Method for synthesizing spheroidal lithium phosphate

A technology of metallic lithium and phosphoric acid, applied in non-metallic elements, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of single olivine phase, difficult to control conditions, difficult to obtain, etc., and achieve excellent cycle performance, low cost, energy The effect of less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Will Li 2 CO 3 , FeC 2 o 4 2H 2 O, NH 4 h 2 PO 4 Mix evenly at a molar ratio of 0.55:1:1, add sugar with a molar ratio of 5% to lithium ions during mixing, and pyrolyze at 400° C. for 5 hours in a sealed tube furnace protected by nitrogen. After cooling, mix the intermediate product with 2 times the molar ratio of KCl, then sinter at 760°C for 3 hours, cool naturally, wash the initial product with deionized water, then wash with ethanol, filter and dry under vacuum at 100°C to obtain lithium iron phosphate granular products.

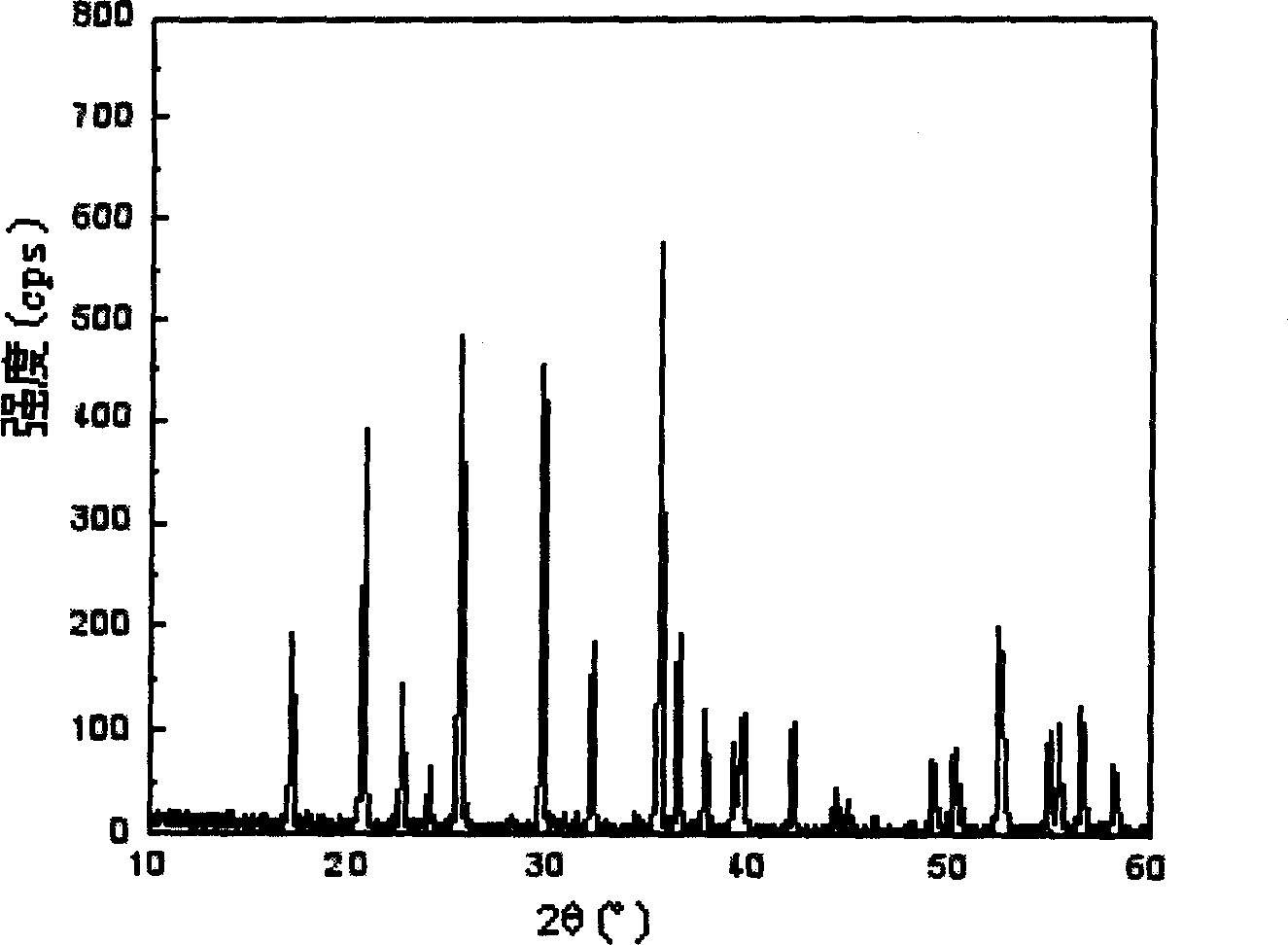

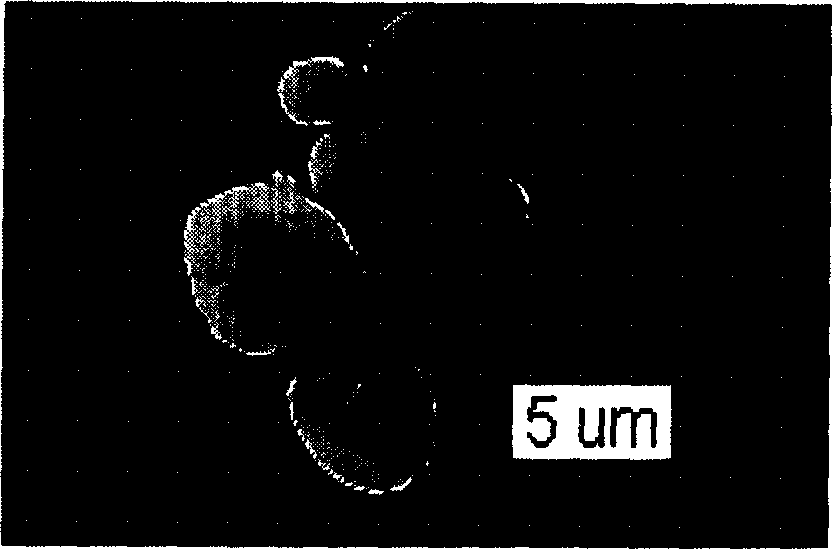

[0022] The obtained lithium iron phosphate product has an olivine structure with a tap density of 1.52g cm -3 . Adopt Cu target Kα radiation, λ=0.15406nm, obtain the X-ray diffraction pattern of this product, as figure 1 shown. Through field emission scanning electron microscopy, it can be seen that the lithium iron phosphate particles are spherical or spherical, with a diameter of 2-4 μm, such as figure 2 shown. The cyclic voltammet...

