Temperature-sensitive polymer electrolyte as well as preparation method and application thereof

A temperature-sensitive, electrolyte technology, used in hybrid capacitor electrolytes and other directions, can solve the problems that hinder the commercialization of high specific energy density and high power energy storage devices and other problems, and achieve easy promotion, easy diffusion of reaction heat, and low system viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 The preparation of thermosensitive type PAH-g-PNIPAAm copolymer

[0048] In 50mL methanol solution, add monomer 10g N-isopropylacrylamide and 150mg 4,4 , -Azobis(4-cyanovaleric acid), reacted at 66°C for 3h under nitrogen protection, then poured into hot water for precipitation, filtered, washed and dried to obtain PNIPAAm-COOH product. Take an appropriate amount of dry-treated PNIPAAm-COOH to prepare a 5% aqueous solution, react with 1-ethyl-3-(dimethylaminopropyl) carbodiimide at a low temperature for 2 days, and then add 1.0g of polyallylamine (PAH) continued to react for 2 days, and finally prepared PAH-g-PNIPAAm copolymer.

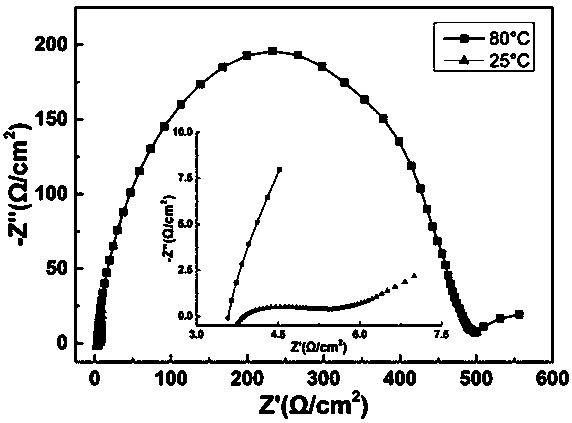

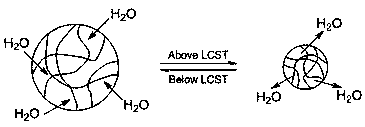

[0049] In order to study the temperature-sensitive phase transition behavior of PAH-g-PNIPAAm copolymer in aqueous solution, dynamic light scattering was used to test the change of its hydration radius (Rh) with temperature (concentration was 0.1 mg / mL). Below the LCST such as 30°C, the hydration radius of the polymer is 7.2nm, w...

Embodiment 2

[0050] Example 2 Preparation of thermosensitive P (NIPAM-co-NVP) hydrogel

[0051] Accurately weigh 0.9g N-isopropylacrylamide, 0.1g vinylpyrrolidone, 0.02g ammonium persulfate, 0.05g N,N-methylene bisacrylamide, dissolve in 10mL DMSO solvent, pour into tube In the reactor, the polymerization reaction is carried out by free radical thermal polymerization. The initial product was soaked in distilled water for 3 days to remove unreacted products and linear oligomers, then cut into pieces, and dried in vacuum for 30 hours at a temperature of 60°C.

[0052] In order to study the temperature-sensitive properties of the copolymer, the saturated swelling ratio in distilled water at different temperatures was tested on the dry rubber obtained in the experiment. At 10°C, the swelling ratio of the copolymer hydrogel reaches 31.1 g / g, and as the temperature increases, the swelling ratio of the hydrogel shrinks to 5 g / g at 50°C, and has reversible shrinkage swelling features. It can be...

Embodiment 3

[0053] Example 3 Preparation of thermosensitive poly N-vinyl caprolactam

[0054] Weigh 10.0 g of N-vinylcaprolactam and 0.157 g of azobisisobutyronitrile, dissolve it in 70 mL of dioxane, and stir for 30 min at room temperature under nitrogen gas. The reaction was transferred to an oil bath, and the temperature was raised to 68° C., and the nitrogen reaction was continued for 8 h. Dioxane was removed by suspension evaporation, and n-hexane was added for precipitation treatment, suction filtered, and vacuum-dried to obtain poly-N-vinyl caprolactam.

[0055] In order to observe the temperature-sensitive characteristics of the polymer, poly-N-vinylcaprolactam was prepared into a 1.0 mg / mL aqueous solution, and placed in an oven, and the temperature in the cavity was gradually increased. It can be clearly observed that the polymer solution gradually changes from an initial transparent state to a cloudy emulsion, and the phase transition temperature is about 58°C. As the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com