Method for preparing water dispersible metal nano-particles

A metal nanoparticle and dispersed technology, applied in interdisciplinary fields, can solve the problems of complex metal nanoion technology and poor water dispersibility, and achieve the effect of strong operability, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing water-dispersed metal nanoparticles: (1) preparing an aqueous dispersion of nanocellulose with a mass concentration of nanocellulose between 0.01% and 5%; (2) adding a certain amount of metal ions or metal ions The complex is added to the nanocellulose dispersion, the mass ratio of the metal ion or the metal ion complex to the cellulose is between 1:300 and 1:3, and the mechanical stirring is evenly mixed; (3) at a temperature of 30 to 90°C , adding a reducing agent to reduce metal ions, and aging at the reaction temperature for 10 minutes to 2 days. (4) centrifuging and washing the aged dispersion liquid for 1 to 6 times to obtain water-dispersed metal nanoparticles.

[0022] Above-mentioned nanocellulose can be with cotton fiber, hemp fiber, wood pulp fiber, bamboo fiber or microcrystalline cellulose, and the metal ion that adds can be any metal ion or its For the complex, the reducing agent used may be any one of hydrazine hydrate, sodium boro...

Embodiment 1

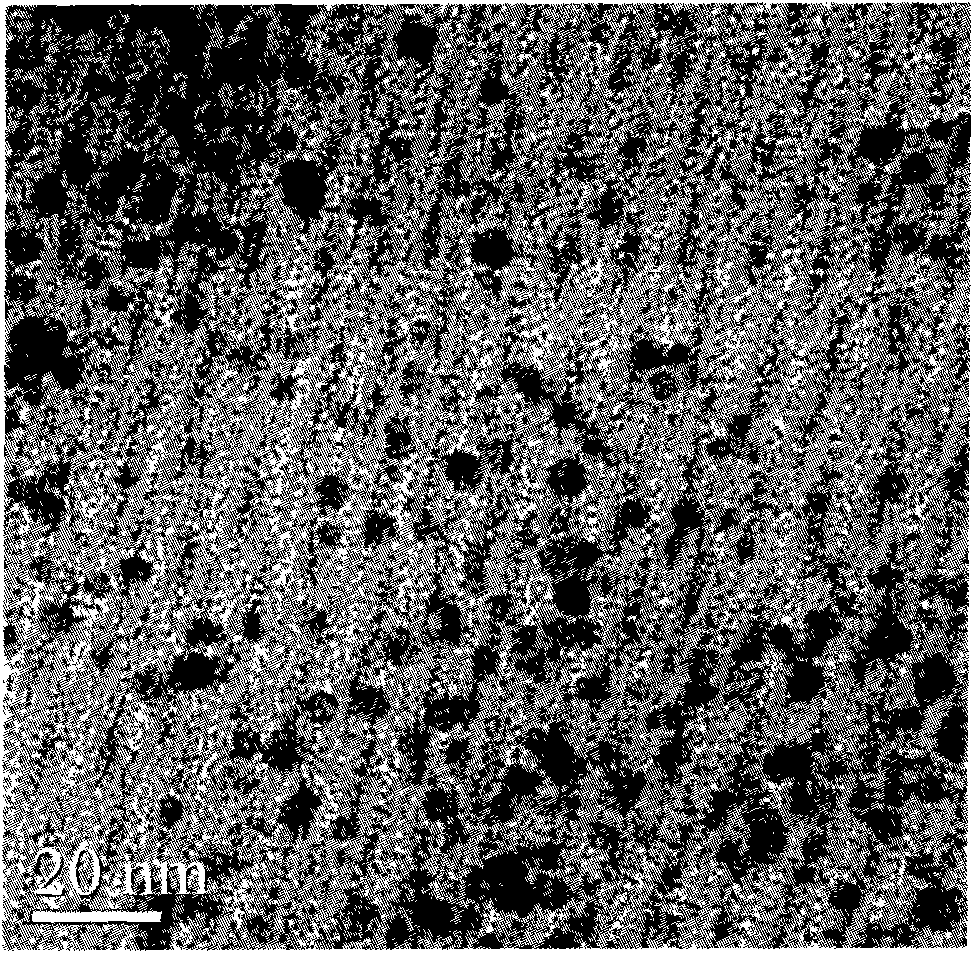

[0024] Configure 30 grams of mass concentration in the flask to be 0.5% nanocellulose suspension prepared from absorbent cotton, add 5 milliliters of 0.1mol / L HAuCl 4 solution, the temperature of the water bath was raised to 60° C. to keep warm, condensed and refluxed, and magnetically stirred. After 60 minutes, 1 mL of hydrazine hydrate was added dropwise, aged for 2 hours, and the gold nanoparticles were centrifuged, and the product was washed 6 times with water to obtain water-dispersed gold nanoparticles. Such as figure 1 As shown, the particle size is 5 ± 2nm. It can be seen from the figure that the dispersibility is very good, and there is no obvious settlement after preparing a 1% wt dispersion in water and standing for a month.

