Preparation method of multi-scale double-interface metal ceramic powder

A cermet and ceramic powder technology, which is applied in the field of multi-scale double-interface cermet powder preparation, can solve the problems of material wear performance restriction, increased wear, decreased toughness, etc., and achieves the effects of good strength and toughness and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

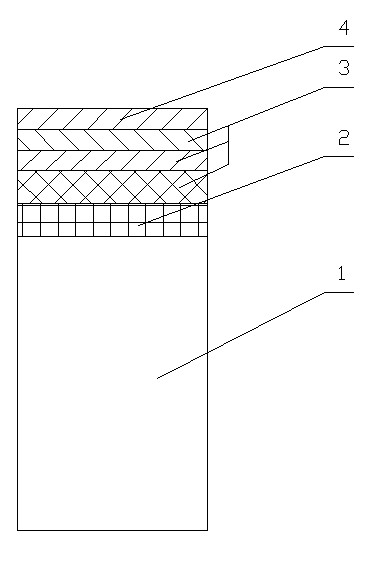

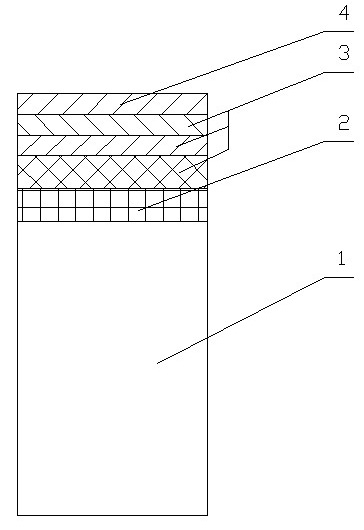

[0030] like figure 1 As shown, for the specific multi-scale dual-interface WC-Co cermet powder

[0031] Ball milling: Select conventional micron-sized WC powder (15-45 microns), put the powder into a ball mill tank and use ethanol as a process control agent for wet ball milling, the ball-to-material ratio is 20:1, the speed is 250 rpm, and the ball milling time is 72 hour, 36 hours, 12 hours;

[0032] Sieving: Sieve the above powders milled for different times to obtain nanoscale WC powder (25-50nm), submicron WC powder (300-500nm) and micron WC powder (1-5 microns);

[0033] Coating: Co-coated WC particles were then prepared by electroless plating on the above-mentioned WC powders with different particle sizes. The specific process is as follows: put WC in an anhydrous ethanol solution with a concentration of about 30-60%, ultrasonically clean it for about 15 minutes to obtain WC particles with a clean surface, and soak the purified WC particles in saturated NaCl solu...

example 2

[0038] like figure 1 As shown, for the specific multi-scale dual-interface WC-Ni cermet powder

[0039] Ball milling: Select conventional micron-sized WC powder (15-45 microns), put the powder into a ball mill tank and use argon as a protective gas for dry and wet ball milling. 48 hours, 24 hours, 6 hours;

[0040] Sieving: Sieve the above powders milled for different times to obtain nanoscale nanoscale WC powder (50-80nm), submicron scale WC powder (600-800nm) and micron scale WC powder (5-8μm);

[0041] Coating: Ni-coated WC particles were prepared by electroless plating on the above-mentioned WC powders with different particle sizes. The specific process is as follows: Purify and activate the above-mentioned WC powders with different particle sizes, then take cobalt sulfate with a concentration of 20 g / L, tartaric acid with a concentration of 20 g / L and EDTA with a concentration of 10 g / L and dissolve them in distilled water respectively. Then mix the three solutio...

example 3

[0046] like figure 1 As shown, for the specific multi-scale double-interface TiC-Fe cermet powder

[0047] Ball milling: Select conventional micron-sized TiC powder (15-45 microns), put the powder into a ball mill tank and use ethanol as the process control agent for wet ball milling, the ball-to-material ratio is 20:1, the speed is 200 rpm, and the ball milling time is 72 hour, 36 hours, 12 hours;

[0048] Sieving: Sieve the above powders milled for different times to obtain nanoscale TiC powder (25-50nm), submicron WC powder (300-500nm) and micron WC powder (1-5 microns);

[0049] Coating: Fe-coated TiC particles were prepared by electroless plating on the above-mentioned ball-milled TiC powders with different particle sizes. First, purify and activate the above-mentioned TiC powders with different particle sizes, and then take ferrous sulfate with a concentration of 8g / L, sodium hypophosphite with a concentration of 30~40g / L, potassium sodium tartrate with a concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com