Preparation method of sulfur/graphene nano composite material, positive electrode of lithium ion battery and lithium ion battery

A nano-composite material, lithium-ion battery technology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve the problems of poor cycle stability and electrical conductivity, and achieve the effect of good cycle stability, easy storage, and not easy to be oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of graphite oxide: weigh 5.0g graphite and 3.75g NaNO respectively 3 Put it into a 1L beaker, stir vigorously, slowly add 150mL of concentrated sulfuric acid, stir for 0.5 hours, then slowly add 20g of KMnO 4 , Added in 0.5 hours, and continued to stir for 20 hours, the viscosity of the reactant increased, and the stirring was stopped to obtain a paste-like purple-red substance. After standing for 5 days, slowly add 500mL deionized water and 30mL H 2 o 2 At this time, the color of the solution becomes more obvious bright yellow. After the solution is fully reacted, it is centrifuged and washed to obtain graphite oxide.

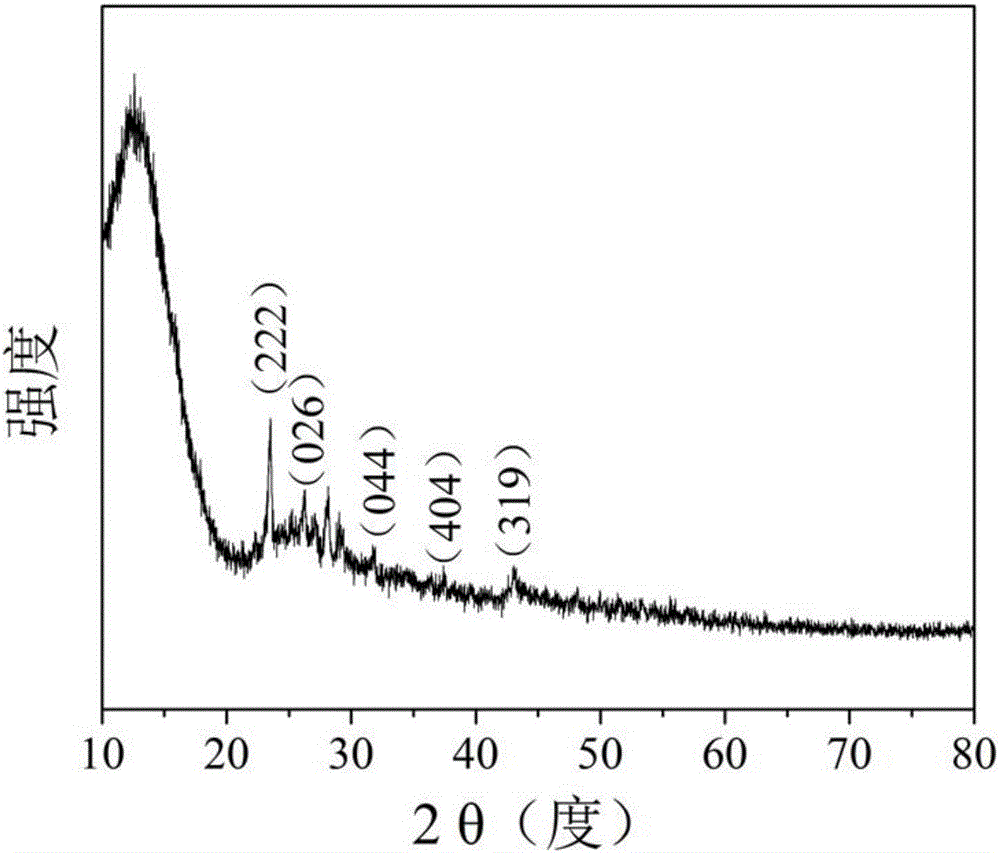

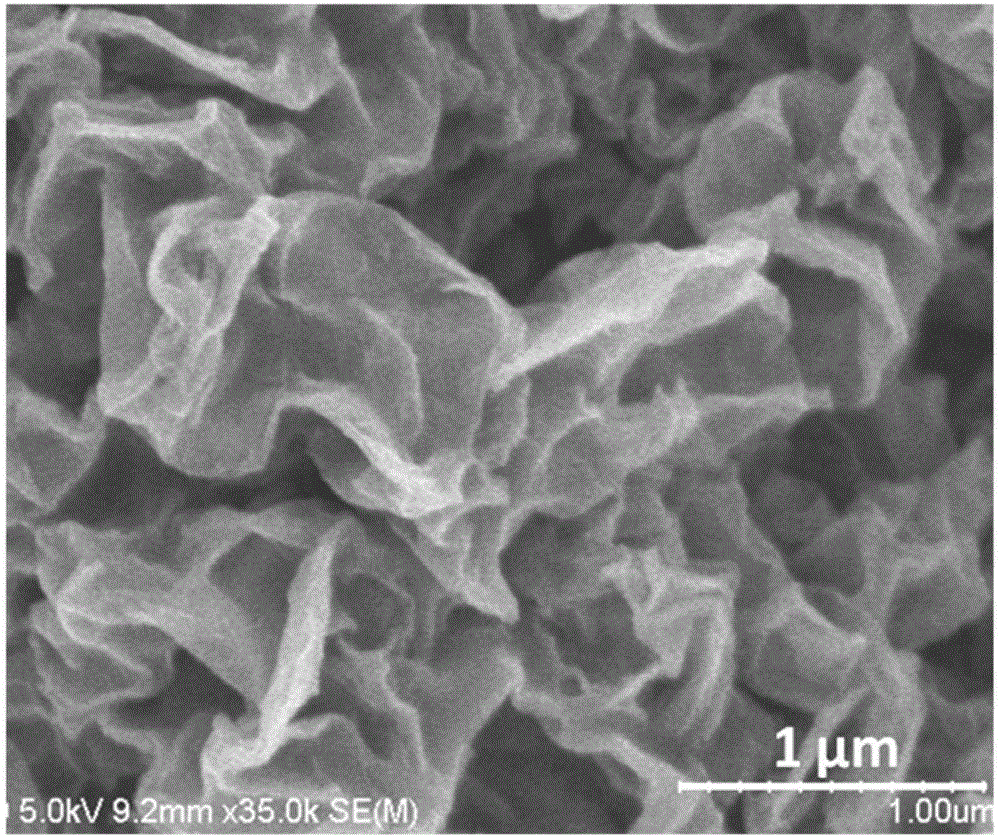

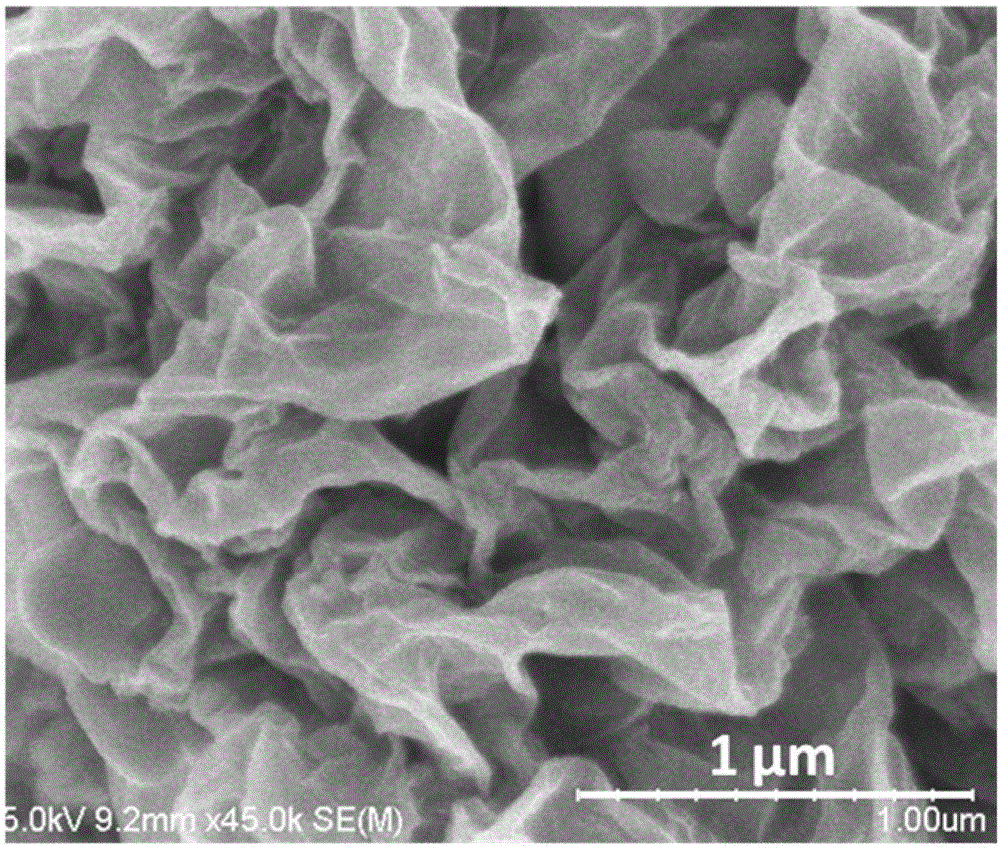

[0039] Hydrothermal process: Dissolve 70mg graphene oxide in 80mL deionized water, add 9mL concentrated sulfuric acid (ρ=1.84g / cm 3 ), ultrasonically dispersed for 3 hours, and then transferred to a reaction kettle, and reacted at a constant temperature of 220 ° C for 20 hours to obtain a three-dimensional columnar reduced graphene oxide,...

Embodiment 2

[0042] The preparation method of graphite oxide is with embodiment 1.

