Graphene/nickel oxide laminated-structure composite film and preparation method thereof

A nickel oxide layer and composite film technology, applied in nickel oxide/nickel hydroxide, layered products, etc., can solve the problems of complex preparation technology, and achieve the effects of easy process amplification, good electrical conductivity, strength, and adjustable scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of graphene oxide solution refers to literature (Chen C M, Yang Q H, Yang Y G, et al. Self-assembled free-standing graphite oxide membrane [J]. Advanced Materials, 21 (29), 3007, 2009.). Take 50 mg of graphite oxide, add 100 mL of water, and ultrasonicate for 2 hours with an ultrasonic power of 300 W to obtain a well-dispersed graphene oxide solution.

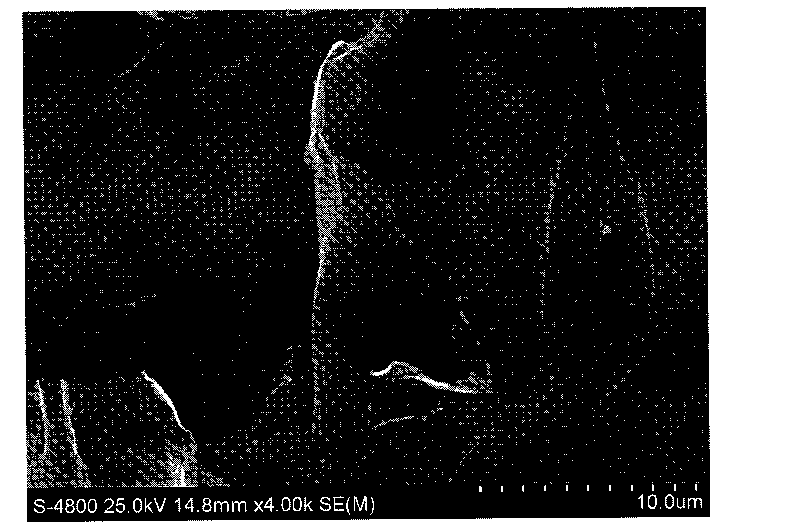

[0021] Measure 50mL of the graphene oxide solution prepared above and 10mL of 0.01mol / L nickel nitrate into a 100mL beaker, ultrasonically disperse in an ice-water bath for 1h, and the ultrasonic power is 240W, to obtain a well-dispersed graphene oxide / nickel nitrate aqueous solution. Then the solution was moved into a vacuum drying oven at 80° C., and kept for 3 days to obtain a graphene oxide / nickel nitrate composite film. in the description of the attached figure 1 For this reason, the macroscopic picture of the graphene oxide / nickel nitrate composite film, it can be seen from the figure that the film...

Embodiment 2

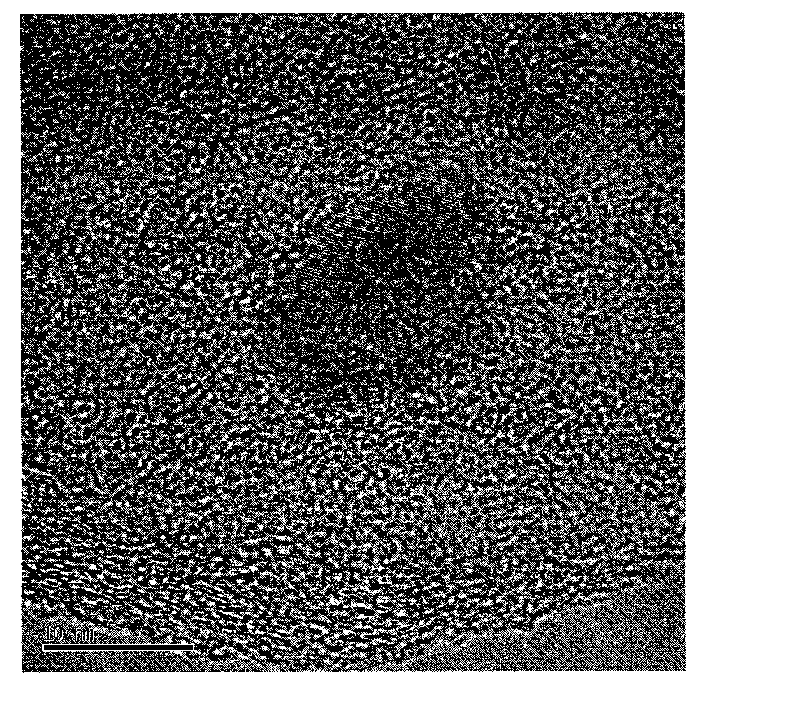

[0024] Put the graphene oxide / nickel nitrate composite film prepared in Example 1 into a high-temperature vacuum furnace, and perform heat treatment at 600°C under a protective atmosphere. The temperature was kept at ℃ for 3 hours, and finally a graphene / nickel oxide layered structure composite film was obtained. in the description of the attached image 3 For this reason, the TEM picture of the graphene / nickel oxide layered structure composite film can be seen from the figure that there are obvious metal stripes, which are identified as nickel oxide particles with a diameter of 15nm, and the number of layers of graphene is below 10 layers. The thickness of the film is 35nm, the specific capacitance reaches 600F / g, and the particle size of nickel oxide is 15nm.

Embodiment 3

[0026] Put the graphene oxide / nickel nitrate composite film prepared in Example 1 into a high-temperature vacuum furnace, and perform heat treatment at 700°C under a protective atmosphere. The temperature was kept at ℃ for 3 hours, and finally a graphene / nickel oxide layered structure composite film was obtained. The thickness of the film is 60nm, the specific capacitance reaches 360F / g, and the particle size of nickel oxide is 1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com