Rail vehicle traction inverter system and method for integrated energy storage device charging and discharging control

A traction inverter system, charge and discharge control technology, applied in the field of rail vehicle traction inverter system, can solve the problems of high comprehensive cost of equipment, low real-time performance and reliability, complex system, etc., to improve energy utilization rate, improve Effect of controlling real-time performance and reliability, simplifying hardware circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

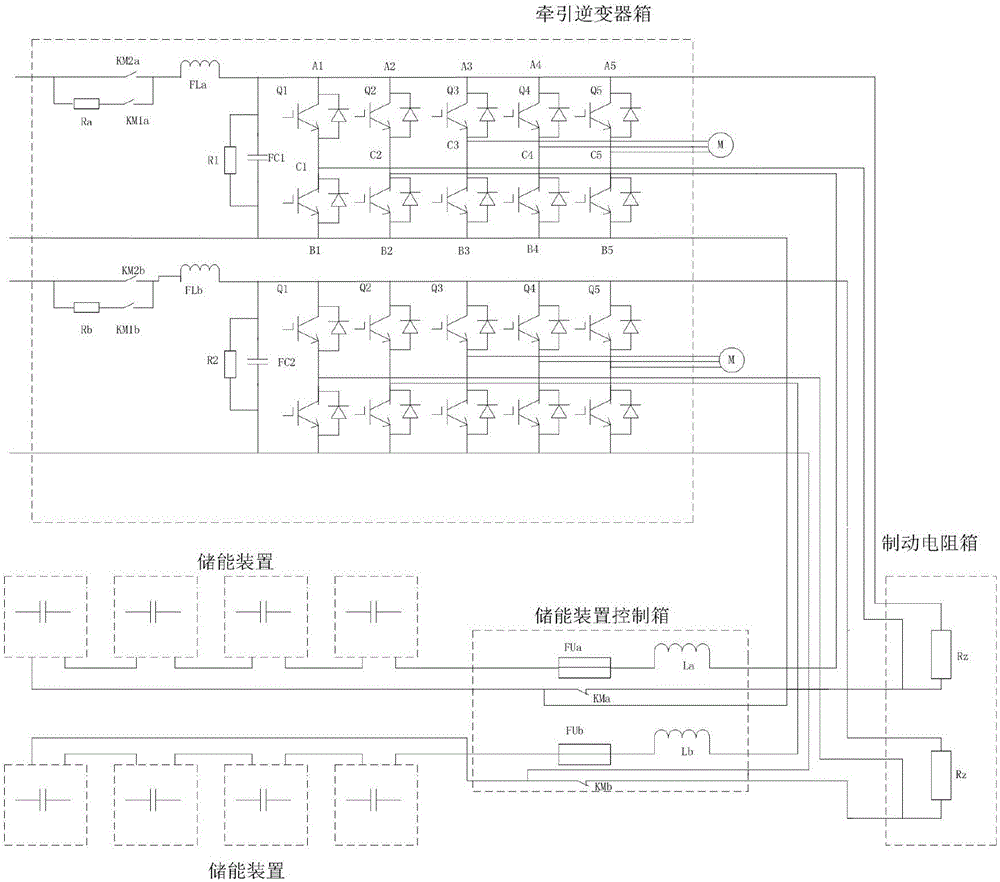

[0033] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

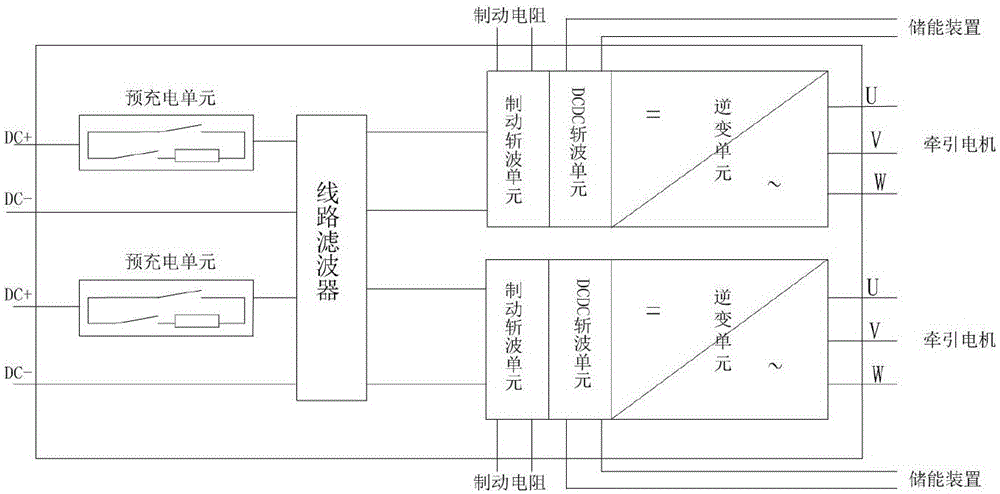

[0034] Such as figure 1 As shown, the rail vehicle traction inverter system integrated with the charge and discharge control of the energy storage device includes a pre-charging unit, a line filter unit, a current and voltage detection unit, two sets of traction inverter units and a control unit.

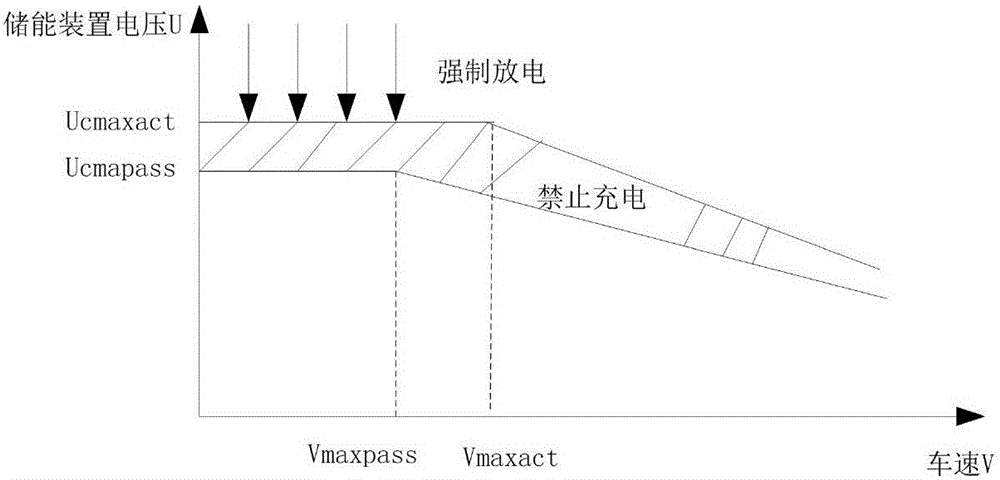

[0035] There are two groups of pre-charging units and one group of line filtering units; the DC line network side is connected to the input end of a group of line filtering units through two groups of pre-charging units respectively; each group of traction inverter units includes an integrated chopper module and an inverter module, the chopper module includes a brake chopper unit and a DCDC chopper unit, the brake chopper unit is connected to the output end of the line filter unit, the brake resistor and the DCDC chopper unit respectively; the DCDC ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com