Method for extracting, separating and purifying formononetin and calycosin from Astragalus mongholicus waste residue

A technology of vervasoflavone and formononetin, applied in the field of astragalus isoflavones, can solve the problems of wasting astragalus resources and the like, and achieve the effects of good application value, short extraction period and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

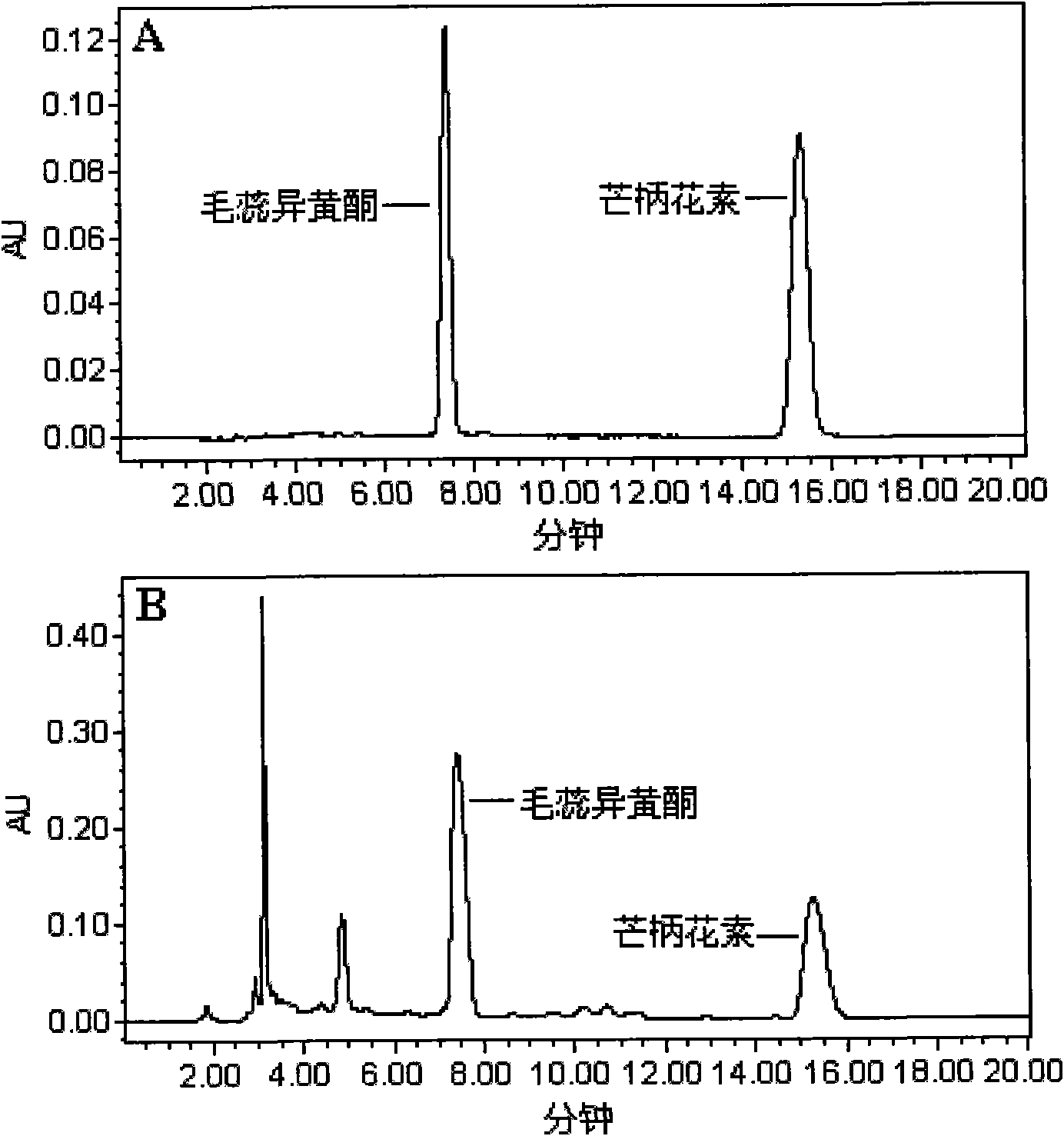

[0028] Accurately weigh 1000 g of astragalus waste residue, dissolve 0.1% solid content of mixed enzymes (cellulase, pectinase, protease, xylanase) in 10 times the volume of warm water, and continuously homogenize and extract 3 times, each time for 2 minutes . Put the homogenate into a constant temperature shaker at 30°C for constant temperature enzymolysis for 12 hours. After the enzymolysis solution is suction-filtered, the filter residue is extracted by negative pressure cavitation with 70% ethanol solution, the pressure is 0.05Mpa, and the solid-liquid ratio is 1:10 (g: mL), extracted at room temperature 3 times, 45min each time, combined the enzymolysis solution after suction filtration and the negative pressure cavitation extraction solution, concentrated under reduced pressure to dryness, dissolved in water, and extracted 3 times with an equal volume of ethyl acetate as the extraction solvent. times, and concentrated to dryness under reduced pressure to obtain a solid. ...

Embodiment 2

[0030]Accurately weigh 1000 g of astragalus waste residue, dissolve 0.3% mixed enzymes (hemicellulose, β-glucosidase, laccase, amylase) in 15 times the volume of warm water, and extract 5 times with continuous homogenate, each time 1min. Put the homogenate in a constant temperature shaker at 30°C for constant temperature enzymolysis for 24 hours. After suction filtration of the enzymolysis solution, add 90% ethanol solution to the filter residue for negative pressure cavitation extraction, the pressure is 0.06Mpa, and the solid-liquid ratio is 1:15 (g: mL), extract at room temperature 5 times, each time for 30min, combine the enzymolysis solution after suction filtration and the negative pressure cavitation extraction solution, concentrate under reduced pressure to dryness, dissolve in water, and mix with 1:1.5 (v / v) ethyl acetate The ester was used as the extraction solvent to extract 5 times, and concentrated to dryness under reduced pressure to obtain a solid. After the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com