A method for reducing the content of soluble impurities in wastewater by utilizing a gas-liquid impact mixing reaction system

A technology of reaction system and impurity content, applied in chemical instruments and methods, water/sewage treatment, biological water/sewage treatment, etc., to achieve the effects of easy popularization and application, fast update speed, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

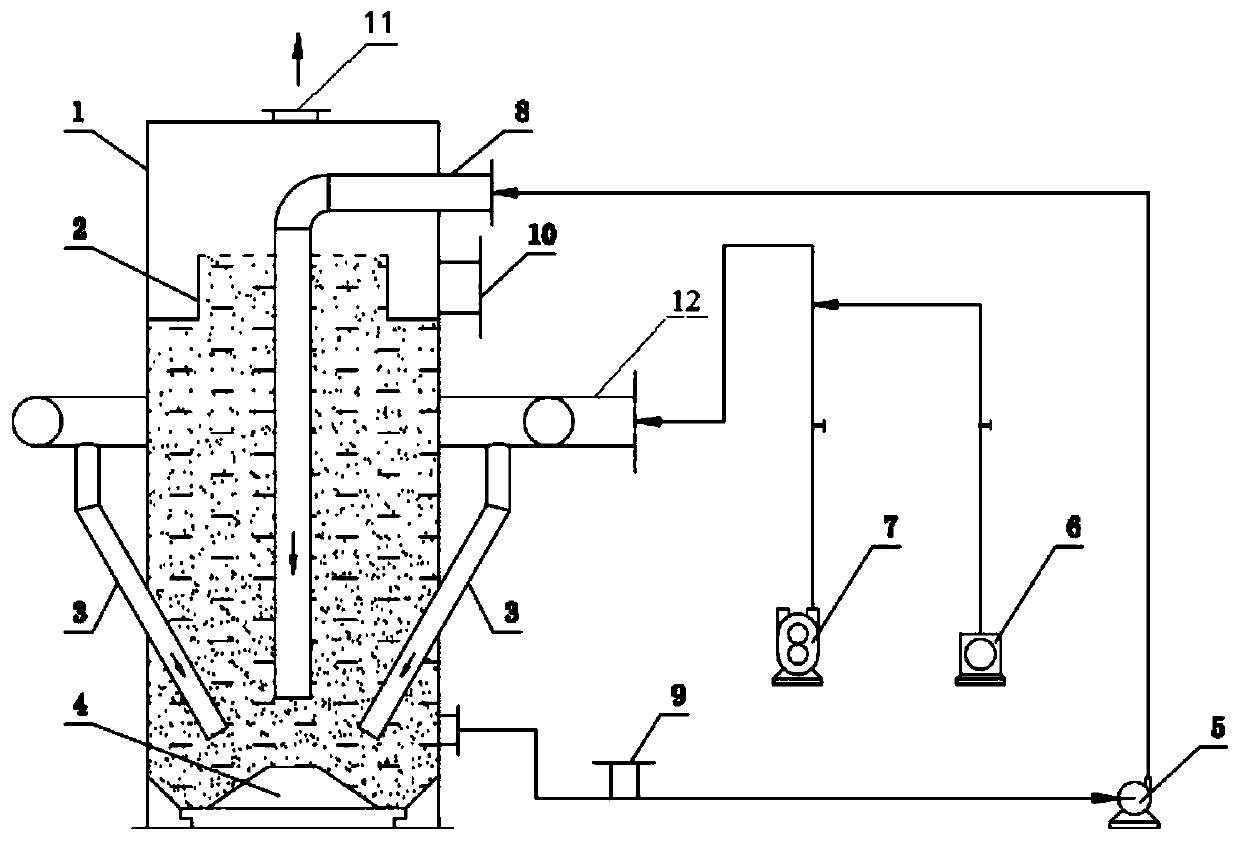

Image

Examples

Embodiment 1

[0032] This embodiment adopts a gas-liquid impact mixing reaction system, using air as the main raw material, specifically including the following steps:

[0033] (1) Introduce the waste water to be treated with a COD content of 1100mg / L into the circulation pipeline, turn on the circulating water pump, and make the waste water to be treated (flow rate about 10m 3 / h, the flow rate is about 2m / s) through the liquid impact tube and spray down into the circulating liquid storage tank, so that the cycle is carried out;

[0034] (2) Determine the required air volume of about 5000m 3 / h, the flow rate is about 12m / s;

[0035] (3) Turn on the blower and blow the clean natural air that has been dedusted into the circulating fluid storage tank from the blowing branch pipe;

[0036] (4) Adjust the air flow to 5000m 3 / h or so, so that the air and the waste water to be treated form a turbulent flow zone (foam reaction zone) within a certain range of the gas-liquid contact interface, ...

Embodiment 2

[0039] This embodiment adopts a gas-liquid impact mixing reaction system, with air and ozone as the main raw materials, specifically including the following steps:

[0040] (1) will S 2- The waste water to be treated with a content of 15mg / L is introduced into the circulation pipeline, and the circulating water pump is turned on to make the waste water to be treated (flow rate about 10m 3 / h, the flow rate is about 2m / s) is sprayed downwards into the circulating liquid storage tank through the liquid impact tube, and the sprayed wastewater returns to the circulating liquid storage tank after reaction, and the cycle is carried out like this;

[0041] (2) Determine the required air volume of about 5000m 3 / h, the flow rate is about 12m / s;

[0042] (3) Turn on the blower and the ozone generating device, and blow the air containing about 0.5% ozone into the circulating fluid storage tank from the blowing branch pipe;

[0043] (4) Adjust the air flow to 5000m 3 / h or so, so tha...

Embodiment 3

[0046] This embodiment adopts a gas-liquid impact mixing reaction system, using air as the main raw material, specifically including the following steps:

[0047] (1) Set the BOD content to 950mg / L and S 2- Content is 9.5mg / L waste water to be treated is introduced in the circulation pipe, and sodium hypochlorite (about 0.5%) is added in the water tank. Turn on the circulating water pump to make the waste water to be treated (flow rate about 10m 3 / h, the flow rate is about 2m / s) is sprayed downwards into the circulating liquid storage tank through the liquid impact tube, and the sprayed wastewater returns to the circulating liquid storage tank after reaction, and the cycle is carried out like this;

[0048] (2) Turn on the blower and blow the clean natural air that has been dedusted into the circulating fluid storage tank from the blowing branch pipe;

[0049] (3) Adjust the air flow to 5000m 3 / h, the flow rate is about 10m / s, so that the air and the waste water to be tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com