Sewage treatment system and application thereof

A sewage treatment system and sewage treatment technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high ammonia nitrogen concentration, low nitrification efficiency, and nitrification low bacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

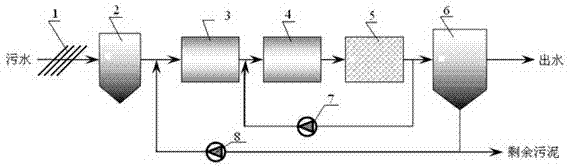

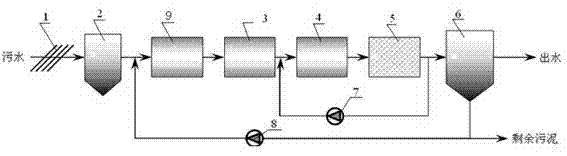

[0022] Typical traditional sewage nitrogen and phosphorus removal treatment system, the schematic diagram of the treatment process is as follows figure 1 As shown, it includes sewage treatment grid 1, grit chamber 2, anaerobic tank 3, anoxic tank 4, aerobic tank 5, and secondary sedimentation tank 6. After being treated by grid 1, the sewage enters grit chamber 2, and the grit chamber The mixed solution obtained after the effluent from the pool 2 is treated by the biological treatment unit composed of the anaerobic pool 3, the anoxic pool 4, and the aerobic pool 5 enters the secondary sedimentation pool 6;

[0023] The secondary settling tank 6 is provided with two outlets, one is the discharge outlet of the treated sewage, and the other is the discharge outlet of the excess sludge, and the discharge outlet of the excess sludge is provided with a bypass after the sludge return pump 8 will be used The remaining sludge discharged from the secondary settling tank 6 is returned t...

Embodiment 2

[0031] Utilize the typical traditional sewage denitrification and dephosphorization treatment system described in Example 1 and the sewage treatment system of the present invention to respectively treat the sewage of Shanghai Bailonggang sewage treatment plant whose water intake is long-distance pipeline transport sewage, and treat The amount of sewage is 200L / d, the COD of sewage influent is 318.6 mg / L, the ammonia nitrogen is 29.75 mg / L, and the sulfide content is 13.1 mg / L.

[0032]During the winter low-temperature operation stage (January to February), the effluent ammonia nitrogen of the sewage treatment system of the present invention is 4.70±1.91 mg / L, while the effluent ammonia nitrogen of a typical traditional sewage denitrification and phosphorus removal system is 17.76±4.74 mg / L L;

[0033] In the period of normal temperature operation (4~6 months), the final ammonia nitrogen in the effluent of the sewage treatment system of the present invention is 1.23±1.12 mg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com