Lithium ion battery and negative electrode composite electrode plate thereof

A lithium-ion battery and pole piece technology, which is applied to battery electrodes, secondary batteries, and secondary battery repair/maintenance, etc., can solve problems such as poor cycle performance and high expansion rate, and achieve improved conductivity, reduced expansion rate, and improved Effects of cycle performance and liquid absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

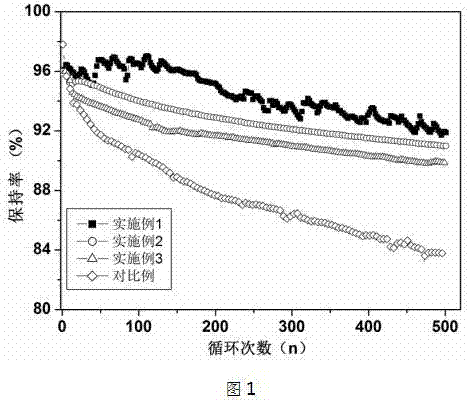

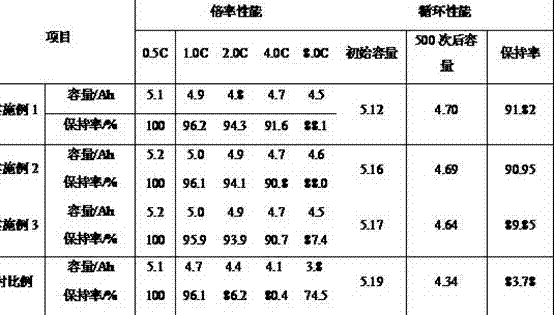

Examples

Embodiment 1

[0018] A kind of preparation method of lithium-ion battery negative pole composite electrode, has the following steps:

[0019] 1. Preparation of solution A: Add 0.3g of silicon powder with a particle size of 50nm to 5mL of dimethylformamide (DMF), and then add 0.3g of polyoxyethylene-polyoxypropylene-polyoxyethylene substance ( Abbreviated as P123) ultrasonic dispersion to form a uniform suspension, then add 0.8g of tetrabutyl titanate (C 16 h 36 0 4 Ti, TBOT), 0.3g of deionized water and 0.3g of triethanolamine (C 6 h 15 NO 3 ), magnetically stirred to form a homogeneous mixed solution, then slowly hydrolyzed at room temperature for 12h, and finally added 0.3g of polymethylmethacrylate (PMMA) and 0.1ml of hydrogen peroxide with a concentration of 10% and magnetically stirred for 1h A homogeneous viscous suspension A is obtained.

[0020] 2. Preparation of pole piece B: Coat the suspension on a 10-micron copper foil, and dry it at 60°C for 8 hours to obtain a Si / TBOT / PM...

Embodiment 2

[0023] 1. Preparation of solution A: Evenly disperse 0.1g of silicon powder with a particle size of 30nm in 5mL of dimethylformamide (DMF), and then add 0.1g of polyoxyethylene-polyoxypropylene-polyoxyethylene substance (referred to as P123) ultrasonic dispersion to form a uniform suspension, then add 0.7g of tetrabutyl titanate (C 16 h 36 0 4 Ti, TBOT), 0.2g of deionized water and 0.25g of triethanolamine (C 6 h 15 NO 3 ), magnetically stirred to form a uniform mixed solution, then slowly hydrolyzed at room temperature for 12h, and finally added 0.2g of polymethylmethacrylate (PMMA) and 0.1ml of hydrogen peroxide with a concentration of 30% and magnetically stirred for 1h A homogeneous viscous suspension A is obtained.

[0024] 2. Preparation of pole piece B: Coat the suspension on the copper foil and dry it at 60°C for 8 hours to obtain the Si / TBOT / PMMA pole piece. Soak in lithium carbonate solution for 1 hour and dry to obtain pole piece B.

[0025] 3. Preparation of...

Embodiment 3

[0027] 1. Preparation of solution A: Evenly disperse 0.5g of silicon powder with a particle size of 100nm in 5mL of dimethylformamide (DMF), and then add 0.5g of polyoxyethylene-polyoxypropylene-polyoxyethylene substance (referred to as P123) ultrasonic dispersion to form a uniform suspension, then add 0.9g of tetrabutyl titanate (C 16 h 36 0 4 Ti, TBOT), 0.3g of deionized water and 0.35g of triethanolamine (C 6 h 15 NO 3 ), magnetically stirred to form a homogeneous mixed solution, then slowly hydrolyzed at room temperature for 12h, and finally added 0.4g of polymethylmethacrylate (PMMA) and 0.1ml of hydrogen peroxide with a concentration of 0.5% and magnetically stirred for 1h A homogeneous viscous suspension A is obtained.

[0028] 2. Preparation of pole piece B: Coat the suspension on the copper foil and dry it at 60°C for 8 hours to obtain the Si / TBOT / PMMA pole piece. Lithium carbonate solution was soaked for 5 hours, and pole piece B was obtained after drying.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com