Method for green synthesis of nanometer zero-valent iron suspension liquid with peels or seed kernels

A nano-zero-valent iron, green synthesis technology, applied in nanotechnology, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as toxic chemical reagents, achieve good biodegradability, good application value, Fast removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

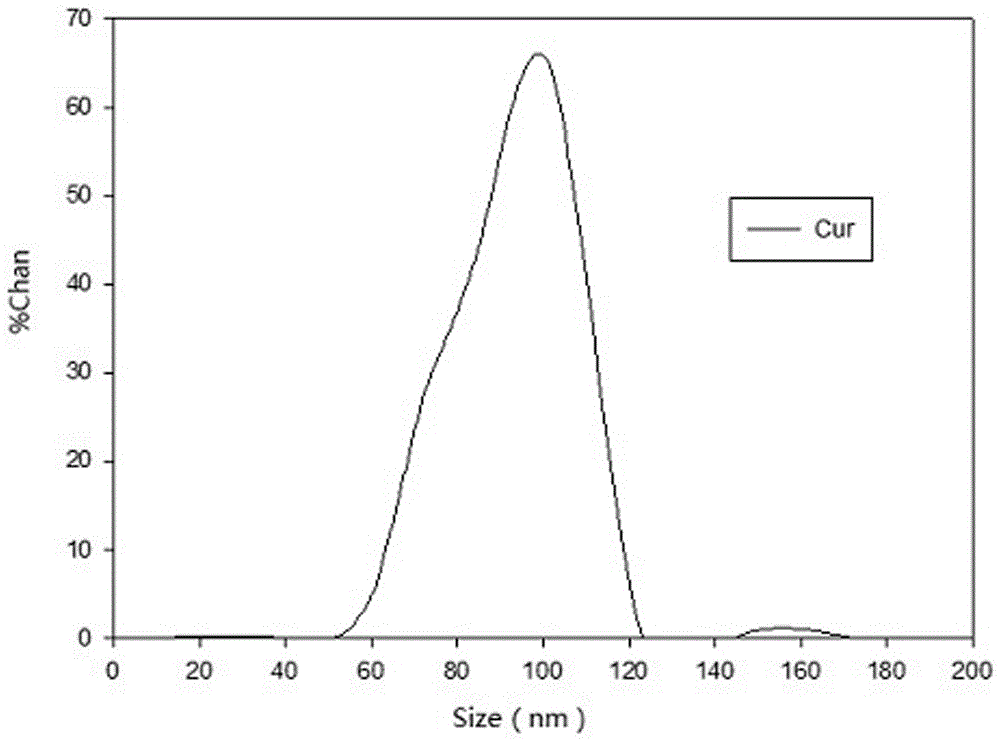

Embodiment 1

[0020] A method for synthesizing nano zero-valent iron suspension with peel or kernel green, comprising the steps:

[0021] (1) Extraction of total phenols: Dry the grape seeds in a blast drying oven at 80°C for 8 hours, grind them into powder with a pulverizer, weigh 4g of grape seed powder and add it to the colorimetric tube, and add it to the colorimetric tube Add a 60% ethanol solution with a solid-liquid ratio of 1:15, pass nitrogen gas with a purity of 99.9% for 5 minutes, plug the cap of the colorimetric tube tightly to prevent air from entering, heat it in a water bath at 80°C, and use a centrifuge at 13000r Centrifuge the total phenol extract at a speed of 1 / min, take the supernatant as a reducing agent for preparing zero-valent iron, measure the content of total phenol in the supernatant by Folin-Ciocalteu colorimetry, and take the total phenol in the supernatant The concentration was diluted to 0.2mg / mL.

[0022] (2) Preparation of ferric chloride solution: Weigh 1...

