Double-layer hot air distribution pipe

A hot air distribution, double-layer technology, applied in the direction of pipes, branch pipelines, pipes/pipe joints/fittings, etc., can solve the problems of low temperature on both sides, uneven temperature distribution, high central temperature, and improve the difference in hot air quality , The effect of solving uneven temperature distribution and reducing the temperature difference of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

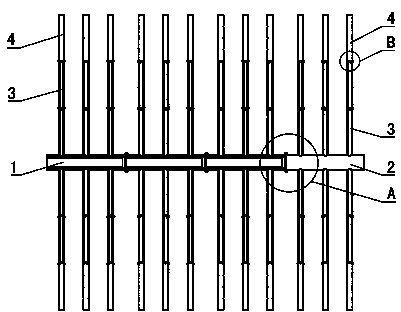

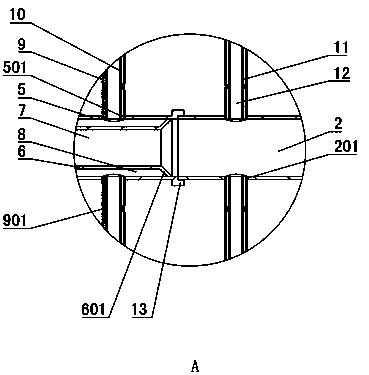

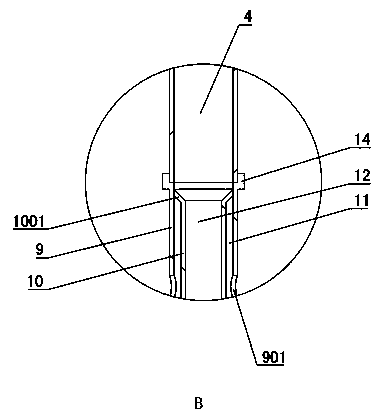

[0046] like Figure 1~5 As shown: in this embodiment, the main pipe 1 is provided with three sections connected head to tail along the axial direction, and the left end of each section of the main pipe 1 is the air inlet end, and the right end is the air outlet end. 2. Three branch pipes 3 are evenly distributed on the upper and lower sides of each section of the main pipe 1. The branch pipes 3 are arranged along the radial direction of the main pipe 1. The right end of the main pipe end pipe 2 is closed, and the upper and lower sides of the main pipe end pipe 2 are also symmetrically arranged. Three branch pipes 3. The end of each branch pipe 3 close to the main pipe 1 or the end pipe 2 of the main pipe is the air inlet end, and the end of each branch pipe 3 far away from the main pipe 1 or away from the main pipe end pipe 2 is the gas outlet end, and each branch pipe 3 is provided with a head-to-tail connection in the axial direction In the two sections, the gas outlet end ...

Embodiment 2

[0058] like Figure 6~7 As shown: the difference between embodiment 2 and embodiment 1 is that the delivery main pipe docking cover 601 of the main delivery main pipe 6 is spaced apart from the inner wall of the corresponding distribution main pipe 5 of this section, that is, both ends of the main pipe distribution chamber 8 are open. The delivery branch pipe docking cover 1001 of the delivery branch pipe 10 is spaced apart from the inner wall of the corresponding distribution branch pipe 9 , that is, both ends of the distribution chamber 11 of the branch pipe are open. Ensure that the hot air flow is more stable.

Embodiment 3

[0060] like Figure 8~12 As shown: the difference between embodiment 3 and embodiment 1 is that a pre-allocation main pipe 16 is arranged between the distribution main pipe 5 and the conveying main pipe 6 of each section of main pipe 1, and the pre-allocation main pipe 16 and the corresponding distribution main pipe 5 and the conveying main pipe 6 They are evenly spaced, so that a main pipe distribution cavity 8 is formed between the pre-distribution main pipe 16 and the distribution main pipe 5, and a main pipe pre-distribution chamber 18 is formed between the delivery main pipe 6 and the pre-distribution main pipe 16. The intake end of the conveying main pipe 6 is arranged within the intake end of the pre-distribution main pipe 16, thereby forming a gap for connecting the pre-distribution main pipe 16 intake end and the conveying main pipe 6 intake end at the pre-distribution main pipe 16 intake end. The main pipe communicates with the chamber 17.

[0061] The two sides bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com