Method for preparing hydrotalcite by adopting brucite

A brucite and hydrotalcite technology, which is applied in the direction of alumina/aluminum hydroxide, can solve the problems of increasing the complexity of the process, taking a long time, and the process is cumbersome, so as to improve the utilization value, reduce the production cost, and reduce the source of raw materials. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Select 4.2g brucite and 1.8gAl(OH) 3 , mix it evenly with zirconia balls with a ratio of Φ10mm: Φ6mm=50:120, the mass ratio of balls to materials is 50:1, put them into a 250mL zirconia ball mill jar, and mill at a speed of 200r in a planetary ball mill / min, ball mill for 6h, add 2mL of deionized water, continue to mill at a speed of 200r / min, ball mill for 6h, take out the material and put it into a 500mL beaker, pour 200mL of 0.1mol / L Na 2 CO 3 The solution was stirred in a water bath at 80°C for 1 hour at a stirring speed of 500r / min, washed in a centrifuge at a speed of 1500r / min, and dried at 80°C to obtain hydrotalcite;

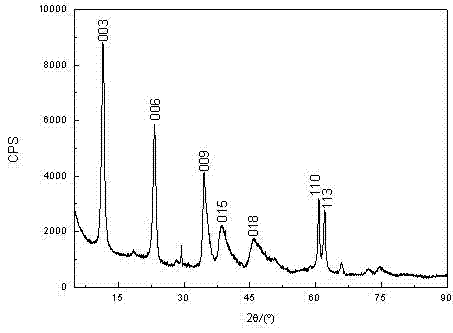

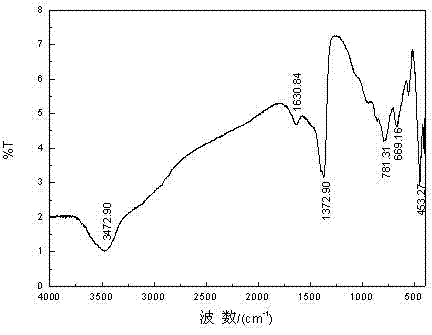

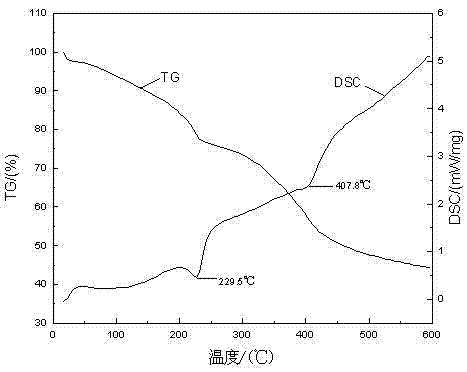

[0035] The XRD, FTIR and TG-DSC curves of the product are as follows Figure 1~3 As shown, the FTIR figure shows that the product has hydroxyl and CO 32- , 3472.90cm -1 It is the vibration absorption peak of hydroxyl group (laminate), 1372.90cm -1 for CO 3 2- (interlayer) vibration absorption peak, 453.27.cm -1 It is the characteristic a...

Embodiment 2

[0037] Select 4.2g brucite and 1.8gAl(OH) 3 , mix it evenly with zirconia balls with a ratio of Φ10mm: Φ6mm=50:120, the mass ratio of balls to materials is 50:1, put them into a 250mL zirconia ball mill jar, and mill at a speed of 100r in a planetary ball mill / min, ball mill for 6h, add 2mL of deionized water, continue to mill at a speed of 100r / min, ball mill for 2h, take out the material and put it into a 500mL beaker, pour 200mL of 0.1mol / L Na 2 CO 3 The solution was stirred in a water bath at 80°C for 1 hour at a stirring speed of 500r / min, washed in a centrifuge at a speed of 1500r / min, and dried at 80°C to obtain hydrotalcite.

Embodiment 3

[0039] Choose 3.6g brucite and 2.4gAl(OH) 3 , mix it evenly with zirconia balls with a ratio of Φ10mm: Φ6mm=50:120, the mass ratio of balls to materials is 50:1, put them into a 250mL zirconia ball mill jar, and mill at a speed of 250r in a planetary ball mill / min, ball mill for 4h, add 3mL of deionized water, continue to mill at a speed of 250r / min, ball mill for 2h, take out the material and put it into a 500mL beaker, pour 200mL of 0.05mol / L Na 2 CO 3 The solution was stirred in a water bath at 80°C for 1 hour at a stirring speed of 500r / min, washed in a centrifuge at a speed of 1500r / min, and dried at 80°C to obtain hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com