Hydride gas phase extent device for manufacturing thick film nitride material

A technology of hydride gas phase and nitride, which is applied in the direction of final product manufacturing, metal material coating process, sustainable manufacturing/processing, etc., can solve the problems of low quality, uneven growth surface reaction, serious side reactions, etc., to achieve Improve temperature controllability and uniformity, solve uneven temperature distribution, and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

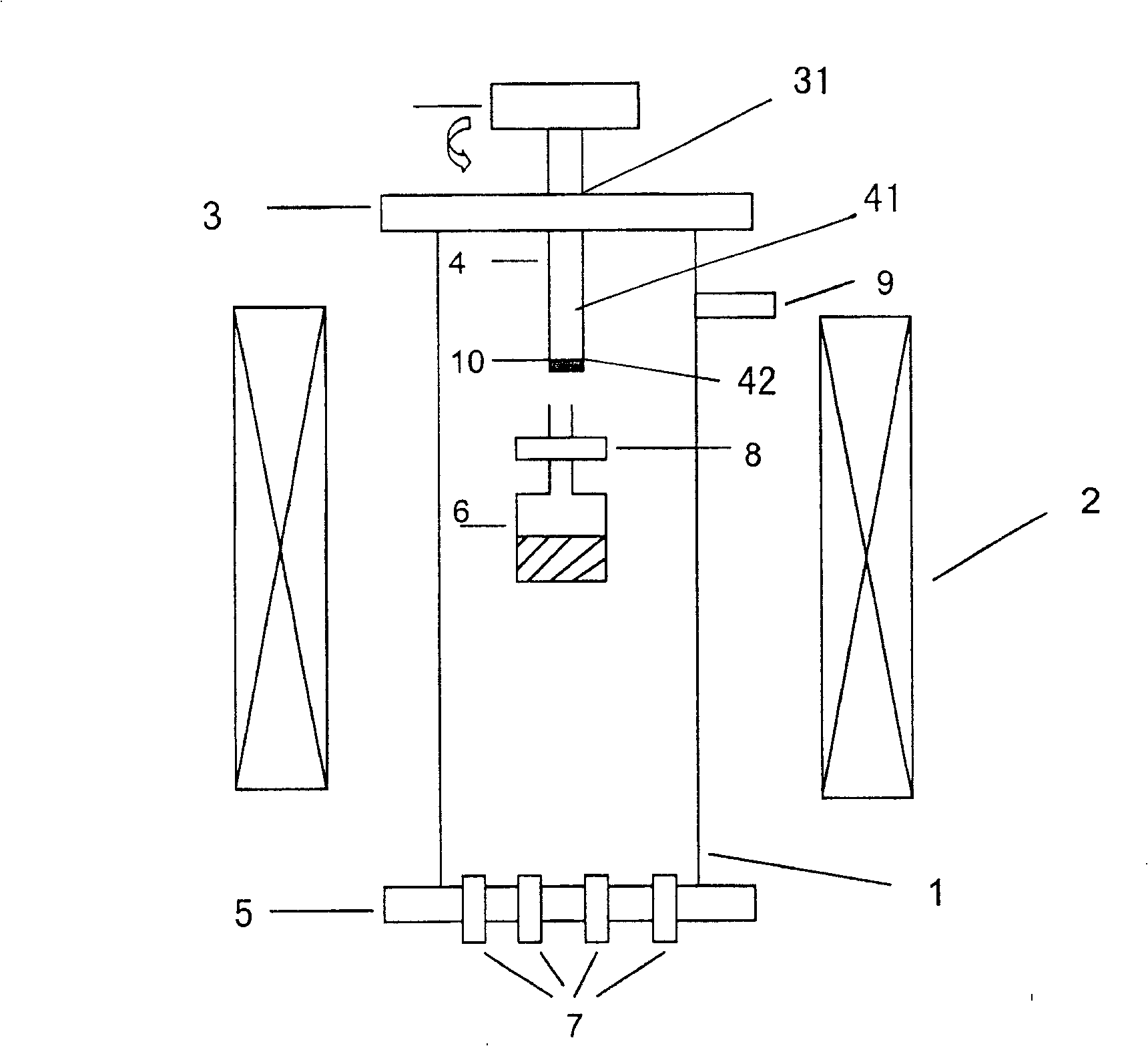

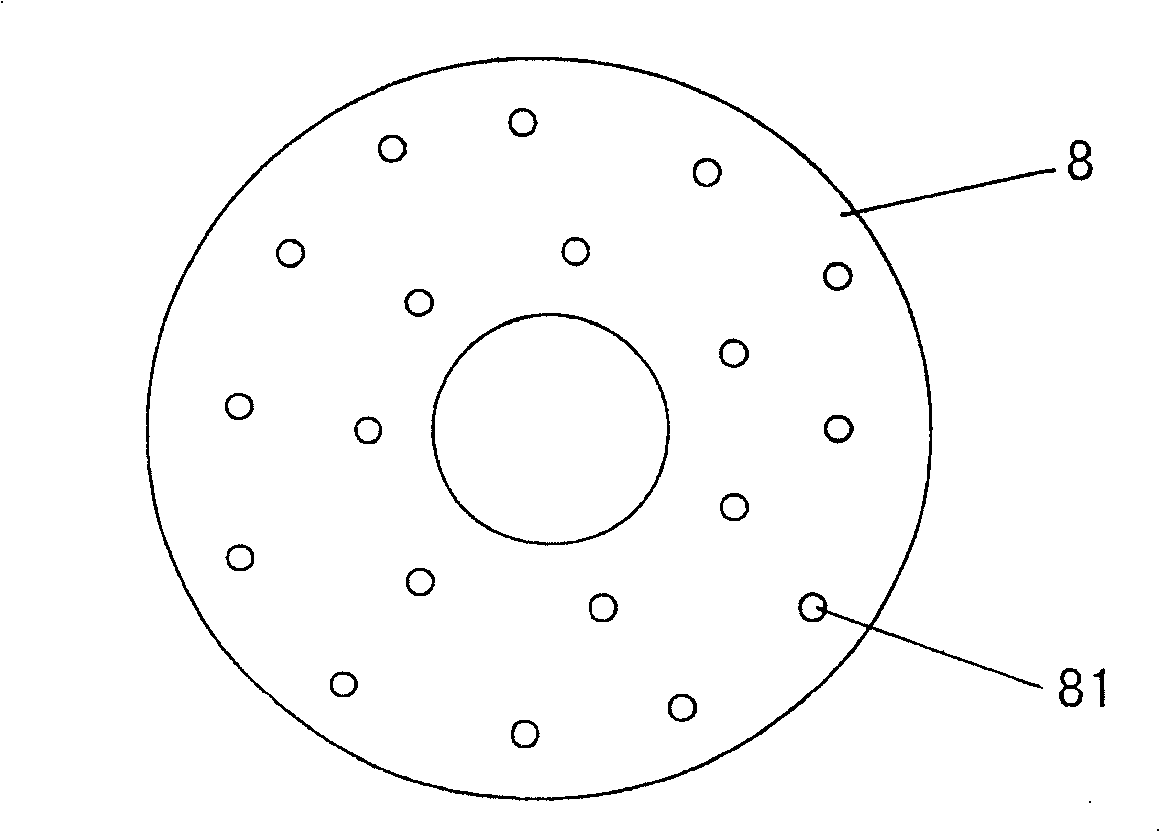

[0033] Taking the growth of GaN material as an example, the growth process flow of the present invention is: the quartz epitaxial growth chamber 1 is heated by the growth chamber heating device 2; the growth chamber heating device 2 is divided into multi-temperature zone heating; 850°C, substrate 10 temperature is 1050°C, carrier gas, reaction gas HCl and NH 3 Enter the quartz epitaxial growth chamber 1 from the air inlet 7 at the bottom of the quartz epitaxial growth chamber 1; the carrier gas transports the reaction gas HCl to the metal reaction source placer 6, and the HCl reacts with the metal source to generate GaCl gas; the carrier gas transports GaCl to the substrate Bottom 10; at the same time, the carrier gas transports the reaction gas NH 3 Spray to the substrate 10 through the ammonia shower 8; GaCl and NH 3 GaN is generated by reaction on the substrate 10; during growth, the speed-regulating motor controls the rotation of the substrate and the lifting device 4 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com