A continuous reaction device and a method for synthesizing furfuryl mercaptan using the device

A reaction device, a technology for furfuryl mercaptan, which is applied in feeding devices, chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, etc., can solve the problems of difficult control of reaction conditions, high cost, low yield, etc. , to achieve the effect of easy control of reaction conditions, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

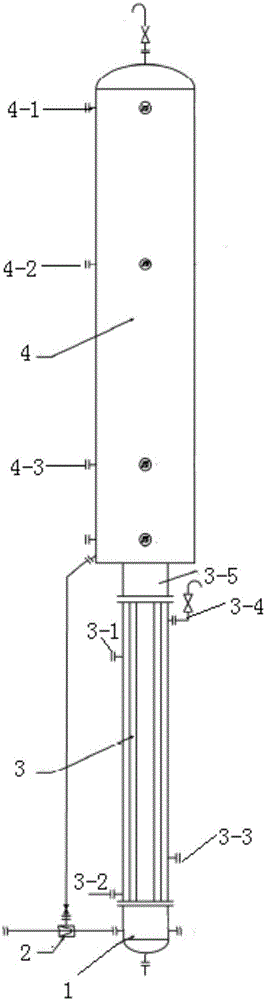

[0059] The continuous reaction device of the present invention can be applied to various product types suitable for continuous reaction. This embodiment provides a continuous reaction device for preparing furfuryl mercaptan, such as figure 1 Shown, comprise mixed-flow reactor and flat-flow insulation reactor 4; Wherein:

[0060] The mixed-flow reactor includes a tube-and-tube reactor 3 , a Venturi mixer 2 and a lower head 1 connected to the bottom of the tube-and-tube reactor 3 .

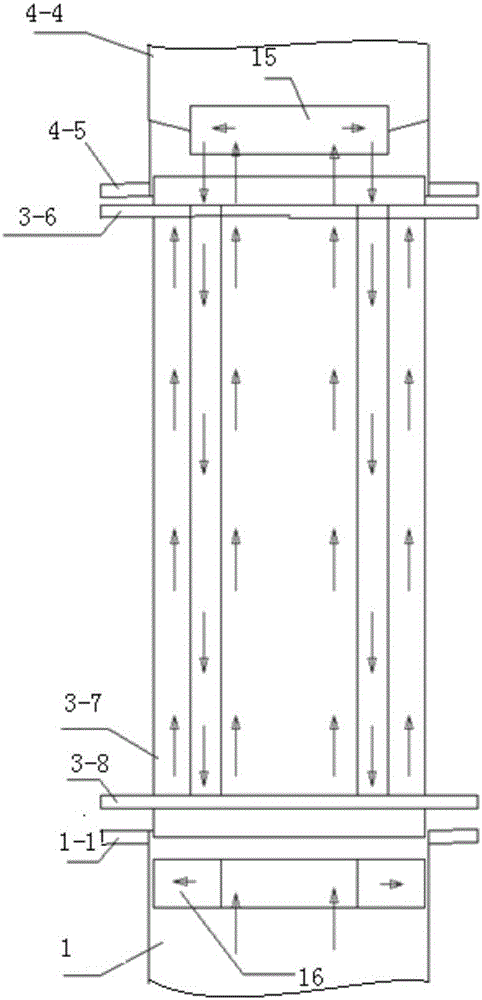

[0061] The inside of the tubular reactor 3 includes several vertical pipes for material reaction, and there are accommodation (or communication) between the vertical pipes and between the vertical pipes and the wall of the tubular reactor. ) gaps for steam and / or cooling water; the aspect ratio of the vertical pipe (the ratio of length to diameter of the pipe) is 50:1.

[0062] Several parts for deflecting materials are arranged on the inner wall of the vertical pipe; the parts for deflecting mate...

