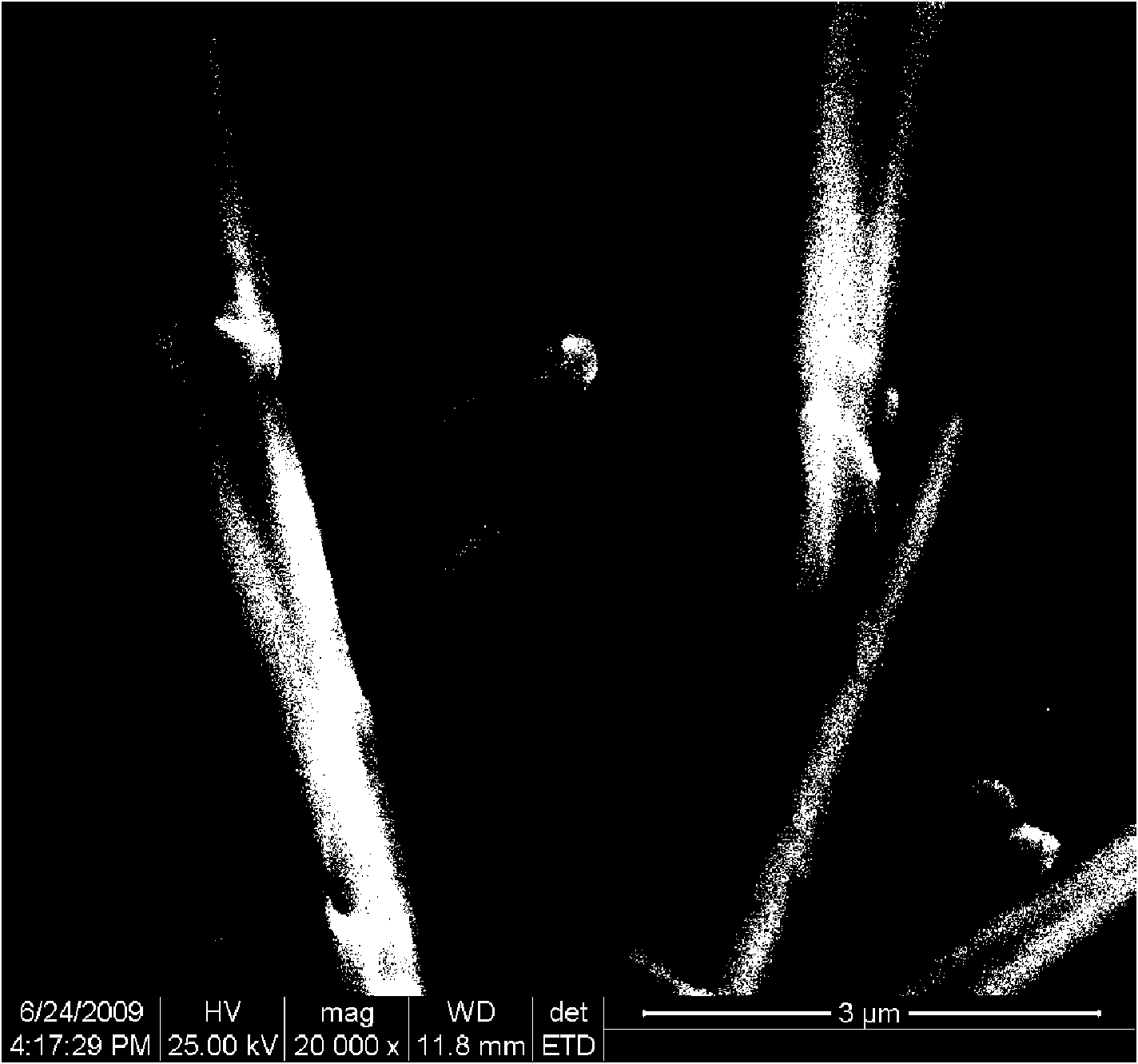

[0026] Preparation of ZnO nanowire template: firstly, 0.58gZnSO 4 .7H 2 Dissolve 60ml of NaOH (0.5M) under O stirring, then add 10ml of hydrazine hydrate (N 2 h 4 .H 2 (0, 80%), then the solution was transferred to a 100ml polytetrafluoroethylene reactor, heated to 90°C, and maintained for 5h. Naturally cooled to room temperature, centrifuged at 8000 rpm for 5 min, washed with water and washed with alcohol three times each to obtain a white solid. Vacuum drying at 60°C for 12 hours to obtain a zinc oxide sample.

