Photoelectrochemical mechanical polishing processing method of semiconductor wafer

A mechanical polishing and photoelectrochemical technology, applied in semiconductor/solid-state device manufacturing, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of long processing time, high cost, low polishing removal rate, etc. The processing device is simple, the polishing removal rate is fast, and the processing method is easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

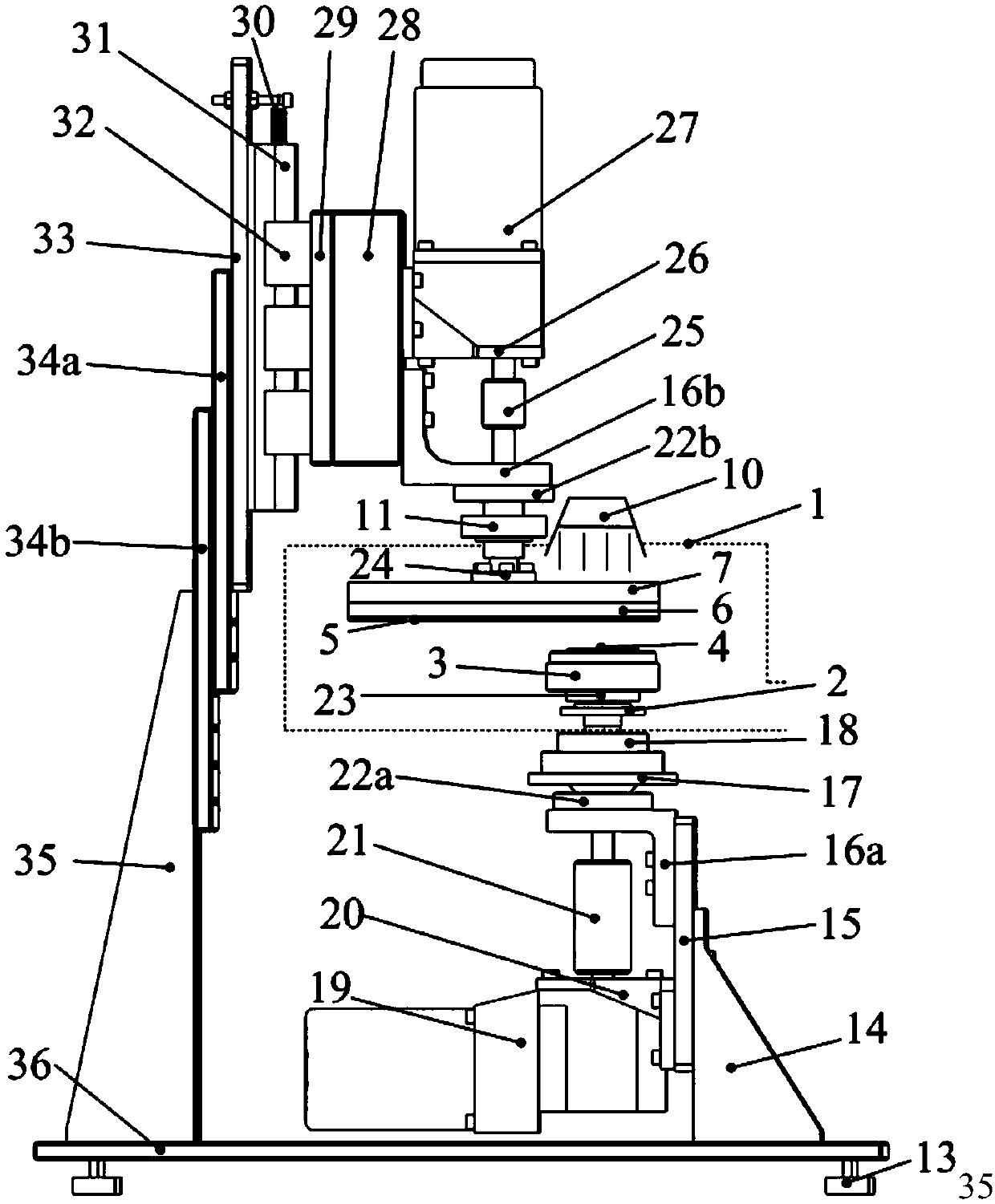

[0057] The present invention will be further described below in conjunction with accompanying drawing.

