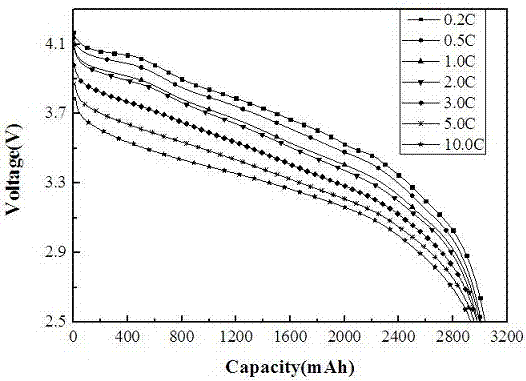

Novel lithium ion battery with high power and high energy density

A high-energy density, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large sacrifice of energy density and insufficient high-power output capacity of batteries, and achieve excellent rate discharge capacity, high Energy density, the effect of increasing gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

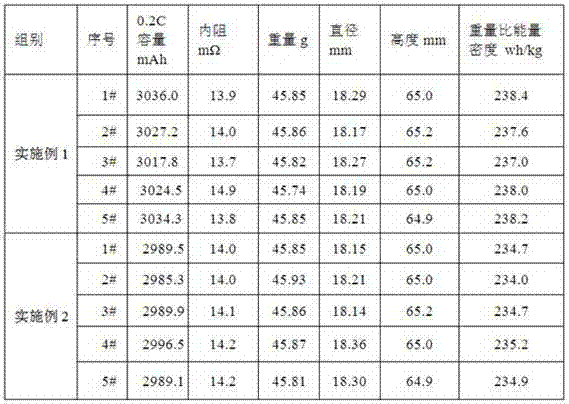

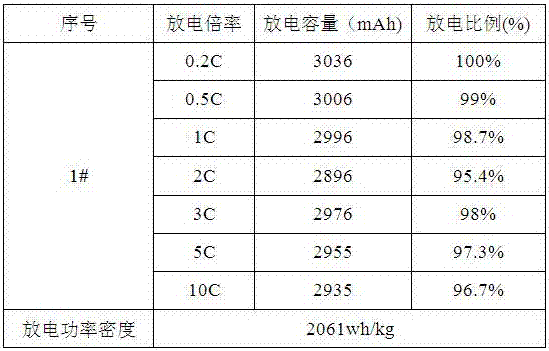

Embodiment 1

[0025] Taking the manufacturing process of a new type of high-power and high-energy-density lithium-ion battery with a capacity of 3000mAh as an example, the specific implementation process is as follows:

[0026] Preparation of positive electrode slurry:

[0027] Using N-dimethylpyrrolidone (NMP) as the solvent, the positive active material is high-nickel modified ternary material (NCA) (Tianjin Bamo Technology Co., Ltd. BMT920), and the conductive agent is superconducting carbon black (Super-P) and graphene, the binder is polyvinylidene fluoride (PVDF), and the weight ratio of NMP added is between 40% and 70% of solid matter. The weight percent of each substance in this embodiment is: NCA 95.5%, Super-P 1%, graphene 1%, PVDF 2.5%, NMP 65%.

[0028] (1) First prepare the positive electrode mixture: pre-disperse NCA and Super-P in the mixer for 1~2 hours, so that the conductive agent is evenly dispersed on the surface of NCA to obtain the positive electrode mixture.

[0029]...

Embodiment 2

[0040] The preparation of the positive electrode slurry and the electrolyte in this example are different from those in Example 1, and the rest of the production methods are the same as in Example 1. The preparation of the positive electrode slurry of the present embodiment: with NMP as solvent, active material is high-nickel ternary material (NMC811), conductive agent is Super-P and carbon nanotube (CNTs), binding agent is PVDF, NMP adds weight The ratio is between 50 and 72%. The weight percent of each substance in this example is: NMC 95.5%, Super-P 1%, CNTs 1%, PVDF 2.5%, NMP 65%. Add PVDF to NMP first, stir for 2~4h to prepare PVDF glue. Then add CNTs to the above PVDF glue and stir for 2~4 hours; then add Super-P to the above mixture and stir for 2~4 hours; finally add NMC to the above mixture, stir for 4~6 hours, then vacuumize and degas coating.

[0041] Electrolyte preparation: Lithium salt is lithium hexafluorophosphate (LiPF 6 ), the organic solvent is a ternary...

Embodiment 3

[0043] The preparation of the negative electrode slurry and the electrolyte in this example are different from those in Example 1, and the rest of the production methods are the same as in Example 1. The preparation of the negative electrode slurry of the present embodiment: with deionized water (H 2 O) is the solvent, the active material is SiO, soft carbon and artificial graphite, the conductive agent is superconducting carbon black (Super-P) and single-walled carbon nanotubes, and the binder is acrylate and sodium carboxymethyl cellulose (CMC ) composition, the addition ratio of deionized water is between 100% and 200%. The weight percent of each substance in this example is: SiO5.7%, soft carbon 19.25%, artificial graphite 68.7%, Super-P 2.30%, single-walled carbon nanotubes 0.05%, acrylate 2.5%, CMC 1.5%, H 2 O is 150% of solid matter. First prepare the negative electrode mixture, pre-disperse SiO soft carbon, artificial graphite, and Super-P in a mixer for 1~2 hours, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com