Adsorbent, preparation process thereof and application of adsorbent to purification of ammonia-nitrogen wastewater with medium-low concentration

A technology of ammonia nitrogen wastewater and preparation process, which is applied in the direction of adsorption of water/sewage treatment, other chemical processes, water pollutants, etc., can solve the problems of high regeneration cost, short service life and high operating cost of adsorbents, and achieve cheap raw materials and reunion The effect of light degree and fast settlement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The mass percentage of sawdust is 99.7%, Fe(OH) 3 The mass percentage is 0.3%.

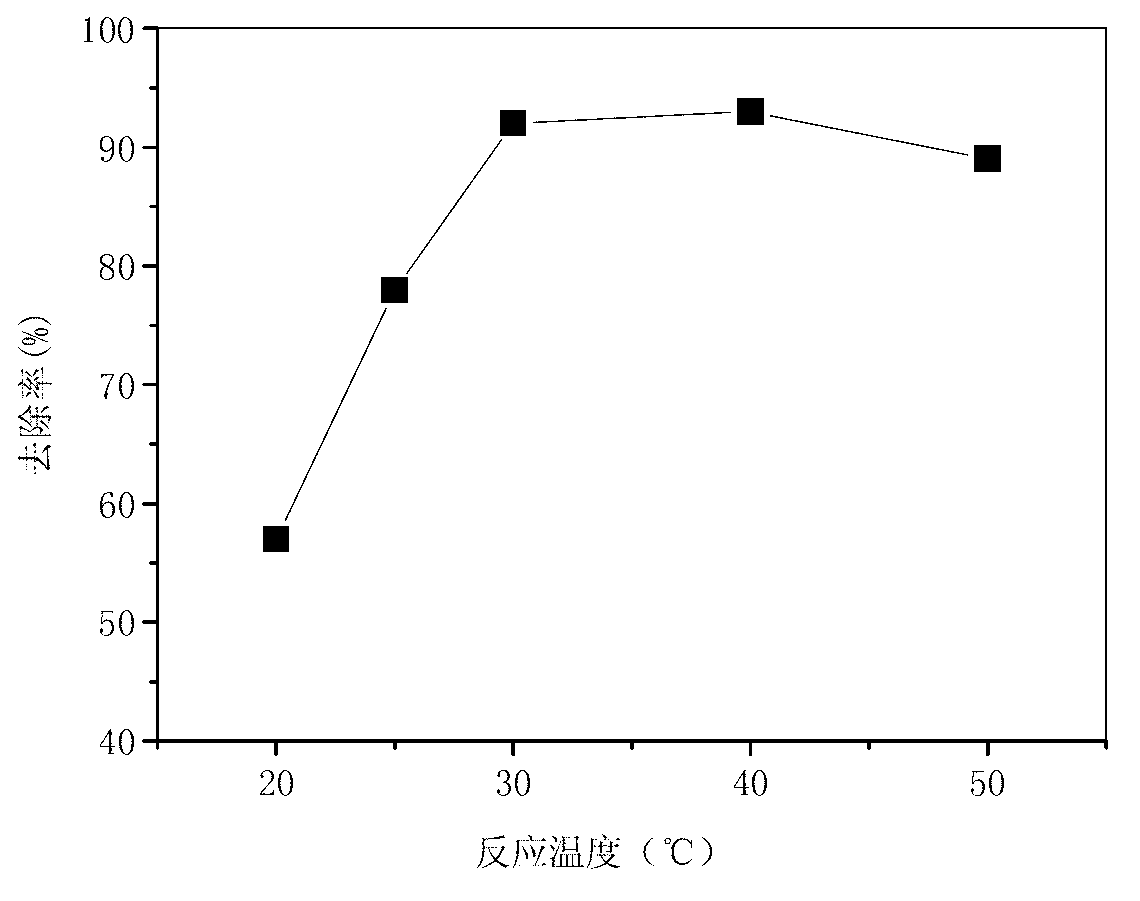

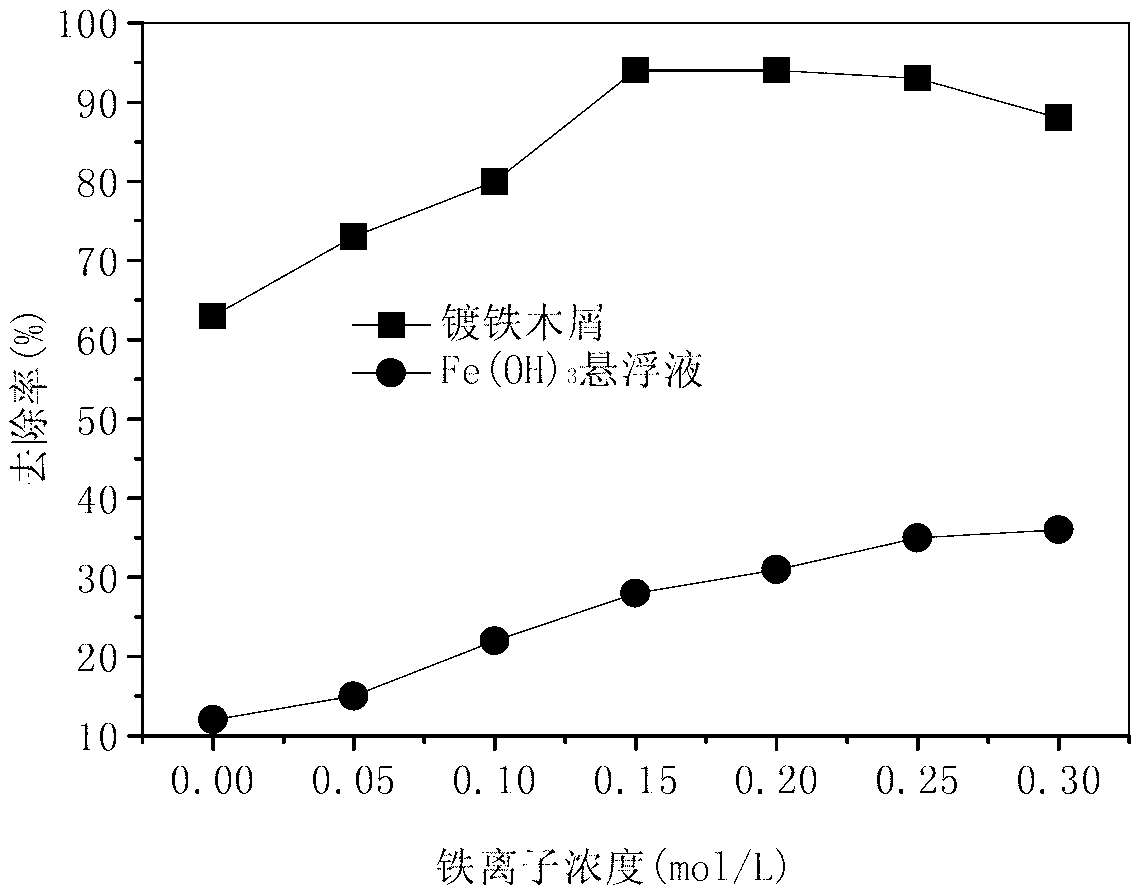

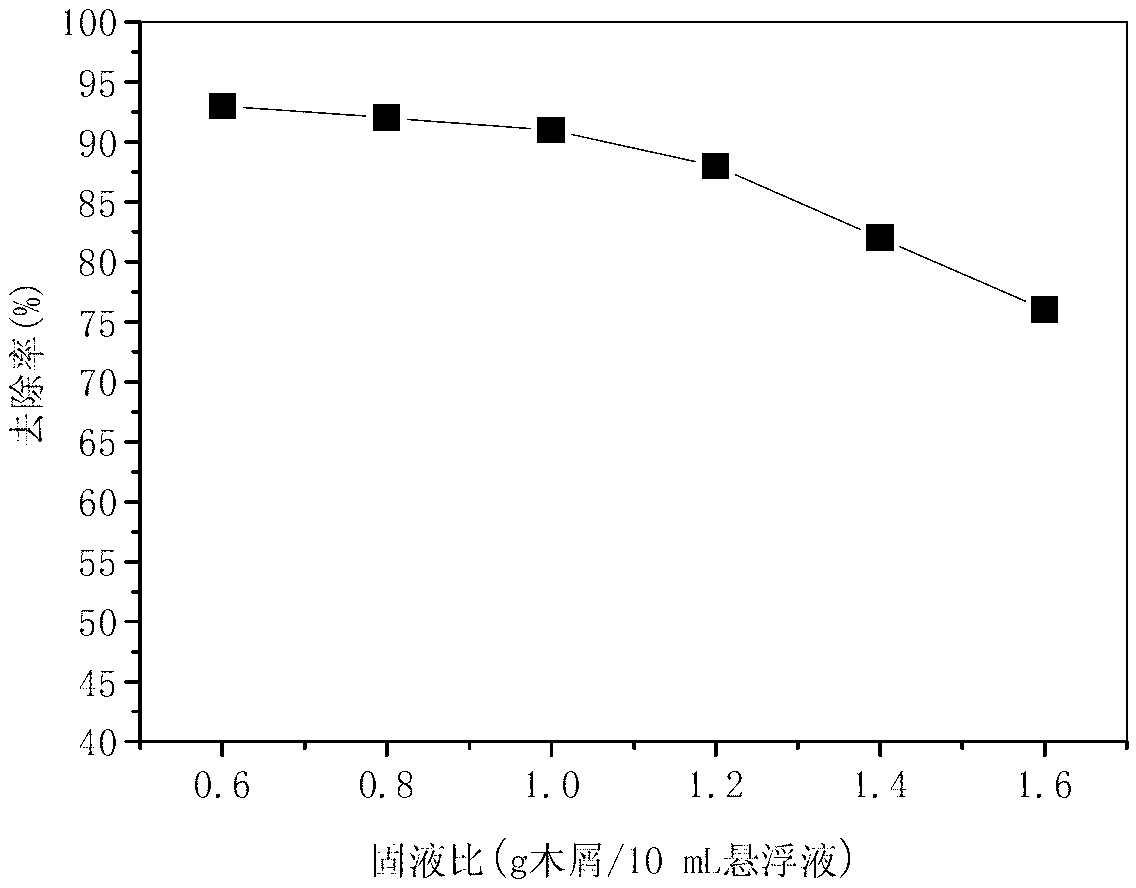

[0037] Preparation of iron-plated sawdust: the mass percentage of sawdust particles with a particle size of 198-350 μm accounts for 81%, and the concentration of FeCl is 0.15 mol / L 3 The Fe(OH) produced by the reaction of the solution with the NaOH solution 3 suspension, then wood chips and Fe(OH) 3 After the suspension was fully mixed with a solid-to-liquid ratio of 1.0 g / 10 mL, it was hydrothermally treated at a temperature of 40 °C for 2 h, and the product was washed to neutral, filtered with suction, and dried to obtain the iron-plated sawdust adsorbent.

