An all-fiber current transformer sensing device capable of active temperature compensation and a temperature compensation method

A technology of current transformer and temperature compensation, which is applied in the direction of measuring device, voltage/current isolation, measuring current/voltage, etc., can solve problems such as reduced service life, temperature drift of measurement accuracy, and difficult realization of algorithm structure, so as to avoid Reduced service life, strong resistance to temperature interference, and the effect of suppressing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

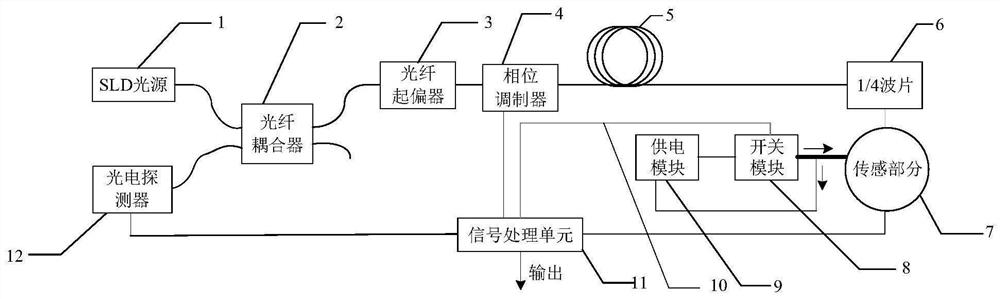

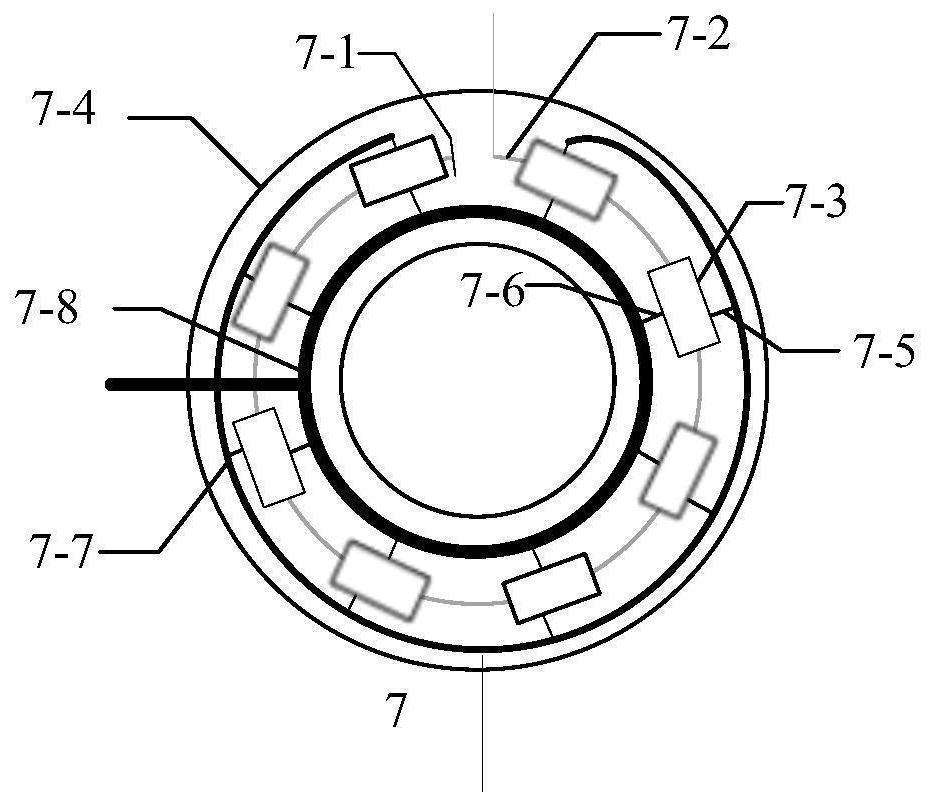

[0045] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 To illustrate this embodiment: the scheme adopted by the present invention is: an all-fiber-optic current transformer sensing device capable of active temperature compensation, including an SLD light source 1, an optical fiber coupler 2, an optical fiber polarizer 3, and a phase modulator 4 , polarization maintaining optical fiber delay line 5, 1 / 4 wave plate 6, sensing part 7, switch module 8, power supply module 9, switch signal line 10, signal processing unit 11 and photodetector 12; Described sensing part comprises reflection Mirror 7-1, sensing optical fiber 7-2, N identical and equiangularly distributed temperature self-balancing heating devices 7-3, aluminum alloy shell 7-4, temperature sensor signal line 7-5, heater power line 7- 6. Sensing signal integration bus 7-7 and power line integration bus 7-8; the temperature self-balancing heating device 7-3 also includes a tempe...

specific Embodiment approach 2

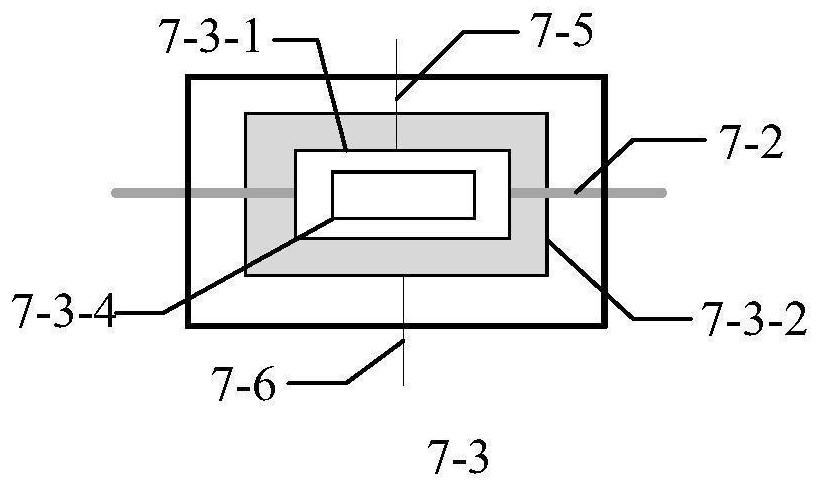

[0061] Specific implementation mode two: combination figure 1 , figure 2 , Figure 5 and Figure 6 To illustrate this embodiment: the difference between this embodiment and the full fiber optic current transformer sensing device with active temperature compensation described in the first embodiment is that the heating device 7-3-2 in the temperature self-balancing device 7-3 It is composed of two heating solenoids with opposite winding directions, which generate two magnetic fields with the same magnitude and opposite directions. The effects of these two magnetic fields on the transformer can cancel each other out, preventing the interference generated by the heating solenoid 7-3-2 The magnetic field affects the measurement results of the all-fiber-optic current transformer, and the heating solenoid 7-3-2 is equidistantly placed on both sides of the temperature sensor 7-3-1, so that the measurement point where the temperature sensor 7-3-1 is located The temperature rise of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com