[0043] Hydrothermal process: Dissolve 70mg of graphene oxide in 80mL of deionized water, add 9mL of concentrated sulfuric acid, ultrasonically disperse for 3 hours, then transfer it to a reaction kettle, and react at a constant temperature of 160°C for 30 hours to obtain a three-dimensional columnar reduced graphene oxide. Wash collection.

[0044] Composite process: drop 0.02g of hydroxylamine hydrochloride into 40mL of water, add 2.8g of potassium thiosulfate, add 16mg of three-dimensional columnar reduced graphene oxide to the above mixed solution, soak at 15°C for 3 days, and then transfer it to the reaction kettle , react at a constant temperature of 90° C. for 24 hours, wash the product, dry it in vacuum at 60° C. for 4 hours, and collect the sulfur / graphene nanocomposite material.

Embodiment 3

[0046] The preparation method of graphite oxide is with embodiment 1.

[0047] Hydrothermal process: Dissolve 70mg of graphene oxide in 80mL of deionized water, add 9mL of concentrated sulfuric acid, ultrasonically disperse for 3 hours, then transfer it to a reaction kettle, and react at a constant temperature of 180°C for 20 hours to obtain a three-dimensional columnar reduced graphene oxide. Wash collection.

[0048] Composite process: drop 0.02g of hydroxylamine hydrochloride into 25mL of water, add 2.7g of potassium thiosulfate, add 19mg of three-dimensional columnar reduced graphene oxide to the above mixed solution, soak at 30°C for 2 days, and then transfer it to the reaction kettle , react at a constant temperature of 90° C. for 24 hours, wash the product, dry it in vacuum at 60° C. for 4 hours, and collect the sulfur / graphene nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com