Novel efficient low-pressure-drop plate-fin type heat exchanger fin

A plate-fin heat exchanger with low pressure drop technology, applied in the field of fin structure, can solve the problems of small heat transfer coefficient and large flow channel pressure drop, achieve strong turbulent flow, reduce flow resistance, and improve heat transfer capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

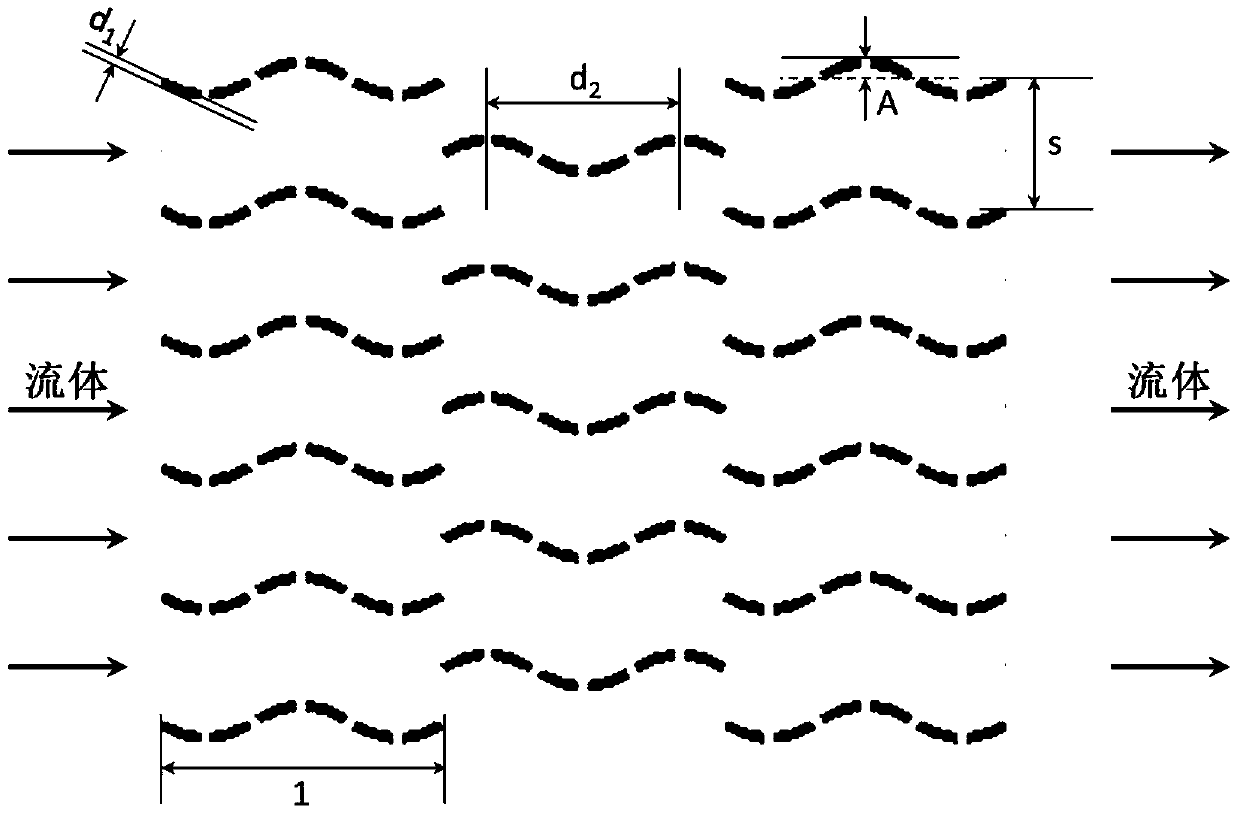

[0014] The fins are in the form of staggered corrugated fins, which are staggered in units of each unit wave, and each unit wave is divided into 6 segments by 5 cuts on average.

[0015] The wavelength of each unit wave is d 2 = 15 mm.

[0016] The amplitude of the unit wave is A=2.0mm.

[0017] The pitch of the fins is s=6mm.

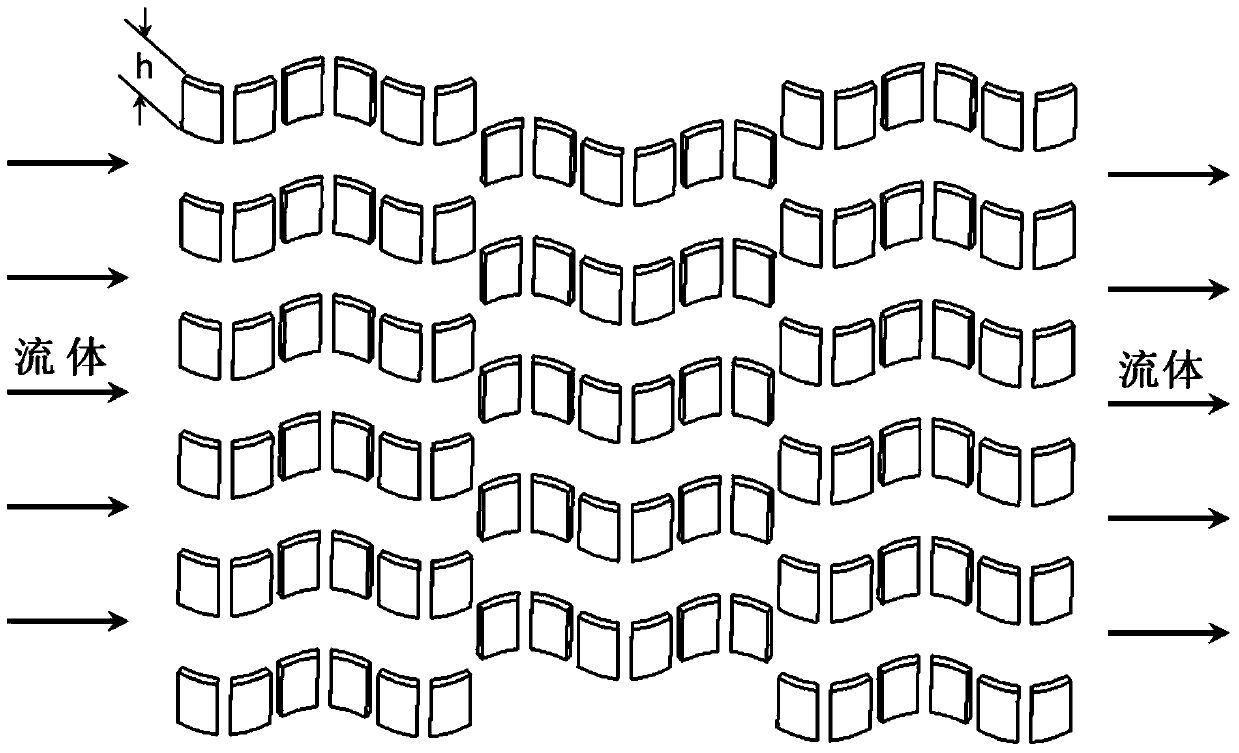

[0018] fin thickness d 1 is 0.5mm; the height h of the fins is 9.5mm.

[0019] Compared with conventional continuous corrugated fins with the same fin thickness, height, unit wavelength, wave amplitude and pitch, this embodiment can increase the heat transfer coefficient by 15-25% under the same pressure drop condition, and the fin weight Reduced by more than 15%. Compared with conventional sawtooth fins with the same fin thickness, height, unit wavelength, amplitude and pitch, this embodiment can reduce the pressure drop by 10-20% and reduce the weight of the fins under the same heat transfer coefficient. More than 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com