Preparation method of gangue base mine cemented filling material

A technology for cementing filling materials and coal gangue, applied in the field of mine filling materials, can solve the problems of less than 20% utilization rate of coal gangue, restricting the forward development of coal mine filling, unstable transportation performance, etc. The effect of previous development and broadening of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

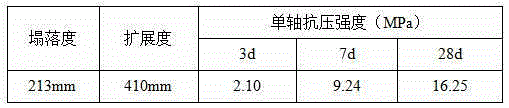

Embodiment 1

[0035] (1) First, crush and screen large pieces of coal gangue with a jaw crusher, and control the particle size of coal gangue within the range of 0 to 5mm.

[0036] The effective chemical composition of the gangue is: SiO 2 : 35.46%, Al 2 o 3 : 16.11%

[0037] (2) Accurately weigh 18kg of 0-5mm coal gangue and grind it in a ball mill for 45 minutes, and then sieve it with 200-mesh and 300-mesh standard sieves to obtain coal gangue powder with a particle size of less than 300 mesh for use.

[0038] (3) Put all 18kg of coal gangue powder in step (2) into an industrial furnace, heat up to 750°C for calcination, and calcine at a constant temperature of 750°C for 2 hours.

[0039] (4) The calcined coal gangue in step (3) is taken out and rapidly cooled for later use.

[0040] (5) Add 1.62kg of Al to the gangue powder in step (4) 2 (SO 4 ) 3 , 0.54kg of NaOH, 0.84kg of CaSO 4 2H 2 O Powdered chemical reagents of analytical grade, and pre-mixed for 30s, so that the compone...

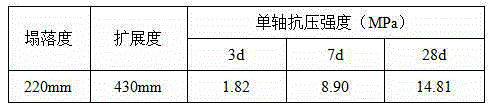

Embodiment 2

[0046] (1) First, crush and screen large pieces of coal gangue with a jaw crusher, and control the particle size of coal gangue within the range of 0 to 5mm.

[0047] The effective chemical composition of the gangue is: SiO 2 : 50.33%, Al 2 o 3 : 23.46%

[0048] (2) Accurately weigh 15kg of 0-5mm coal gangue and grind it in a ball mill for 60 minutes, and then sieve it with 200-mesh and 300-mesh standard sieves to obtain coal gangue powder with a particle size of less than 300 mesh for use.

[0049](3) Put all 15kg of coal gangue powder in step (2) into an industrial furnace, heat up to 700°C for calcination, and calcine at a constant temperature of 700°C for 2.5 hours.

[0050] (4) The calcined coal gangue in step (3) is taken out and rapidly cooled for later use.

[0051] (5) Add 1.20kg of Al to the gangue powder in step (4) 2 (SO 4 ) 3 , 0.60kg of NaOH, 0.45kg of CaSO 4 2H 2 O Powdered chemical reagents of analytical grade, and pre-mixed for 30s, so that the compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com