[0038] Purification and treatment of ammonia nitrogen wastewater by iron-plated sawdust adsorbent: initial NH in wastewater 4 + The concentrations of -N and COD were 102 mg / L and 355 mg / L respectively, the reaction temperature was controlled at 25°C, the pH of the wastewater was adjusted to 9, the amount of iron-plated sawdust ads...

Embodiment 2

[0040] The mass percentage of sawdust is 99.4%, Fe(OH) 3 The mass percentage is 0.6%.

[0041] Preparation of iron-plated sawdust: the mass percentage of sawdust particles with a particle size of 198-350 μm accounts for 85%, and the concentration of FeCl is 0.20 mol / L 3 The Fe(OH) produced by the reaction of the solution with the NaOH solution 3 suspension, then wood chips and Fe(OH) 3 After the suspension was fully mixed at a solid-to-liquid ratio of 0.8 g / 10 mL, it was hydrothermally treated at a temperature of 30 °C for 3 h, and the product was washed to neutrality, filtered with suction, and dried to obtain the iron-plated sawdust adsorbent.

[0042] Purification and treatment of ammonia nitrogen wastewater by iron-plated sawdust adsorbent: initial NH in wastewater 4 + -N, Zn 2+ The concentrations were 94 mg / L and 4.5 mg / L respectively, the reaction temperature was controlled at 35°C, the pH of the wastewater was adjusted to 10, the amount of adsorbent was 3.5 g / L, an...

Embodiment 3

[0044] The mass percentage of sawdust is 99.4%, Fe(OH) 3 The mass percentage is 0.6%.

[0045] Preparation of iron-plated sawdust: the mass percentage of sawdust particles with a particle size of 198-350 μm accounts for 85%, and the concentration of FeCl is 0.20 mol / L 3 The Fe(OH) produced by the reaction of the solution with the NaOH solution 3 suspension, then wood chips and Fe(OH) 3 After the suspension was fully mixed at a solid-to-liquid ratio of 0.8 g / 10 mL, it was hydrothermally treated at a temperature of 50 °C for 1.5 h. The product was washed to neutrality, filtered with suction, and dried to obtain the iron-plated sawdust adsorbent.

[0046] Purification and treatment of ammonia nitrogen wastewater by iron-plated sawdust adsorbent: initial NH in wastewater 4 + -N, AsO 4 3- The concentrations were 147 mg / L and 0.9 mg / L respectively, the reaction temperature was controlled at 28°C, the pH of the wastewater was adjusted to 9, the amount of adsorbent was 4.8 g / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com