Low-pressure methanol synthesizing process

A methanol synthesis, low pressure technology, applied in the preparation of hydroxyl compounds, the preparation of organic compounds, the separation/purification of hydroxyl compounds, etc., can solve the problem of increasing heat exchange area, heat exchanger specifications and engineering investment, lack of reaction load adjustment means , unfavorable to large-scale reactors, etc., to achieve the effect of reducing installation height and technical requirements, efficient and reasonable utilization of reaction heat, and fast and efficient heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

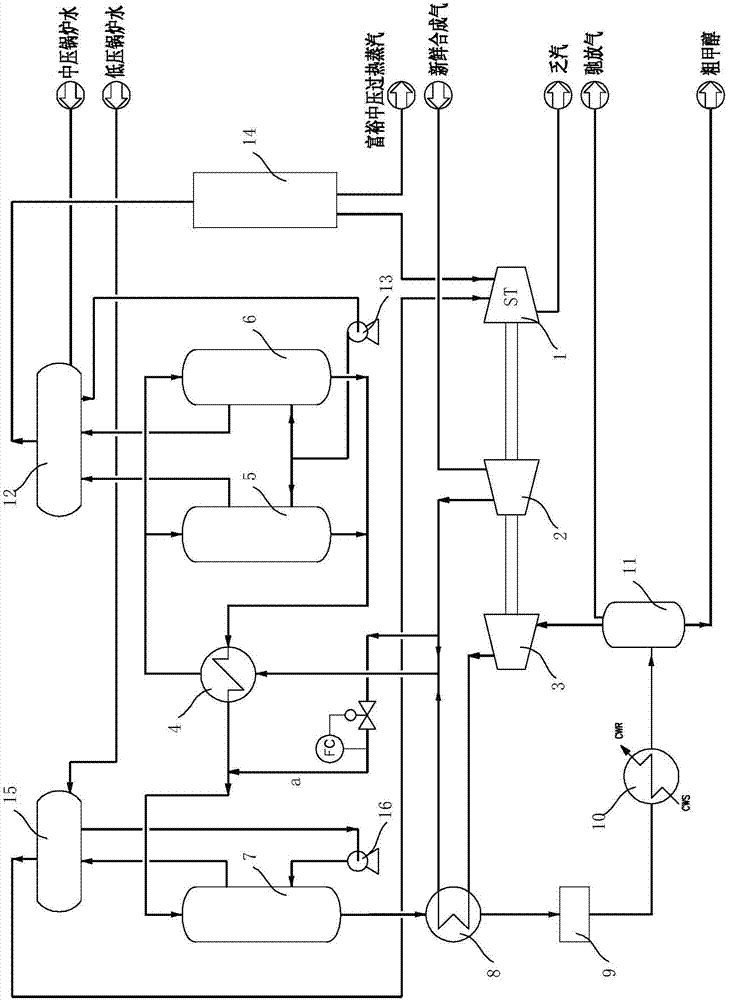

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] Such as figure 1 As shown, the low-pressure methanol synthesis process of the present embodiment comprises the following steps:

[0029] Fresh syngas from upstream processes (mainly H 2 , CO, CO 2 , molar ratio: (H 2 -CO 2 ) / (CO+CO 2 )=2.05~2.15) pressurized to 6.0~10.0MPaG by synthesis gas compressor 2, mixed with circulating gas preheated by synthesis gas thermostat 8, and then preheated to 210~250°C by gas-gas heat exchanger 4 , into two parallel first-stage reactors 5 and 6, under the action of a copper-based methanol synthesis catalyst, methanol synthesis reaction is carried out; the temperature of the high-temperature first-stage reaction gas at the outlets of the first-stage reactors 5 and 6 is 250-280° C. The gas-gas heat exchanger 4 is cooled to 200-220°C, and enters the secondary reactor 7 to continue the methanol synthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com