Preparation method and application of sulfur-nitrogen co-doped three-dimensional porous carbon nanosheet

A technology of three-dimensional porous and carbon nanosheets, applied in nanocarbon, nanotechnology, nanotechnology, etc., can solve problems such as low energy density and limited power density, achieve high specific capacity, high product yield, and improve cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Preparation of 1# sample;

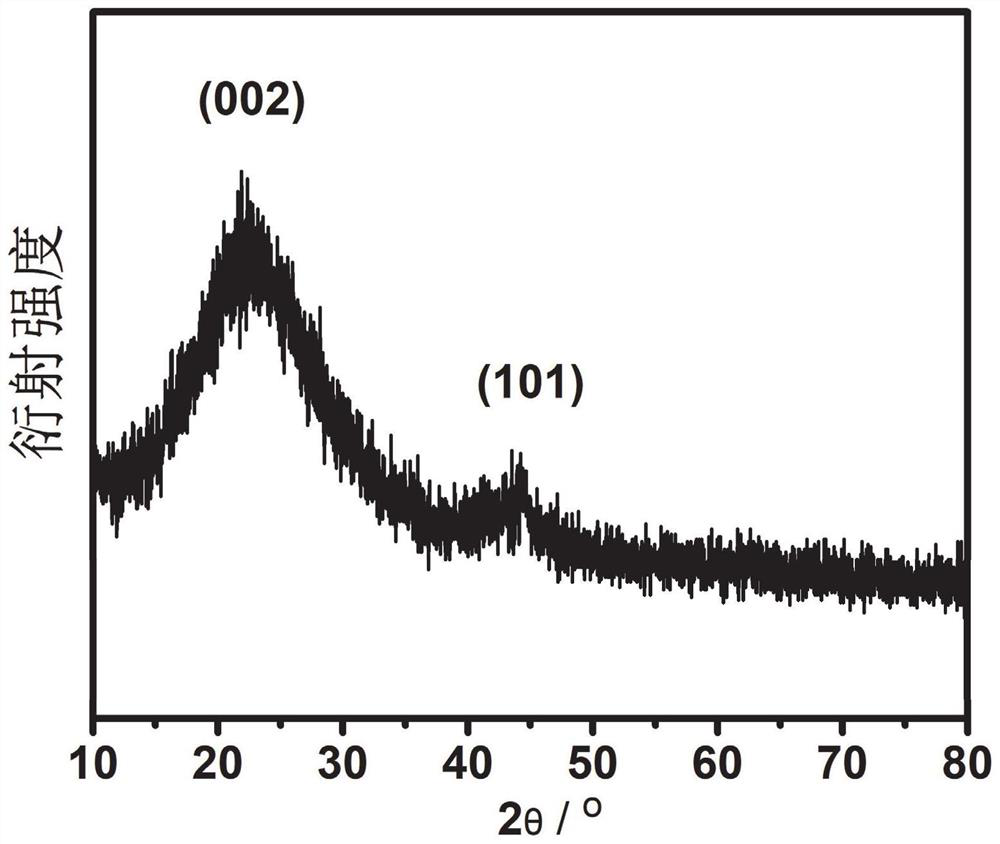

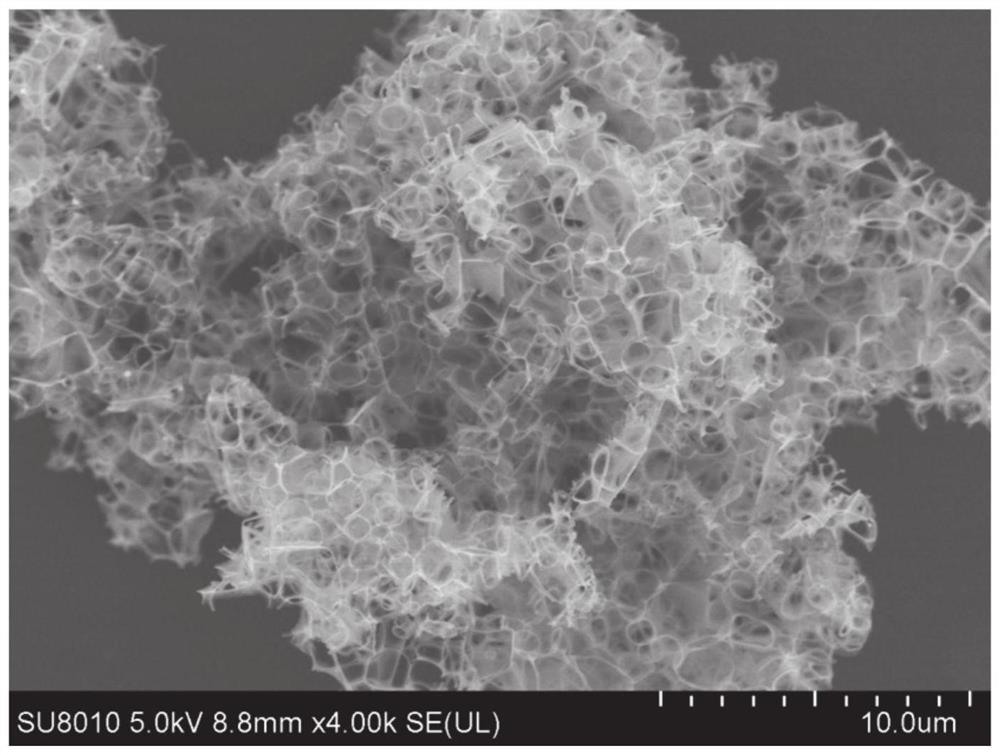

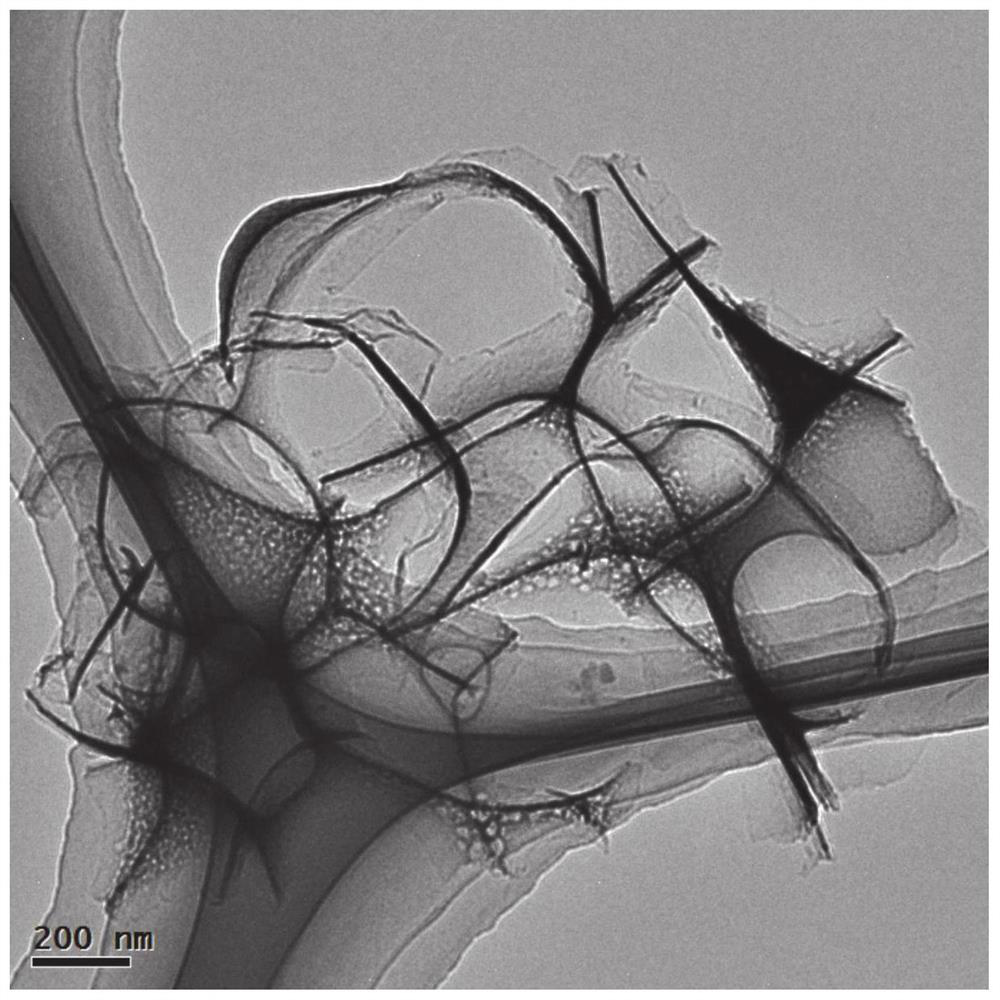

[0068] Dissolve 1g of citric acid, 0.5g of thiocyanuric acid and 5g of sodium chloride template successively in 50ml of water, stir in a water bath at 60°C for 1h, and then evaporate to dryness in an oven at 100°C for 24h to obtain carbon source, sulfur source, A mixture of nitrogen source and inorganic salt template (precursor powder); then the obtained mixture is heated to 750°C at a rate of 2°C / min in argon, and calcined for 2h to obtain the S-N-C / NaCl intermediate product; finally, S-N-C / NaCl intermediate product was dissolved in deionized water as NaCl template agent, stirred and then centrifuged and dried to obtain sulfur and nitrogen co-doped three-dimensional porous carbon nanosheets, which were recorded as 1# sample.

Embodiment 2

[0070] Preparation of 2# sample: The difference from the 1# sample in Example 1 is that the obtained precursor powder is heated up to 800°C at a rate of 3°C / min in argon, and calcined for 1 hour to obtain S-N-C / NaCl The intermediate product is recorded as 2# sample.

Embodiment 3

[0072] Preparation of 3# sample: The difference from 1# sample in Example 1 is that the obtained precursor powder is heated up to 700°C at a heating rate of 1°C / min in argon, and calcined for 2.5h to obtain S-N-C / The NaCl intermediate product is recorded as 3# sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com