Embodiment 2

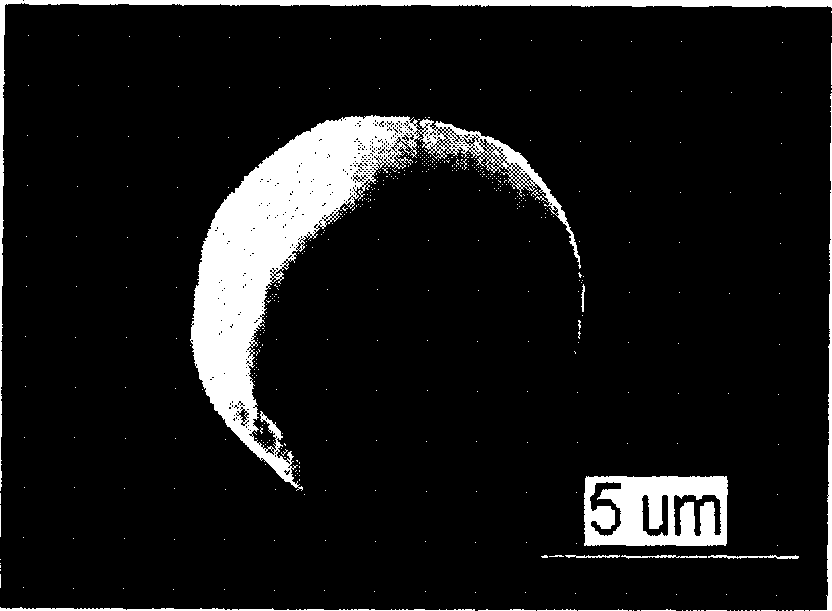

[0024] Will Li 2 CO 3 , FeC 2 o 4 2H 2 O, (NH 4 ) 2 HPO 4 Mix evenly at a molar ratio of 0.51:1:1, add citric acid with a molar ratio of 5% to lithium ions during mixing, and pyrolyze in a sealed tube furnace at 300°C for 12 hours, protected by nitrogen. After cooling, the intermediate product was mixed with 4 times the molar ratio of KCl, then sintered at 760°C for 10 hours, cooled naturally, the initial product was washed with deionized water, then with ethanol, filtered and dried under vacuum at 100°C. Such as image 3 As shown, the obtained product has an olivine structure, spherical particles, a diameter of 5-6 μm, and a tap density of 1.64 g cm -3 , the first discharge capacity is 121.3mAh·g -1 .

Embodiment 3

[0026] LiOH·H 2 O, NH 4 FePO 4 Mix evenly at a molar ratio of 1.2:1, and pyrolyze in a sealed tube furnace at 350°C for 24 hours, protected by nitrogen. After cooling, mix the intermediate product with 1 times the molar ratio of K 2 CO 3 Mix, then sinter at 900°C for 0.5 hour, cool naturally, wash the initial product with deionized water, then with ethanol, filter and dry under vacuum at 100°C. The obtained product has an olivine structure, the particles are spherical, the diameter is 5-7μm, and the tap density is 1.54g cm -3 , the first discharge capacity is 120.6mAh·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com