Filter cleaning system and method

A cleaning system and filter technology, applied to chemical instruments and methods, membrane filters, fixed filter elements, etc., can solve the problems of less effective cleaning, damage, and excessive cleaning of filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

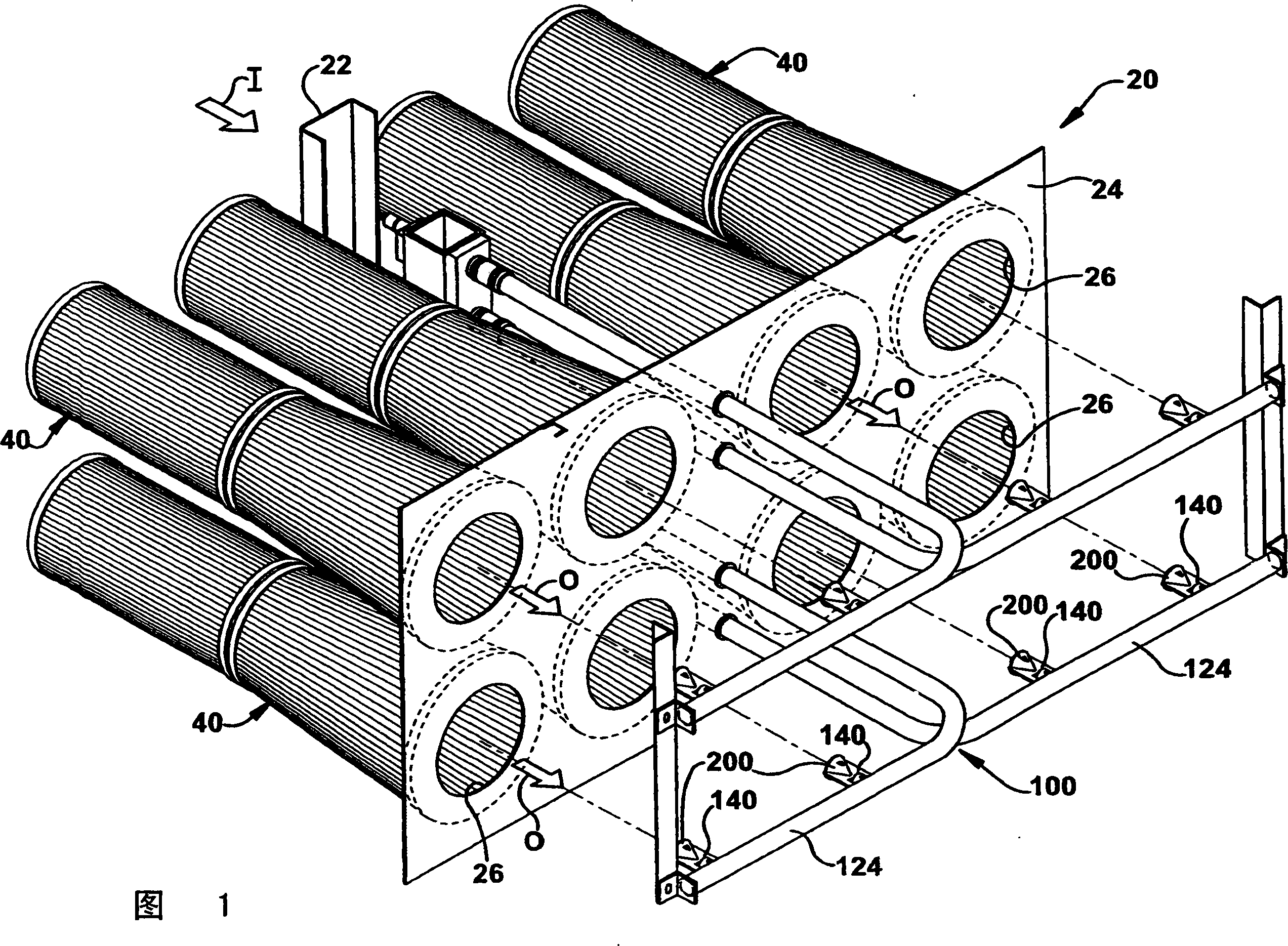

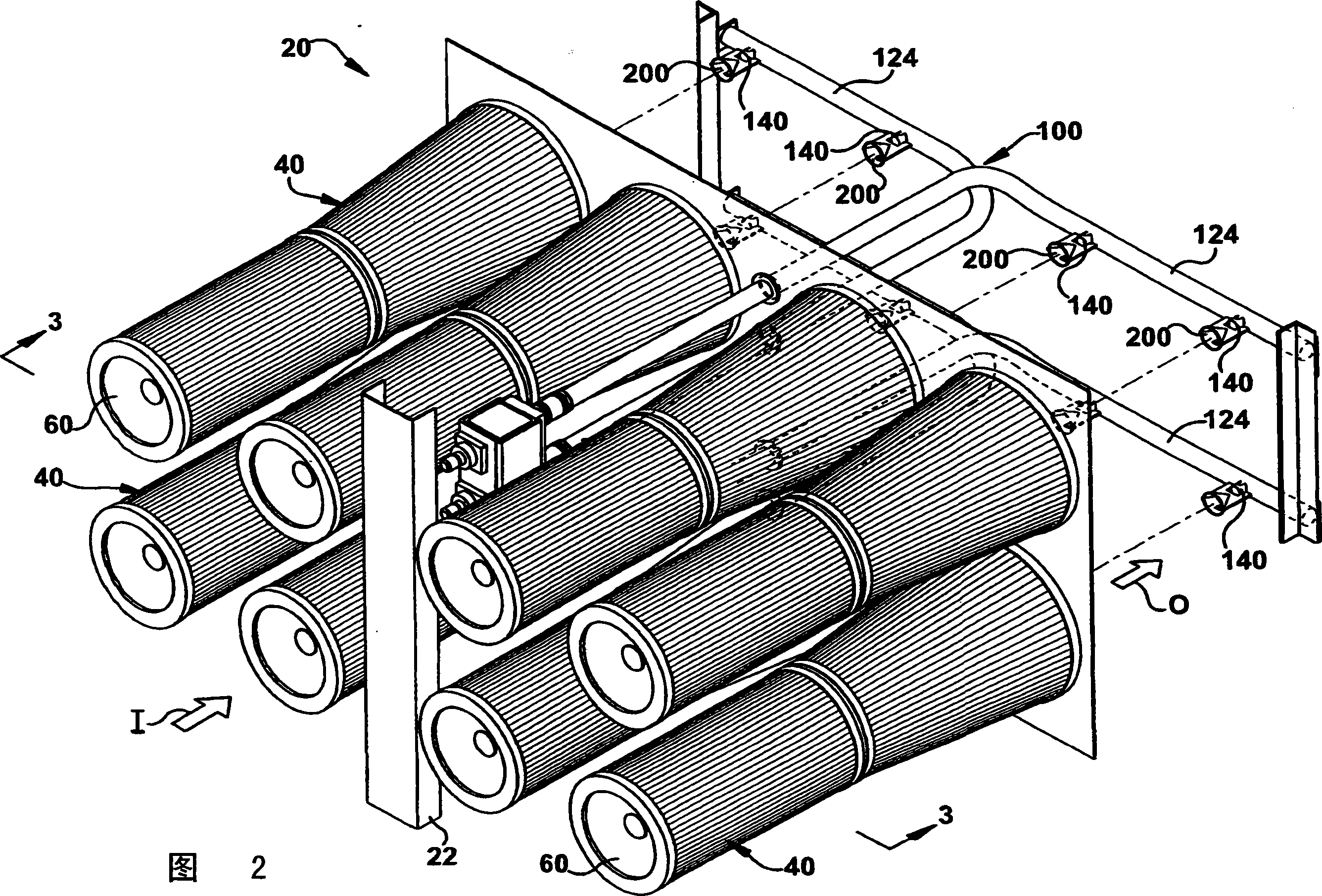

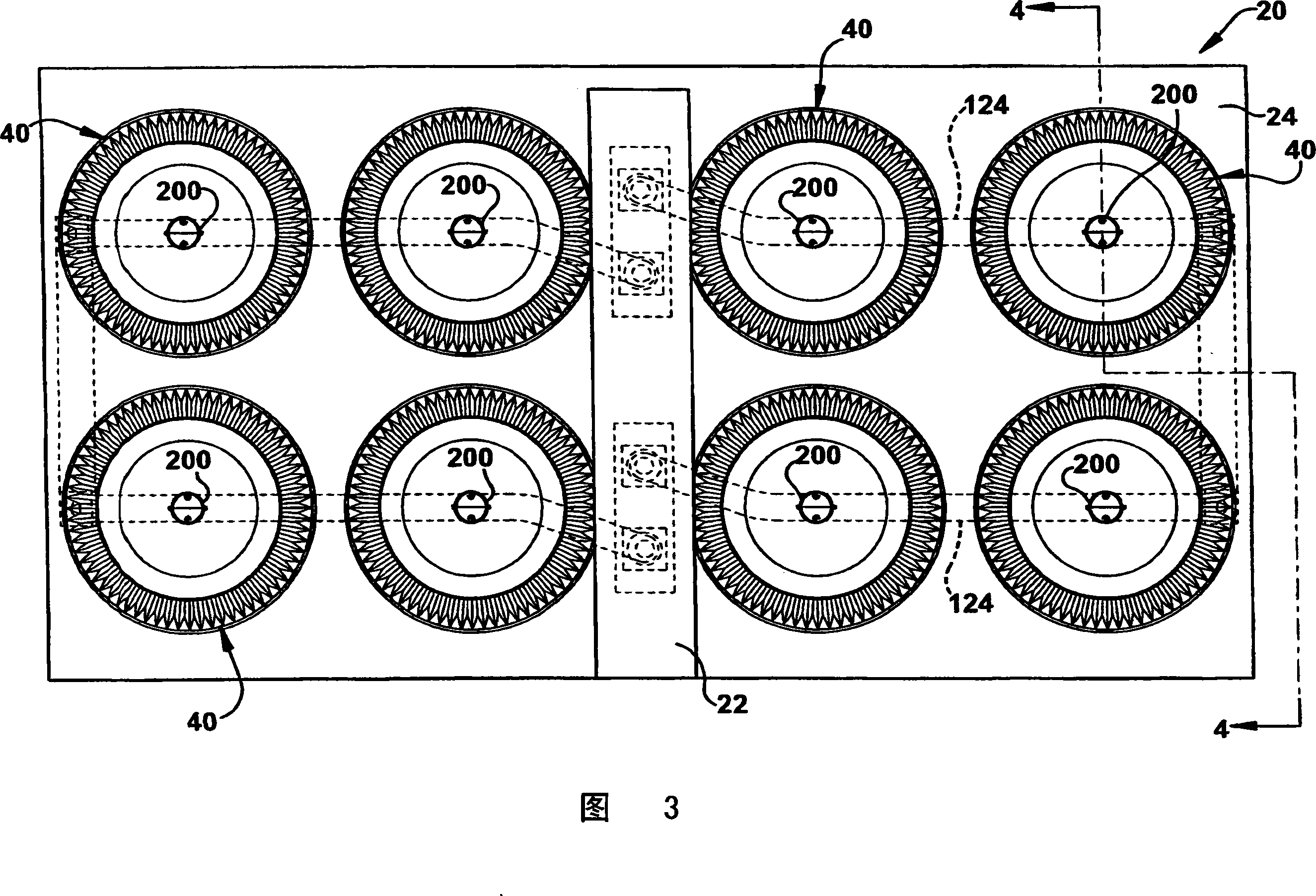

[0056] Filter system 20

[0057] Rack 22

[0058] Tube sheet 24

[0059] Opening 26

[0060] Filter assembly 40

[0061] First filter element 42

[0062] Second filter element 44

[0063] Upstream 46

[0064] Downstream side 48

[0065] (Of filter 40) proximal part 50

[0066] Filter 40) distal part 52

[0067] Removable end cap 60

[0068] Air chamber 66

[0069] Pulse jet cleaning system 100

[0070] Pulse valve 120

[0071] Manifold 122

[0072] Nozzle 124

[0073] Nozzle 140

[0074] Inlet or first end section 142

[0075] Outlet or second end section 144

[0076] Opening 160

[0077] Aspirator 180

[0078] Diffuser 200

[0079] Installation part 202

[0080] Main part 204

[0081] Exhaust notch 222

[0082] Opening 224

[0083] Diffuser (second embodiment) 300

[0084] Respective installation part 302

[0085] Installation part 302

[0086] Main part 304

[0087] Non-deflecting surface 306

[0088] Deflection surface 308

[0089] Diffuser (third embodiment) 400

[0090] Install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com