Cleaning method for MOCVD equipment

A cleaning and equipment technology, applied in the cleaning field of MOCVD equipment, can solve problems such as film defects, increase the work intensity of operators, and residual deposits are not cleaned up, and achieve the effect of short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] As mentioned in the background technology, manual cleaning of the residual deposits on the inner wall of the MOCVD reaction chamber not only takes a lot of time, but the production efficiency and production capacity of the MOCVD equipment cannot be maximized, and the degree of manual cleaning is inconsistent each time. , the residual deposits may not be cleaned up due to operator error.

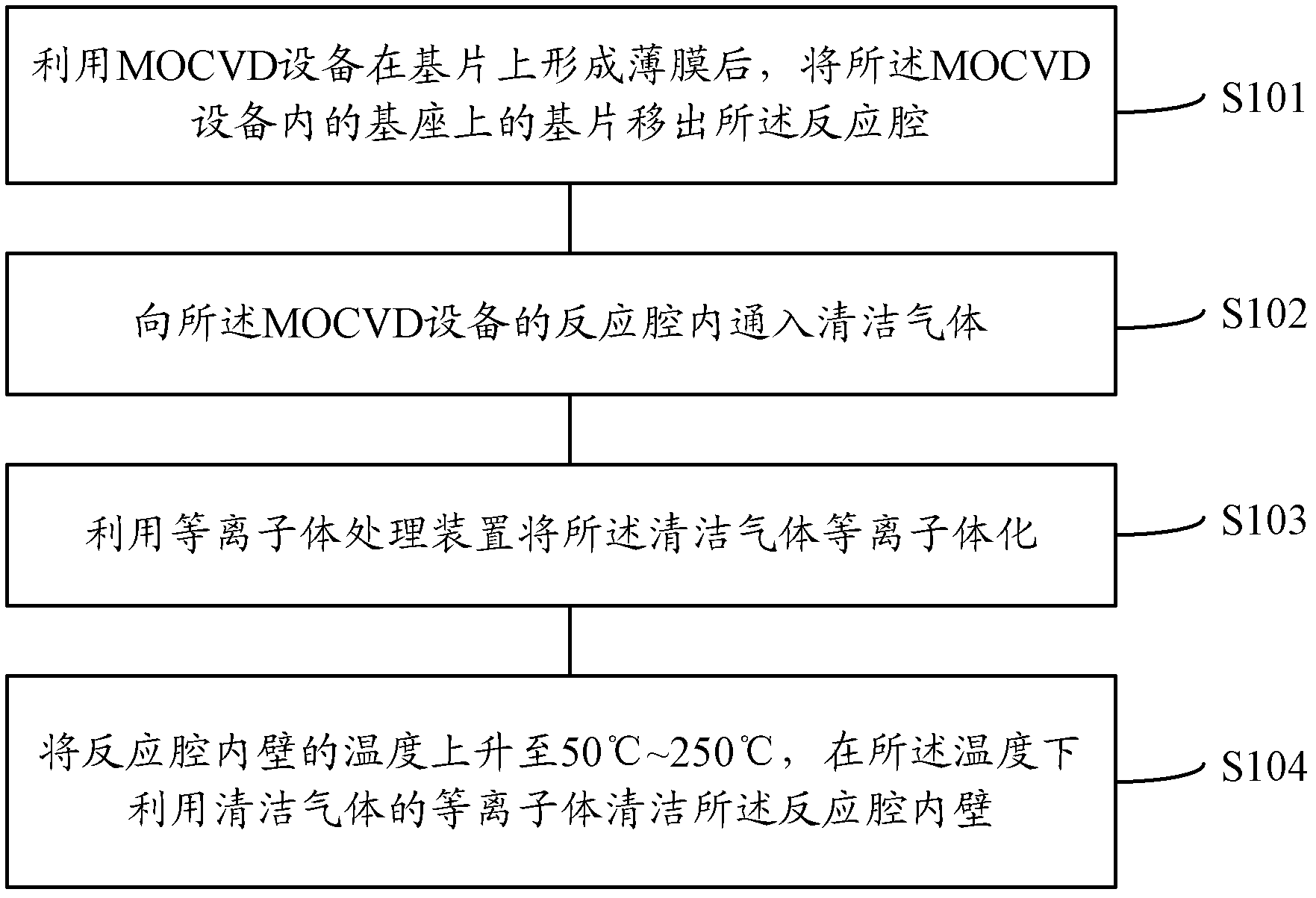

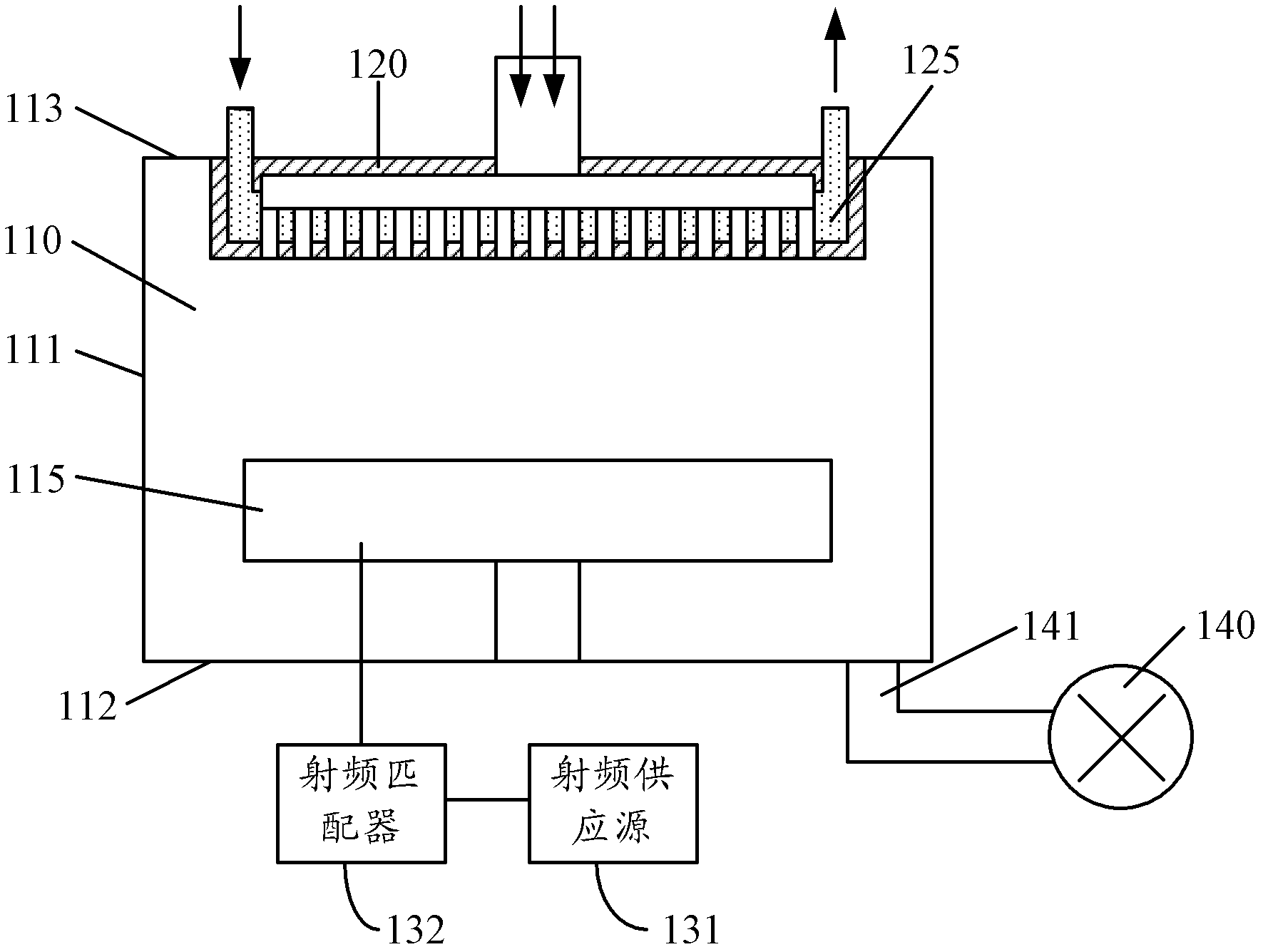

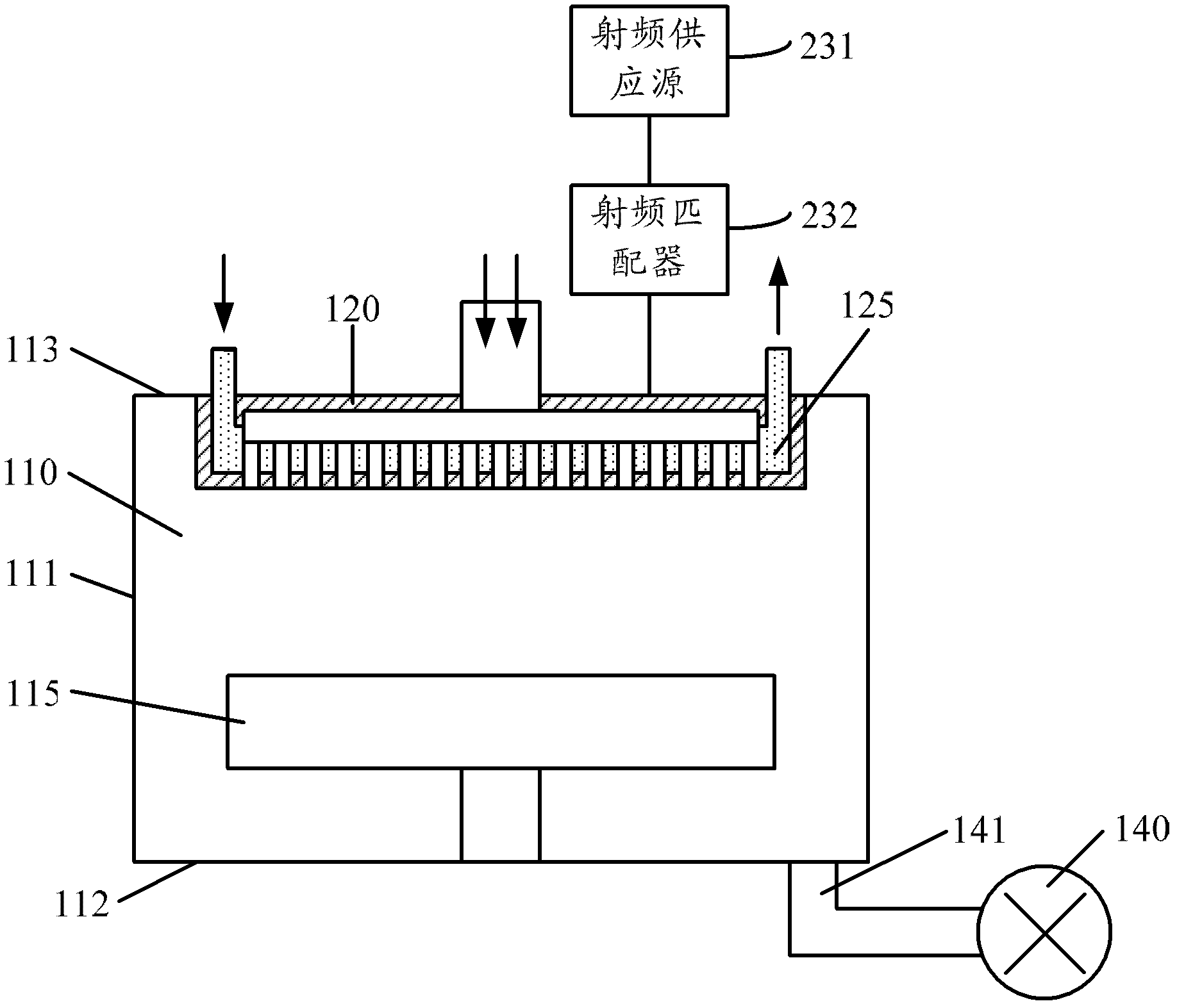

[0027] For this reason, the inventor has proposed a kind of cleaning method of MOCVD equipment, comprises: in the reaction chamber of described MOCVD equipment, pass cleaning gas; The temperature is raised to 50° C. to 250° C., at which temperature the inner wall of the reaction chamber is cleaned with a plasma of cleaning gas. The inventors have found through research that as the temperature increases, the removal rate of the residual deposits on the inner wall of the reaction chamber by the plasma of the cleaning gas gradually becomes faster. The inner wall of the reaction chamber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com