Embodiment 2

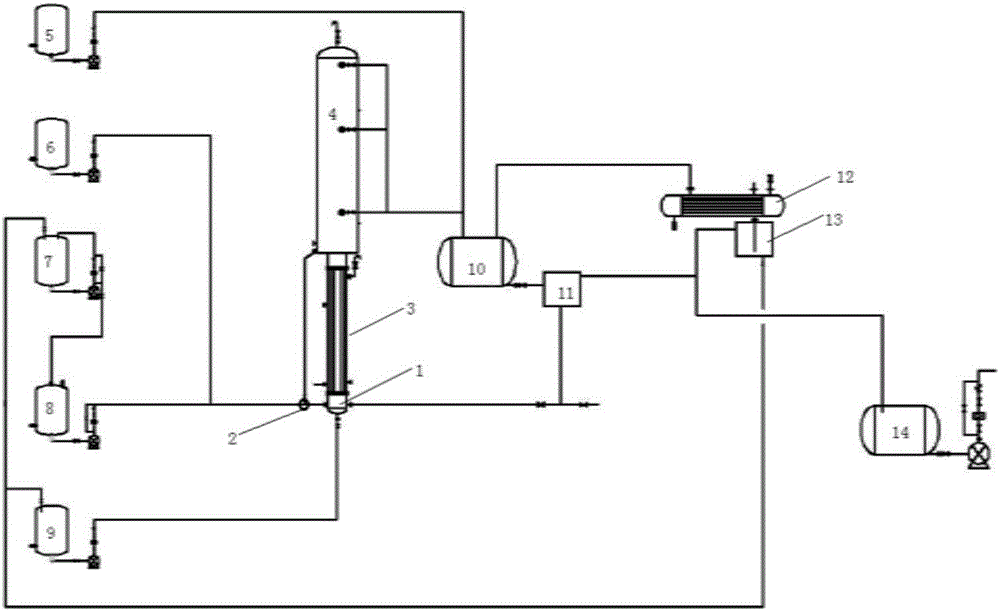

[0076] A continuous reaction system for the production of furfuryl mercaptan, such as figure 2 Shown, at least comprise the continuous reaction device described in embodiment 1 (such as figure 1 shown), furfuryl alcohol storage tank 6, thiourea solution storage tank 7, thiourea solution storage tank 8, hydrochloric acid storage tank 9, sodium hydroxide aqueous solution storage tank 5, steam distiller 10, condenser 12, the first minute Stratifier 11, second stratifier 13 and crude product storage tank 14;

[0077] The furfuryl alcohol storage tank 6, the thiourea solution storage tank 7, the thiourea solution storage tank 8, and the hydrochloric acid storage tank 9 are connected to the Venturi mixer 2 in the continuous reaction device by a pump and a pipeline;

[0078] The outlet of the flat-flow heat preservation reactor 4 in the continuous reaction device is connected to the liquid inlet of the steam distiller 10 through the aqueous sodium hydroxide storage tank 5, and the ...

Embodiment 3

[0082] A kind of method adopting the continuous reaction device in embodiment 1 to synthesize furfuryl mercaptan may further comprise the steps:

[0083] (1) Prepare raw materials: mass concentration is 30% hydrochloric acid solution, furfuryl alcohol (content > 99%), thiourea by mass ratio: water=42:100 is mixed with saturated thiourea aqueous solution, mass concentration is 20% sodium hydroxide solution.

[0084] (2) Enter the hydrochloric acid solution, furfuryl alcohol and thiourea aqueous solution into the vertical pipeline in the mixed flow reactor according to the set ratio, and the flow ratio of the hydrochloric acid solution, furfuryl alcohol and thiourea aqueous solution entering the described flow mixer is 0.5 :0.5:(0.2~0.5), through steam heating and / or cooling of cooling water, hydrochloric acid, furfuryl alcohol and thiourea reach the required reaction temperature of 54~56°C, and part of hydrochloric acid, furfuryl alcohol and thiourea react to form furfuryl Iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com