Unequal interval symmetrical ventilating ducts for stators and rotors of air and water-cooled wind driven generator

A wind turbine, symmetrical ventilation technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of high temperature in the middle and uneven temperature distribution of the iron core axis, etc. Achieve the effect of improving heat transfer capacity and solving uneven temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

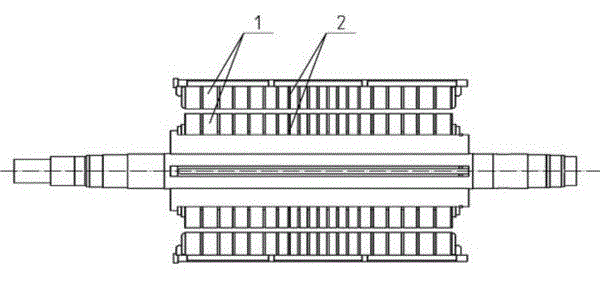

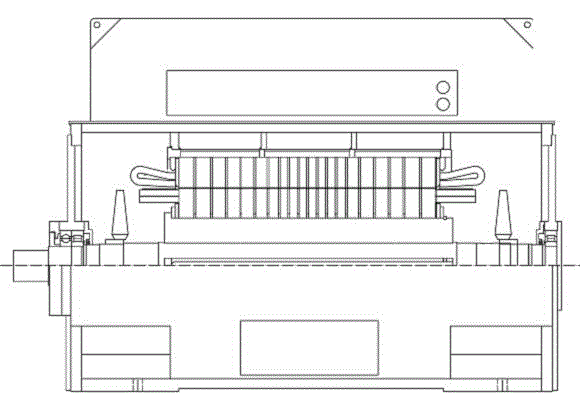

[0009] Such as figure 1 , 2 As shown, the present invention is an air-water-cooled wind power generator with unequal spacing and symmetrical air passages between the stator and rotor. The iron cores 1 of the stator and rotor all adopt a segmented press-fit structure, and the length of each segment of the iron core 1 gradually decreases from the end to the middle and is symmetrically distributed. , Ventilation slots 2 are arranged between adjacent iron cores 1 to form radial air passages, the air passages of the stator and rotor have the same width, and the iron cores 1 of the stator and rotor are press-fitted and the air passages are aligned, and then they are rolled off the assembly line and dipped in paint , assembly and other processes to complete the general assembly of the generator, a symmetrical radial air path is formed inside the generator when it is running, and when the cooling air enters the iron core 1 of the stator and rotor, the symmetrical ventilation structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com