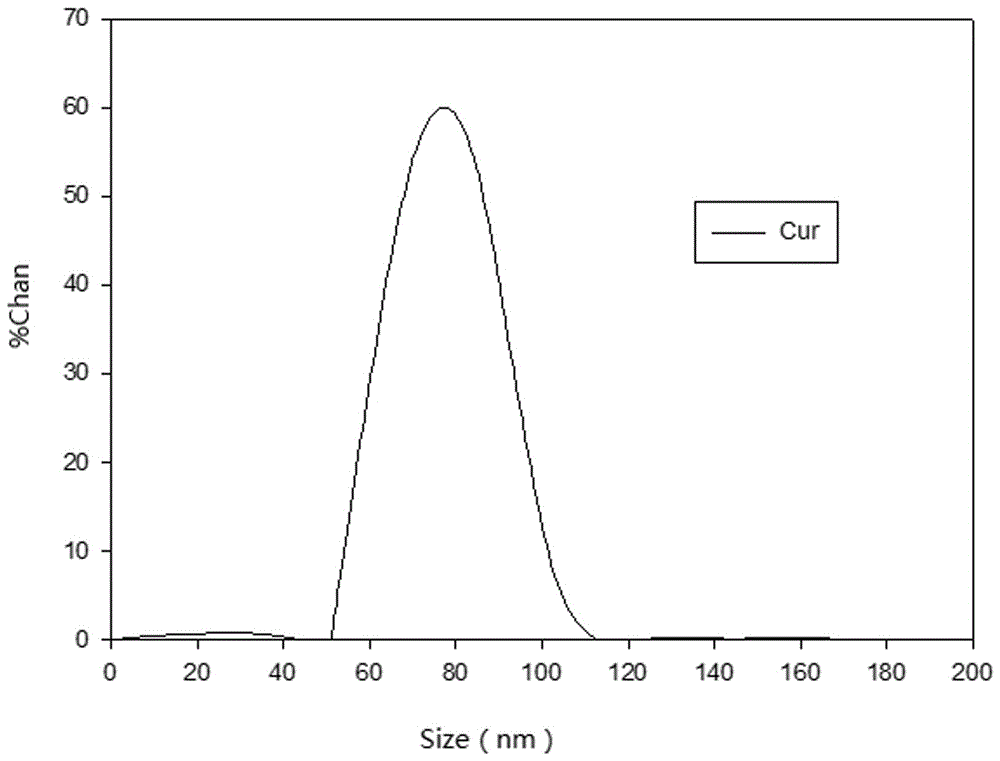

Embodiment 2

[0026] A method for synthesizing nano zero-valent iron suspension with peel or kernel green, comprising the steps:

[0027] (1) Extraction of total phenols: Dry the mango peel in a blast drying oven at 90°C for 8 hours, grind it into powder with a pulverizer, weigh 4g of mango peel powder and add it to the colorimetric tube, and add it to the colorimetric tube Add a 60% ethanol solution with a ratio of solid to liquid of 1:20, pass nitrogen gas with a purity of 99.9% for 5 minutes, plug the cap of the colorimetric tube tightly to prevent air from entering, heat it in a water bath at 90°C, and use a centrifuge at 14000r Centrifuge the total phenol extract at a speed of 1 / min, take the supernatant as a reducing agent for preparing zero-valent iron, measure the content of total phenol in the supernatant by Folin-Ciocalteu colorimetry, and take the total phenol in the supernatant The concentration was diluted to 0.2mg / mL.

[0028] (2) Preparation of ferric chloride solution: Weig...

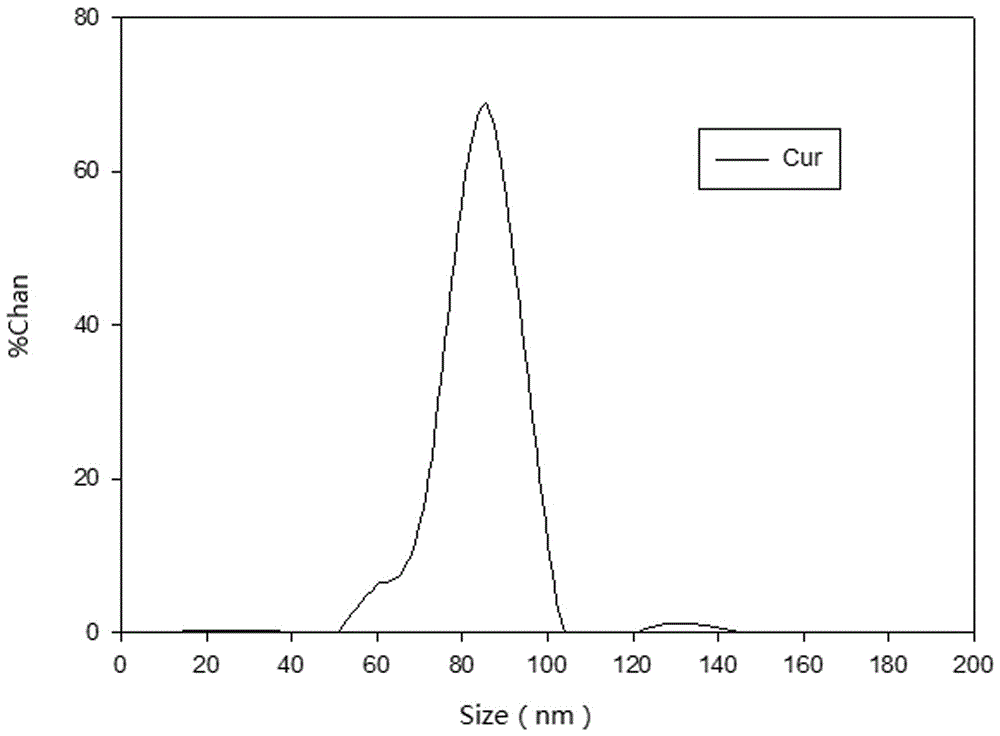

Embodiment 3

[0032] A method for synthesizing nano zero-valent iron suspension with peel or kernel green, comprising the steps:

[0033] (1) Extraction of total phenols: dry pomegranate peels in a blast drying oven at 80°C for 9 hours, grind them into powder with a pulverizer, weigh 4g of pomegranate peels powder and add them to a colorimetric tube. Add 60% ethanol solution with a solid-liquid ratio of 1:20 to the colorimetric tube, pass nitrogen gas with a purity of 99.9% for 5 minutes, plug the cap of the colorimetric tube tightly to prevent air from entering, heat in a water bath at 90°C, and use The centrifuge centrifuges the total phenol extract at a speed of 15000r / min, takes the supernatant as a reducing agent for preparing zero-valent iron, measures the content of total phenol in the supernatant by Folin-Ciocalteu colorimetry, and takes the supernatant The concentration of total phenols in the solution was diluted to 0.2mg / mL.

[0034] (2) Preparation of ferric chloride solution: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com