Blast-furnace tuyere with-air taking and conveying machine and taking and conveying method

A tuyere belt and blast furnace technology, applied in the field of machinery, can solve problems such as inability to measure temperature, and achieve the effect of filling technical gaps, reducing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

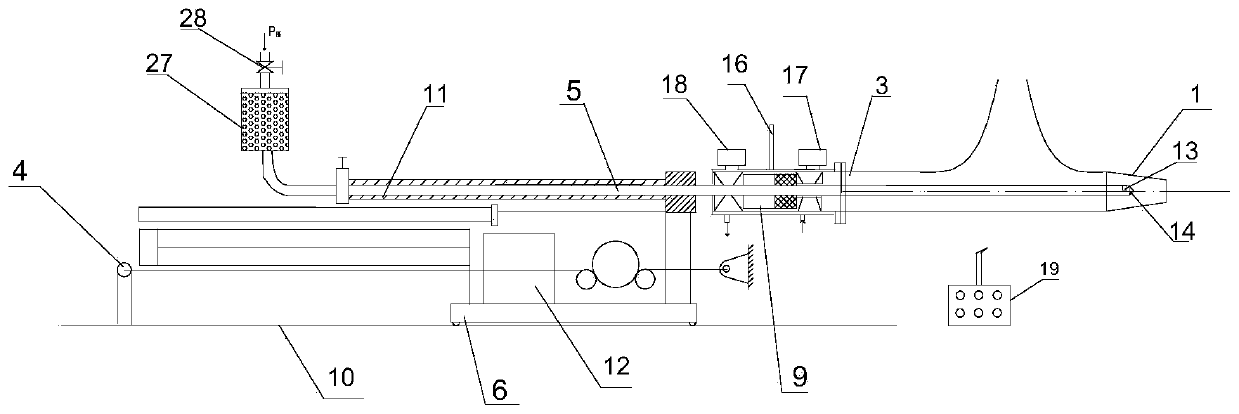

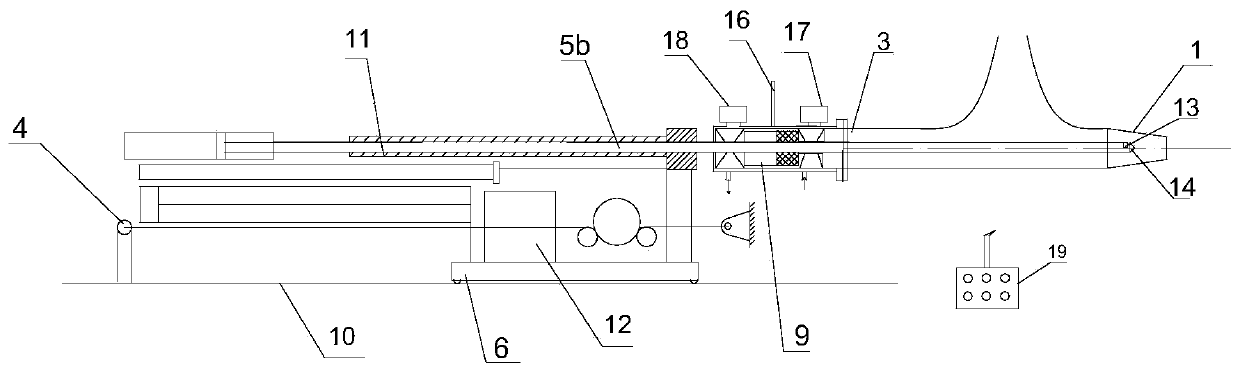

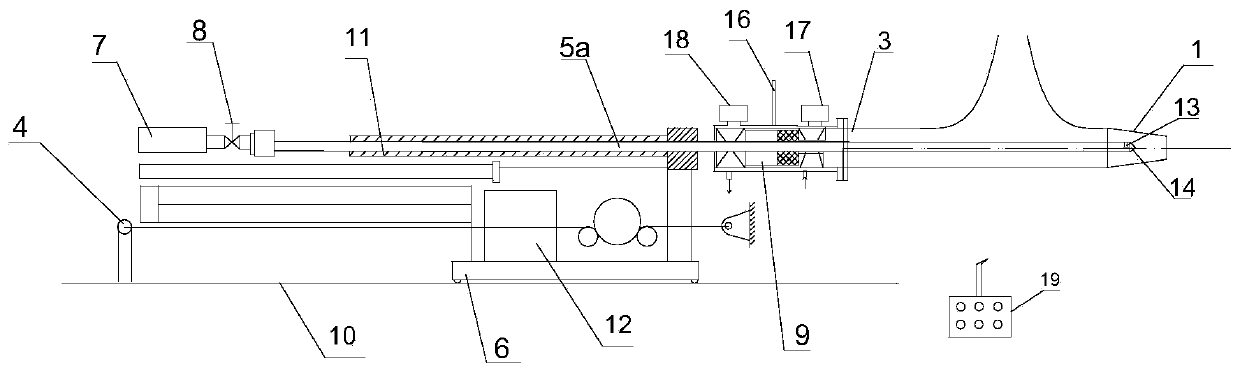

[0029] The structure of this embodiment is as image 3 , Figure 7-Figure 9 As shown, the blast furnace tuyeres take-up and delivery machine with wind, its structure includes a track 10, located in the track 10, the chassis traveling mechanism driven by a motor, placed at both ends of the track 10, connected by a chain to realize the front of the chassis traveling mechanism displacement , the rear chain seat 4, the frame and the wind sampling system arranged on the chassis walking mechanism, the chassis is a four-wheel chassis 6 or a crawler chassis 40, a control cabinet 12 with a temperature display is placed on the chassis, and the bottom of the frame is fixed on the chassis On the top of the frame, there is a guide rail mechanism 11 parallel to the track 10 for guiding the displacement of the wind sampling system. The wind sampling system includes a sampling tube 5a that can be displaced in the guide rail mechanism. The end of the sampling tube 5a passes through the control...

Embodiment 2

[0035] This embodiment is side sampling, except that the structure of the straight blowpipe is different, and the rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

[0036] The implementation scheme of blast furnace with air sampling at side tuyere is as follows: Figure 5 and Figure 6 As shown: there is a sampling port on the side of the sampling straight blow pipe 3, and the center line of the small sampling air outlet 1 and the center line of the sampling port on the side of the straight blow pipe 3 are on the same straight line, which is called the side sampling center line 20, and the side sampling center line 20 and the centerline 21 of the straight blowpipe form an included angle α, and the furnace controller 9 is installed on the side sampling port flange of the straight blowpipe 3 .

[0037] The center line of the motion track of the side blast furnace tuyere belt air feeder is consistent with the side sampling center line 20,...

Embodiment 3

[0039] The structure of this embodiment is as figure 1 , Figure 9 and Figure 10 As shown, the blast furnace tuyeres take-up and delivery machine with air has a structure including a track 10, which is located in the track 10, and the chassis traveling mechanism driven by a motor is placed at both ends of the track 10 and connected by a chain to realize the displacement of the chassis traveling mechanism. , the rear chain seat 4, the frame and the feeding system that are placed on the chassis walking mechanism, the chassis is a four-wheel chassis 6 or a crawler chassis 40, and the control cabinet 12 with a temperature display is placed on the chassis, and the bottom of the frame is fixed on the chassis. The top of the frame is provided with a guide rail mechanism 11 parallel to the track 10 for guiding the displacement of the air-feeding system. The air-feeding system includes a feed pipe 5 that can be displaced in the guide rail mechanism. The end of the feed pipe 5 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com