Embodiment 2

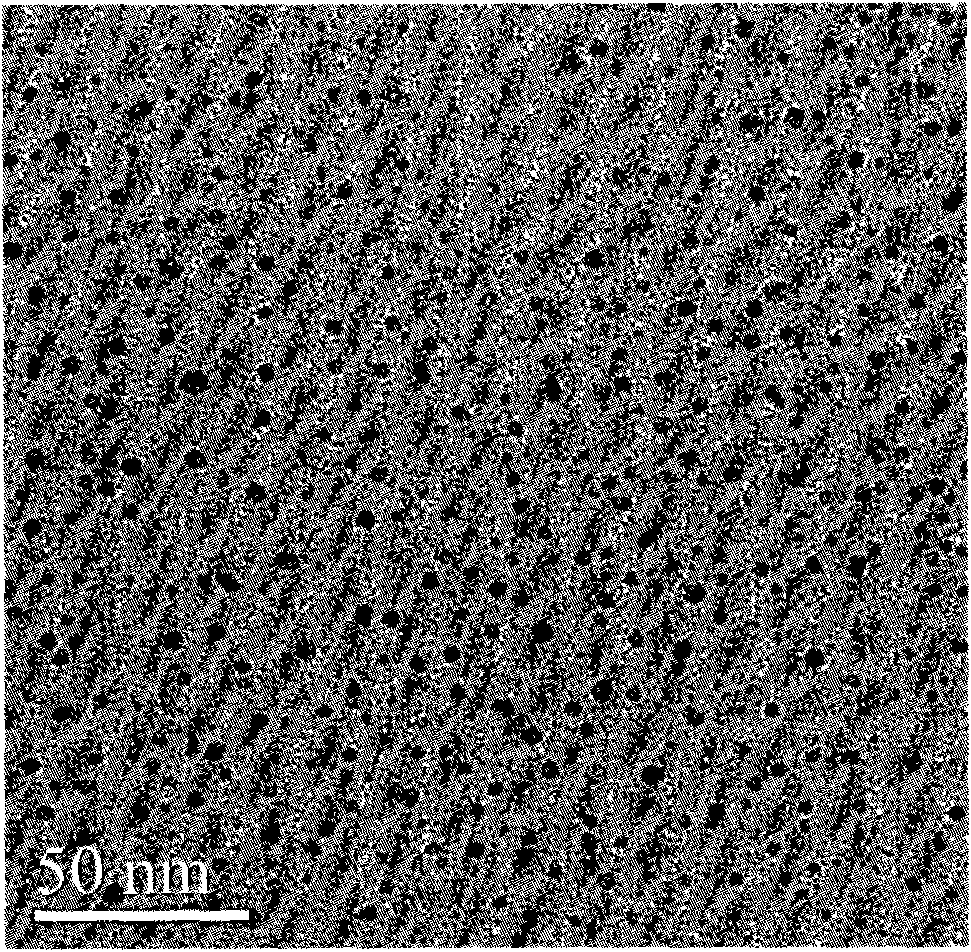

[0026] Configure 600 grams of 1%wt nanocellulose suspension prepared from flax in the flask, add 40 milliliters of 0.5mol / L Ni(NO 3 ) 3 solution, adjust the solution to weak alkalinity with NaOH, heat the water bath to 90°C, condense and reflux, and continue mechanical stirring. After 30 minutes, add 30mL of hydrazine hydrate dropwise, mature for 4 hours, centrifuge to separate nickel nanoparticles, and wash the product 3 times. To obtain water-dispersible nickel nanoparticles, such as figure 2 As shown, the particle size is below 5nm, and it can be seen from the figure that the dispersibility is very good, and there is no obvious settlement after preparing a 1%wt dispersion in water and standing for a month.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com