Mesoporous carbon loaded sulfur/selenium flexible electrode based on three-dimensional graphite alkene self-supporting structure as well as preparation method and application thereof

A self-supporting structure, flexible electrode technology, applied in battery electrodes, structural parts, non-aqueous electrolyte battery electrodes, etc., can solve problems such as electrode energy density reduction, and achieve the effect of shortening the diffusion distance, improving transportation, and high capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

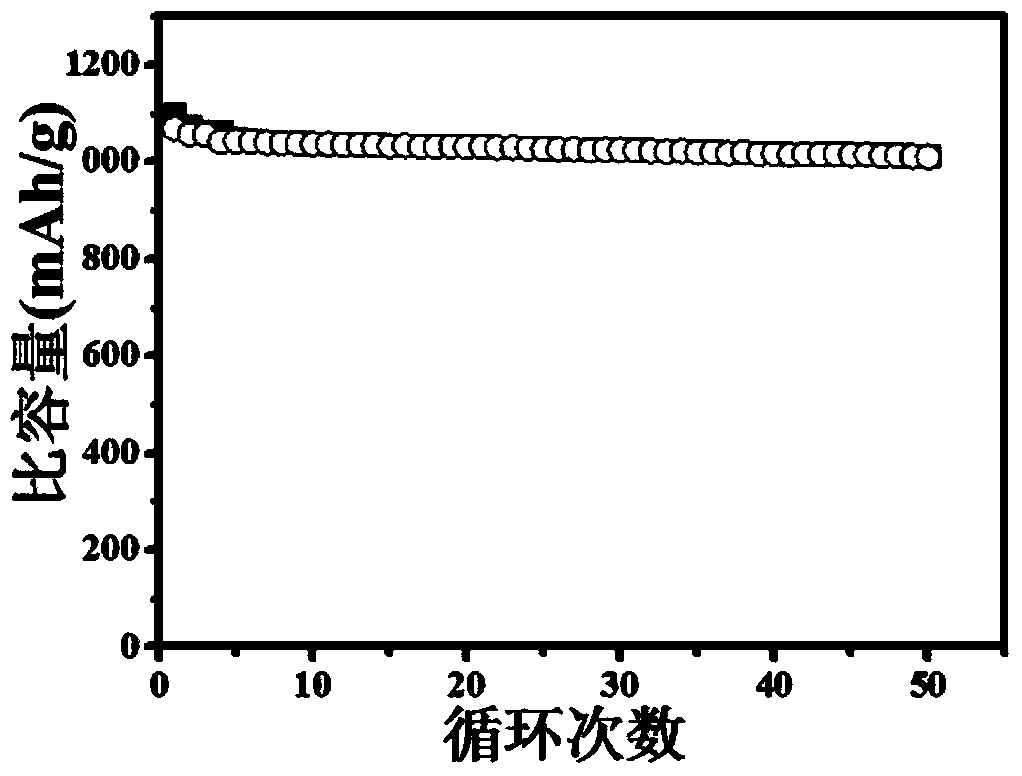

Embodiment 1

[0035] 1. The nickel foam cleaned by ethanol ultrasonic cleaning is heated to 900°C in a nitrogen atmosphere, and hydrogen and ethanol gas are introduced. Under the self-catalysis of the foam nickel, the graphene layered structure grows on the surface of the foam metal to obtain a three-dimensional foam Nickel-graphene is soaked in 100ml concentrated nitric acid with a mass fraction of 65% for 24 hours; it is washed with deionization until the solution is neutral, then soaked with ethanol and ether in turn, and vacuum-dried at 50°C for 8 hours after taking it out; Three-dimensional graphene self-supporting materials;

[0036] 2. Mix triblock copolymer F127, phenolic resin and absolute ethanol in a mass ratio of 1:1:1, stirring temperature is 50°C, stirring time is 8 hours, after stirring evenly, a yellow solution is obtained;

[0037] 3. Immerse the mesoporous carbon precursor solution into the three-dimensional graphene self-supporting material. After standing at room tempera...

Embodiment 2

[0043] 1. Heat up the nickel foam that has been ultrasonically cleaned with ethanol to 900°C in a nitrogen atmosphere, and feed hydrogen and ethanol gas. Under the self-catalysis of foamed nickel, the graphene layered structure grows on the surface of foamed nickel, and the obtained three-dimensional foamed nickel-graphene is soaked in 10ml68% concentrated nitric acid for 5 hours; wash with deionization until the solution is neutral , after soaking with ethanol and ether in turn, and vacuum drying at 20°C for 10 hours after taking it out, the three-dimensional graphene self-supporting material is obtained;

[0044] 2. Mix the triblock copolymer F127, phenolic resin and absolute ethanol in a mass ratio of 1:1:1, the stirring temperature is 20°C, and the stirring time is 15 hours. After stirring evenly, a yellow solution is obtained;

[0045] 3. Immerse the mesoporous carbon precursor solution into the three-dimensional graphene self-supporting material, and after standing at ro...

Embodiment 3

[0049] 1. Heat up the foam iron cleaned by ethanol ultrasonically to 700°C in an argon atmosphere, and then pass in hydrogen and ethanol gas. Under the self-catalysis of foam iron, the graphene lamellar structure grows on the surface of foam iron, and the three-dimensional foam iron-graphene that obtains is put into mass fraction and is soaked in 55ml concentrated nitric acid of 66% for 15 hours; Wash with deionization until the solution is Neutral, after soaking with ethanol and ether in turn, take it out and dry it in vacuum at 80°C for 6 hours to obtain a three-dimensional graphene self-supporting material;

[0050] 2. Mix triblock copolymer P123, phenolic resin and absolute ethanol at a mass ratio of 15:5:3, stirring temperature is 80°C, stirring time is 1h, after stirring evenly, a yellow solution is obtained;

[0051] 3. Immerse the mesoporous carbon precursor solution into the three-dimensional graphene self-supporting material, and after standing at room temperature fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com