Lithium ion battery, positive paste, positive pole plate and preparation method of positive pole plate

A lithium-ion battery and positive electrode slurry technology, which is applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems that affect the specific capacity and cycle performance of the battery, and cannot improve the specific energy of the battery, so as to achieve the improvement of compaction density, The effect of increasing the specific energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

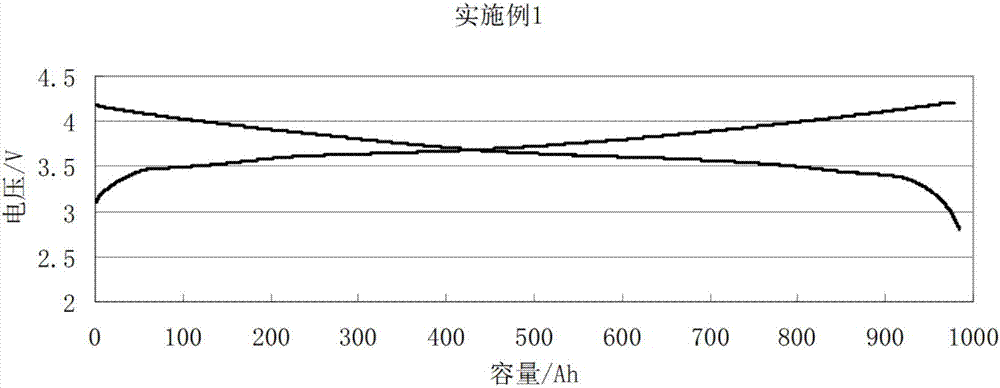

Embodiment 1

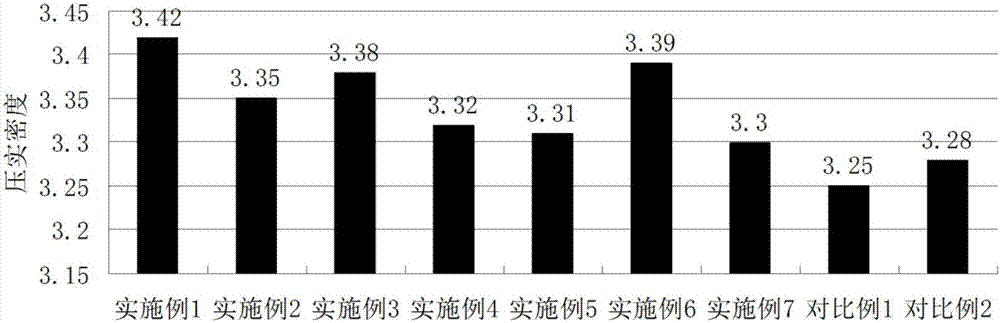

[0043] In this example, using D 50 8.0μm nickel cobalt lithium manganese oxide material A and D 50 The 10.5 μm nickel-cobalt lithium manganese oxide material B was prepared according to the ratio of 0.3:0.7 (A:B, w:w).

[0044] In this example, the solvent is NMP, the binder is PVDF, and the conductive agent is SP.

[0045] In the positive electrode slurry in this example, the weight ratio (w / w) of nickel cobalt lithium manganese oxide material (A and B): binder: conductive agent is 94:2:4.

[0046] In the positive electrode slurry in this example, the mass fraction of the solvent is: 35%.

[0047] The specific preparation process of positive electrode slurry in this example is as follows:

[0048] 1) Mix material A and material B, and stir at a mixing speed of 20r / min, so that the two materials are fully mixed to obtain mixed material C

[0049] 2) Mix 100% solvent and 50% binder, first stir at a slow speed of 20r / min, and then quickly stir at 1500r / min to obtain glue sol...

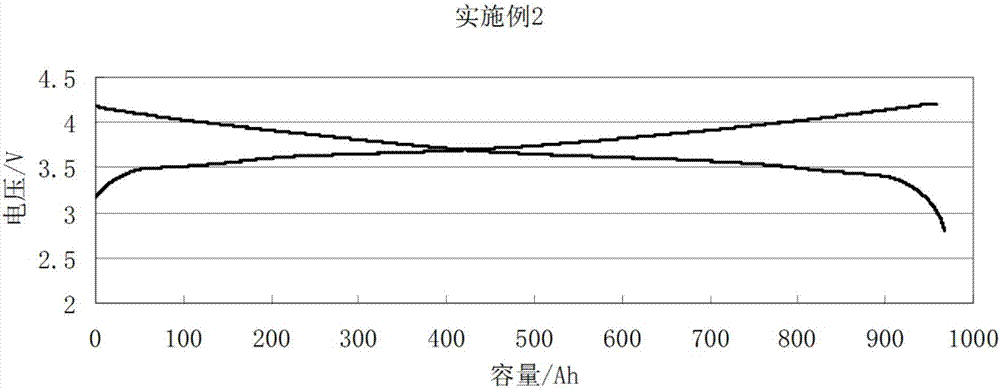

Embodiment 2

[0058] In this example, using D 50 8.5μm nickel cobalt lithium manganese oxide material A and D 50 The 11 μm nickel-cobalt lithium manganese oxide material B was prepared at the ratio of 0.5:0.5 (A:B, w:w) to prepare the positive electrode slurry.

[0059] The types of solvent, binder and conductive agent, and the mass fraction of solvent in the positive electrode slurry in this example are the same as those in Example 1.

[0060] In the positive electrode slurry in this example, the weight ratio (w / w) of nickel cobalt lithium manganese oxide material (A and B): binder: conductive agent is 95:2:3.

[0061] At the same time, the relevant preparation steps of the positive electrode slurry, positive electrode sheet, and battery in this example are also the same as in Example 1. For the charge and discharge curve of lithium ion battery 2 prepared in this example, please refer to image 3 , for the compacted density of the positive electrode sheet material in this example, see f...

Embodiment 3

[0063] In this example, using D 50 7.5μm nickel cobalt lithium manganese oxide material A and D 50 The 10.5 μm nickel-cobalt-lithium manganese oxide material B was prepared according to the ratio of 0.2:0.8 (A:B, w:w).

[0064] The types of solvent, binder and conductive agent, and the mass fraction of solvent in the positive electrode slurry in this example are the same as those in Example 1.

[0065] In the positive electrode slurry in this example, the weight ratio (w / w) of nickel cobalt lithium manganese oxide material (A and B): binder: conductive agent is 93:1:6.

[0066] Wherein, the specific preparation process of positive electrode slurry in this example is as follows:

[0067] 1) Mix material A and material B, and stir at a mixing speed of 40r / min, so that the two materials are fully mixed to obtain mixed material C

[0068] 2) Mix 100% solvent with 50% binder, first stir at a slow speed of 40r / min, and then stir at a fast speed of 3000r / min to obtain glue solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com