A silicon-carbon composite negative electrode material and a preparation method thereof

A negative electrode material and silicon-carbon composite technology, applied in nanotechnology for materials and surface science, battery electrodes, electrical components, etc., can solve problems such as the specific capacity limitation of silicon materials, achieve good conductivity and increase tap density , the effect of uniform doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

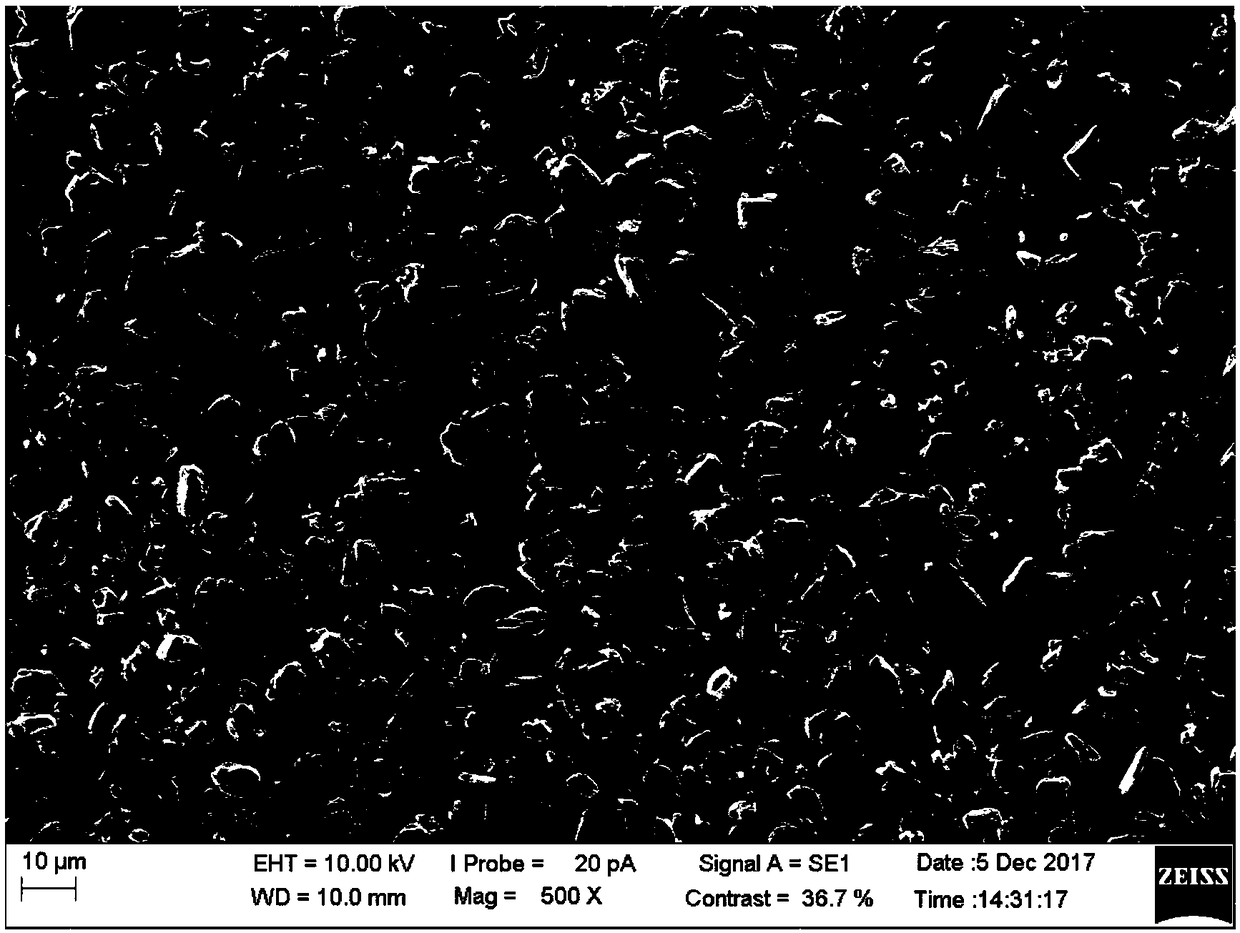

Image

Examples

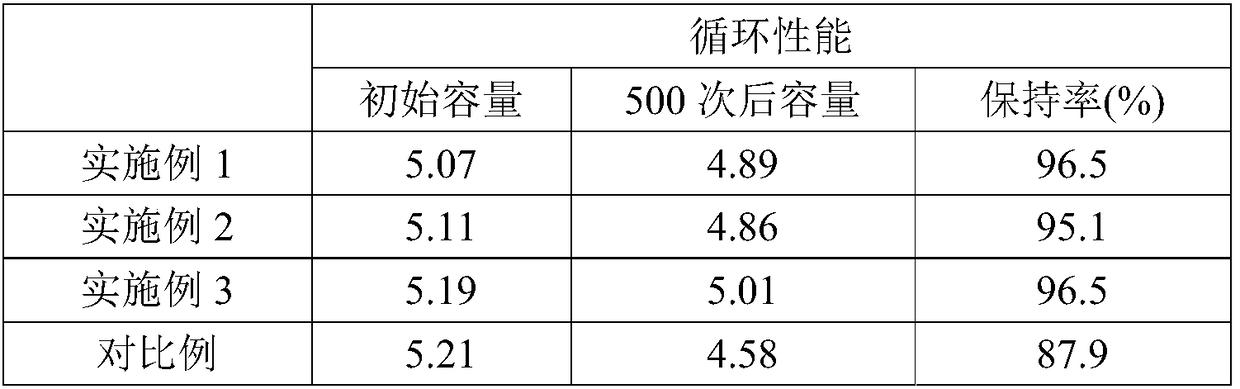

Embodiment 1

[0038] The preparation method of the silicon-carbon composite negative electrode material of this embodiment comprises the following steps:

[0039] 1) In the reaction kettle, add 100g of oxidized pitch and 1000mL of carbon disulfide, and stir rapidly at a speed of 100rpm for 30min, so that the oxidized pitch and carbon disulfide are evenly mixed. Then heat up to 90°C, add 3g of AlCl 3 and 12g of CCl 4 , carry out the cross-linking reaction for 1 hour, and then filter. The obtained solid composite material is heated to 1100° C. under an argon atmosphere, and kept for 2 hours; then cooled to room temperature, and the porous carbon material is obtained by pulverization and classification.

[0040] 2) Add 0.5g of γ-aminopropyltriethoxysilane to 100mL of N,N-dimethylformamide, disperse evenly, add 3g of the above-mentioned porous carbon material, mix evenly, and spray dry. The inlet temperature is 150° C., and a modified porous carbon material is obtained.

[0041] 3) Transfer ...

Embodiment 2

[0045] The preparation method of the silicon-carbon composite negative electrode material of this embodiment comprises the following steps:

[0046] 1) In the reaction kettle, add 50g of oxidized pitch and 1000mL of carbon disulfide, and stir rapidly at a speed of 50rpm for 30min, so that the oxidized pitch and carbon disulfide are evenly mixed. Then heat up to 80°C, add 5g of AlCl 3 and 15g of CCl 4 , carry out cross-linking reaction for 2 hours, and then filter. The obtained solid composite material is heated up to 1200° C. in an argon atmosphere, and kept for 1 hour; then cooled to room temperature, crushed and classified to obtain a porous carbon material.

[0047] 2) Add 0.1g of γ-(2,3-glycidoxy)propyltrimethoxysilane to 100mL of N-N-dimethylacetamide, disperse evenly, add 5g of the above porous carbon material, mix evenly and spray drying, the inlet temperature during spray drying is 100° C., and a modified porous carbon material is obtained.

[0048] 3) Transfer the ...

Embodiment 3

[0052] The preparation method of the silicon-carbon composite negative electrode material of this embodiment comprises the following steps:

[0053] 1) In the reaction kettle, add 150g of oxidized pitch and 1000mL of carbon disulfide, and stir rapidly at a speed of 200rpm for 30min, so that the oxidized pitch and carbon disulfide are evenly mixed. Then heat up to 100°C, add 1g of AlCl 3 and 10 g of CCl 4 , carry out the cross-linking reaction for 0.5h, and then filter, and raise the temperature of the obtained solid composite material to 1000° C. under an argon atmosphere, and keep it warm for 3 hours; then cool down to room temperature, pulverize and classify to obtain a porous carbon material.

[0054] 2) Add 1g of dimethyldimethoxysilane to 100mL of γ-butyrolactone, disperse evenly, add 1g of the above-mentioned porous carbon material, mix evenly, and spray dry. The inlet temperature during spray drying is 120°C. A modified porous carbon material is obtained.

[0055] 3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com