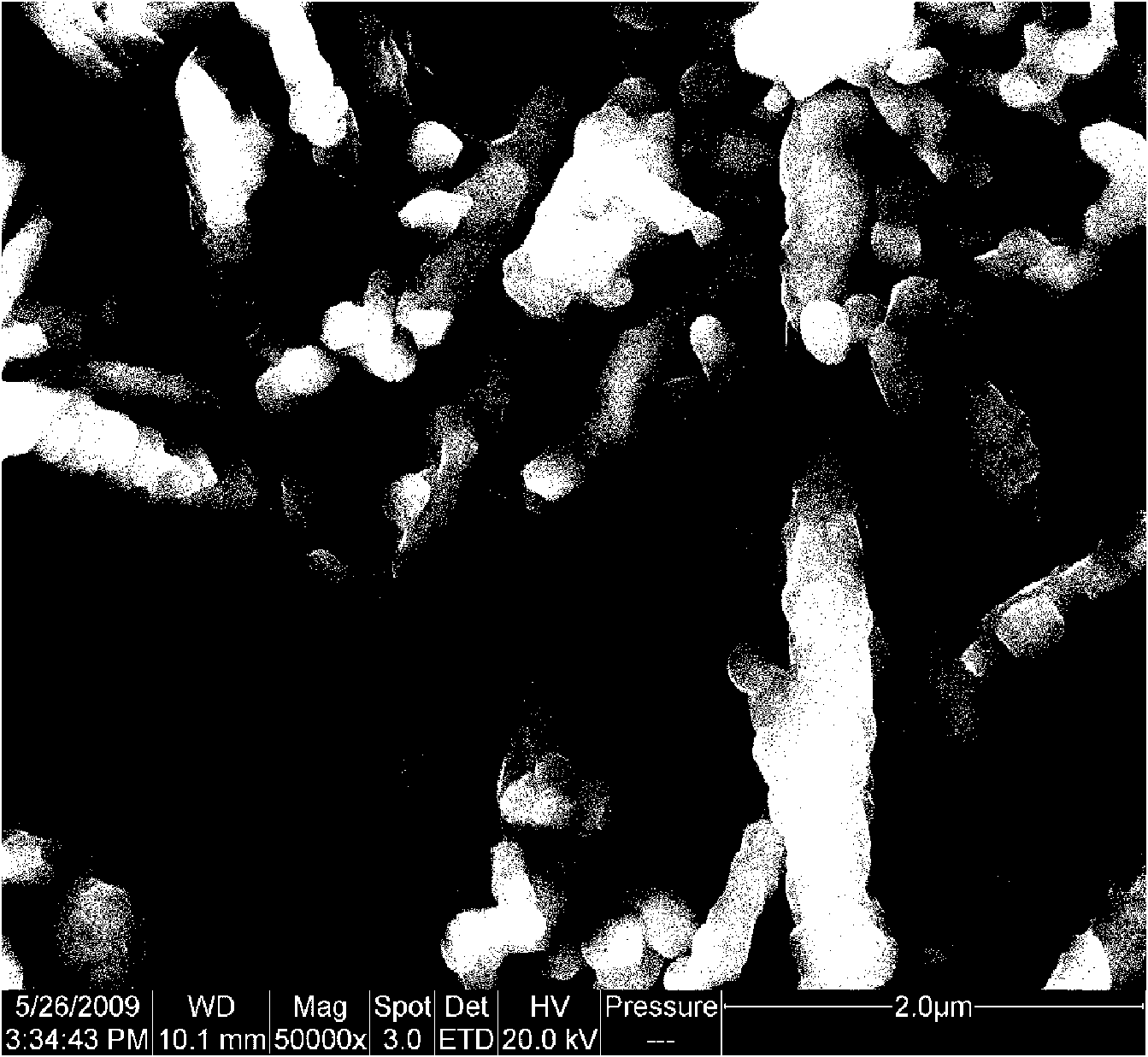

[0027] 2) Preparation of zinc oxide / titanium dioxide core-shell structure: using zinc oxide nanowires as a template, the zinc oxide / titanium dioxide core-shell structure was prepared by the sol-gel method. The specific method is as follows: disperse 20 mg of zinc oxide nanowires in 16 ml of n-butyl In alcohol, sonicate for 5 min to form a homogeneous suspension. After that, 20 mg CTAB and 0.5 ml deionized water were added and stirred for 45 min. Dissolve 0.05m...

Embodiment 2

[0030] According to the preparation method of the present invention in Example 1, only the addition of tetrabutyl titanate in the preparation step of the zinc oxide / titanium dioxide core-shell structure is changed to 0.1ml, and the zinc oxide / zinc titanate core-shell nanowire composite optical fiber is obtained. catalyst.

Embodiment 3

[0032] According to the preparation method of the present invention in Example 1, only the addition amount of tetrabutyl titanate in the preparation step of the zinc oxide / titanium dioxide core-shell structure is changed to 0.2ml, and the zinc oxide / zinc titanate core-shell nanowire composite optical fiber is obtained. catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com