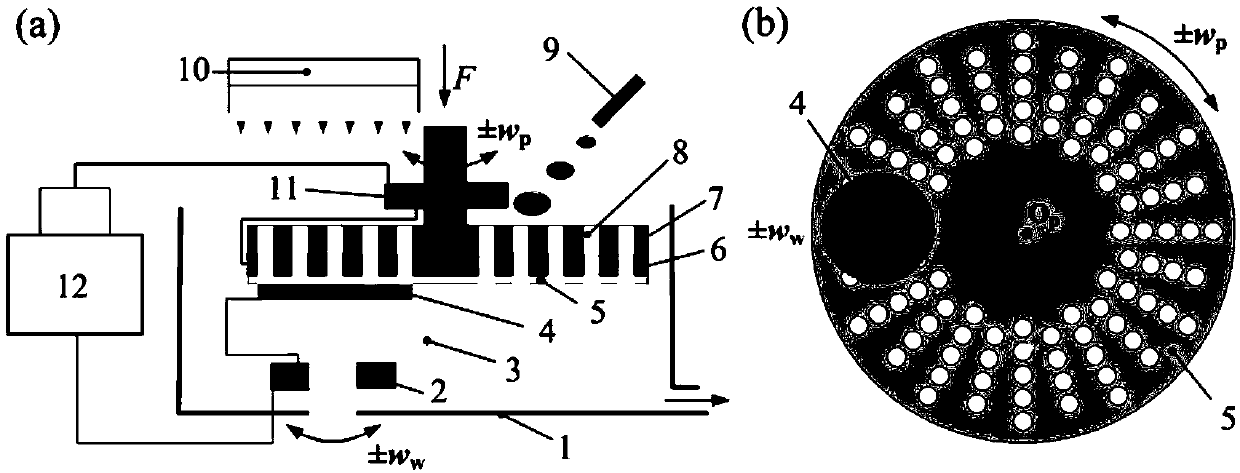

[0058] (1) Fix the wafer on the polishing head, and after being driven, the wafer rotates axially with the polishing head; the wafer is connected to the metal part of the polishing head through conductive glue, and the polishing head is connected to the inner ring wire of the conductive slip ring, and then connected to the conductive The outer ring of the slip ring is connected to form a passage;

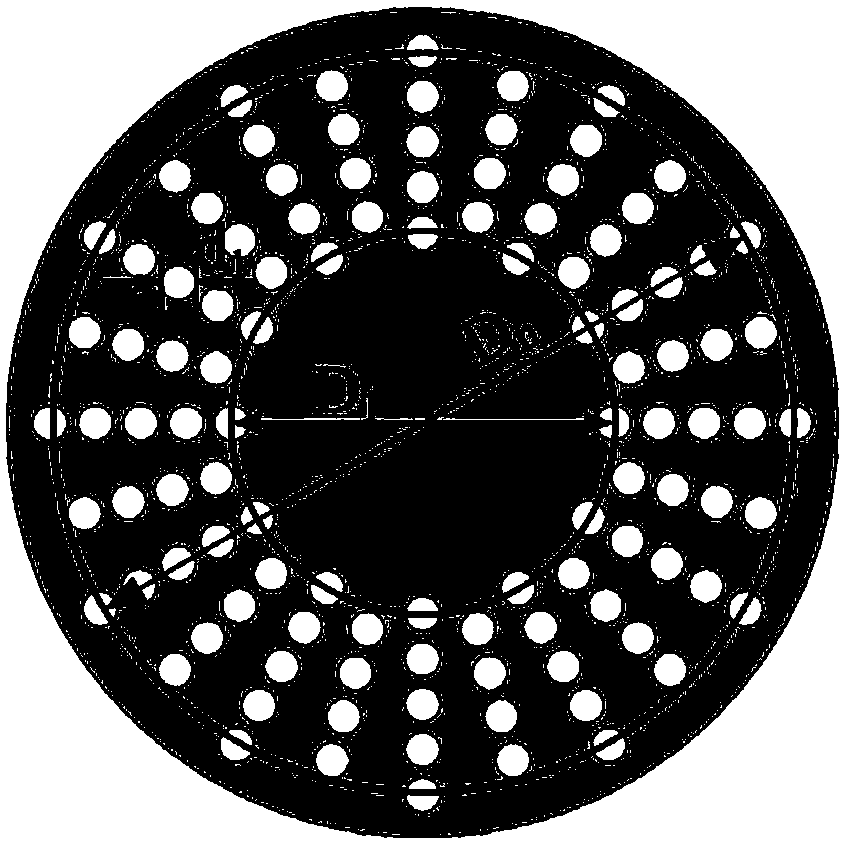

[0059] (2) Bond the polishing pad to the counter electrode disc, and the counter electrode disc is fixed on the polishing disc. After driving, the polishing pad contacts the surface of the wafer and generates relative movement. The counter electrode disc can be connected to the inner ring wire of the conductive slip ring. Connect, and then connect with the outer ring wire to form a path;

[0060] (3) Through holes are processed on the counter electrode disc and the polishing dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com