A kind of preparation method of doped modified lithium iron phosphate cathode material

A lithium iron phosphate and cathode material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of difficult quantitative control, high requirements for batching, mixing, grinding, and difficulty in mixing evenly, reaching high for the first time. The effect of discharge capacity, good application requirements, good cycle performance and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

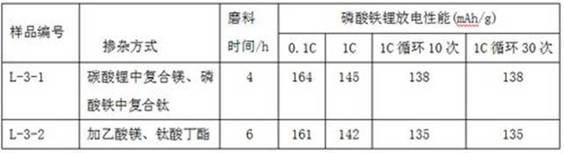

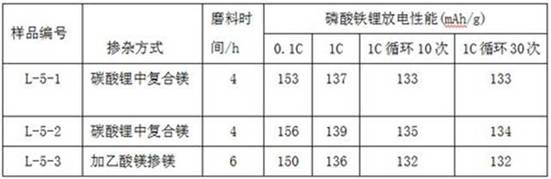

[0046] Using magnesium-containing lithium carbonate as a lithium source and iron phosphate as an iron source, lithium iron phosphate uniformly doped with magnesium is prepared.

Embodiment 1-1

[0048] Lithium iron phosphate (LiMg 0.001 Fe 0.999 PO 4 / C).

[0049] Take 48.00g of iron phosphate, 11.85g of lithium carbonate with a magnesium content of 0.06%, 8.00g of glucose and 72mL of absolute ethanol, put the above materials into a high-energy ball mill and grind for 3 hours, dry at 70°C, and then raise the temperature to 670°C under nitrogen protection. ℃ sintering for 13 hours, cooled to 25 ℃ with the furnace, out of the furnace, ground, sieved, and packaged to obtain magnesium-doped lithium iron phosphate product, the product number is L-1-1a.

Embodiment 1-2

[0051] Lithium iron phosphate (LiMg 0.01 Fe 0.99 PO 4 / C).

[0052] Take 48.00g of iron phosphate, 12.27g of lithium carbonate with a magnesium content of 0.65%, 8.00g of glucose and 80mL of absolute ethanol, put the above materials into a high-energy ball mill and grind for 3 hours, dry at 80°C, and then raise the temperature to 700°C under nitrogen protection. ℃ sintering for 10 hours, cooled to 40 ℃ with the furnace, taken out of the furnace, ground, sieved, and packaged to obtain magnesium-doped lithium iron phosphate product, the product number is L-1-1b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com