Manufacturing method for reinforcement type liquid crystal display module

A liquid crystal display module and heater technology, applied in the direction of ohmic resistance heating, instruments, electric heating devices, etc., can solve the problems of uneven temperature distribution of the liquid crystal screen, difficulty in graphic design and processing, etc., to solve the problem of uneven temperature distribution of the liquid crystal screen, easy Effects of processing and processing, easy diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of a reinforced liquid crystal display module heater, which comprises the following steps:

[0023] First, choose glass, plexiglass, PC, PMMA or polyimide film as the heater substrate. And it is cleaned to meet the subsequent preparation requirements;

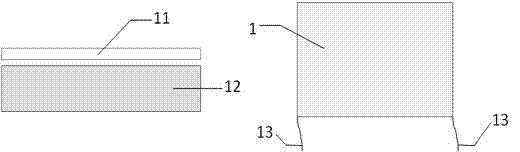

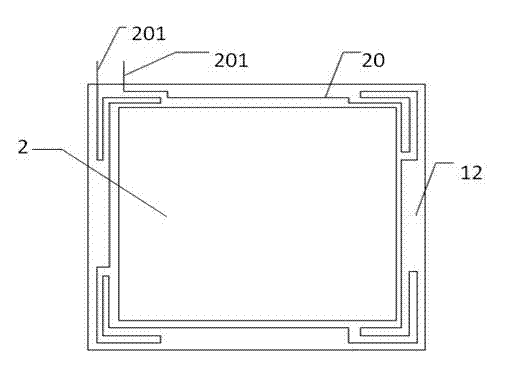

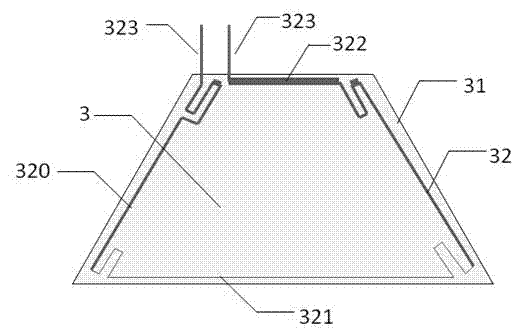

[0024] Secondly, design the heating pattern shape on the substrate to meet the heating requirements; the heating pattern shape can be the overall shape consistent with the heater shape (such as figure 1 ), can also be formed by connecting several strips or block alloy materials ( figure 2 ), can also be a combination of bar and block patterns (such as image 3 ). A protective layer is applied, wherein the protective layer has a lower gasification temperature, and the temperature control of the film-forming interface is realized through gasification.

[0025] Third, using alloy materials as heating materials, through one or more of chemical vapor deposition, physical vapor deposition, mechani...

example 1

[0032] Select the optical glass of Shenzhen CSG Company as the substrate for the preparation of the heater, and cut it into a size of 60mm×60mm×1mm. Optical glass substrates were ultrasonically cleaned with isopropanol and pure aqueous solution for 5 min, followed by UV and ozone for 30 min. After the cleaning process, the optical glass substrate was plasma treated for 10 minutes in a vacuum not greater than 0.1 mTorr.

[0033] Coat a layer of low-temperature protective layer on the surface of optical glass by spin-coating process. Conventional protective materials can be used for the low-temperature protective layer. The thickness of the protective layer should be controlled between 10-30 microns, preferably 20 microns, and the thickness uniformity is about 98%.

[0034] Copper-chromium alloy sputtering and optical glass are used to form a film by physical vapor deposition process, the distance between the alloy target and the optical glass is adjusted to about 30cm, and the ...

example 2

[0037] Cut the constantan alloy foil laminated with polyimide film on one side to a size of 50mm×50mm, pre-fix it on a glass substrate of the same size, clean it ultrasonically with isopropanol and pure aqueous solution for 5 minutes, and then use UV and ozone Wash for 30 minutes. After the cleaning process, it is plasma treated for 10 minutes in a vacuum not greater than 0.1 mTorr.

[0038] Design the heating layer pattern and process the mask plate according to the requirements of the uniformity of the low-temperature heating temperature distribution of the liquid crystal screen of this size.

[0039] Then prepare the designed heating layer pattern by spin coating, photolithography, etching and other processes, use metal wire welding to lead out the heating electrode, and remove the pre-fixed constantan foil from the glass substrate to complete the preparation of the heater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com