High-performance honeycomb-shaped lithium ion button battery

A button battery, honeycomb technology, applied in the field of high-performance honeycomb lithium-ion button battery, can solve the problems of volume change and rapid capacity fading, and achieve the effect of avoiding alignment difficulty and unevenness, improving cycle performance and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

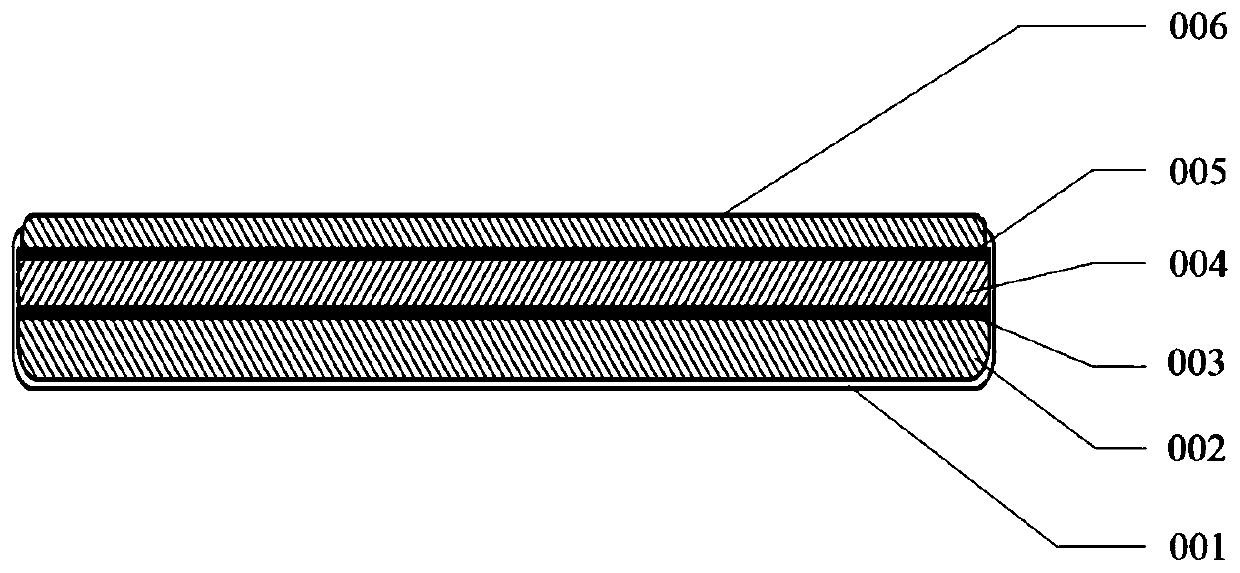

[0047] A honeycomb lithium-ion button battery arranged in a CR1220 rectangular array and its assembly:

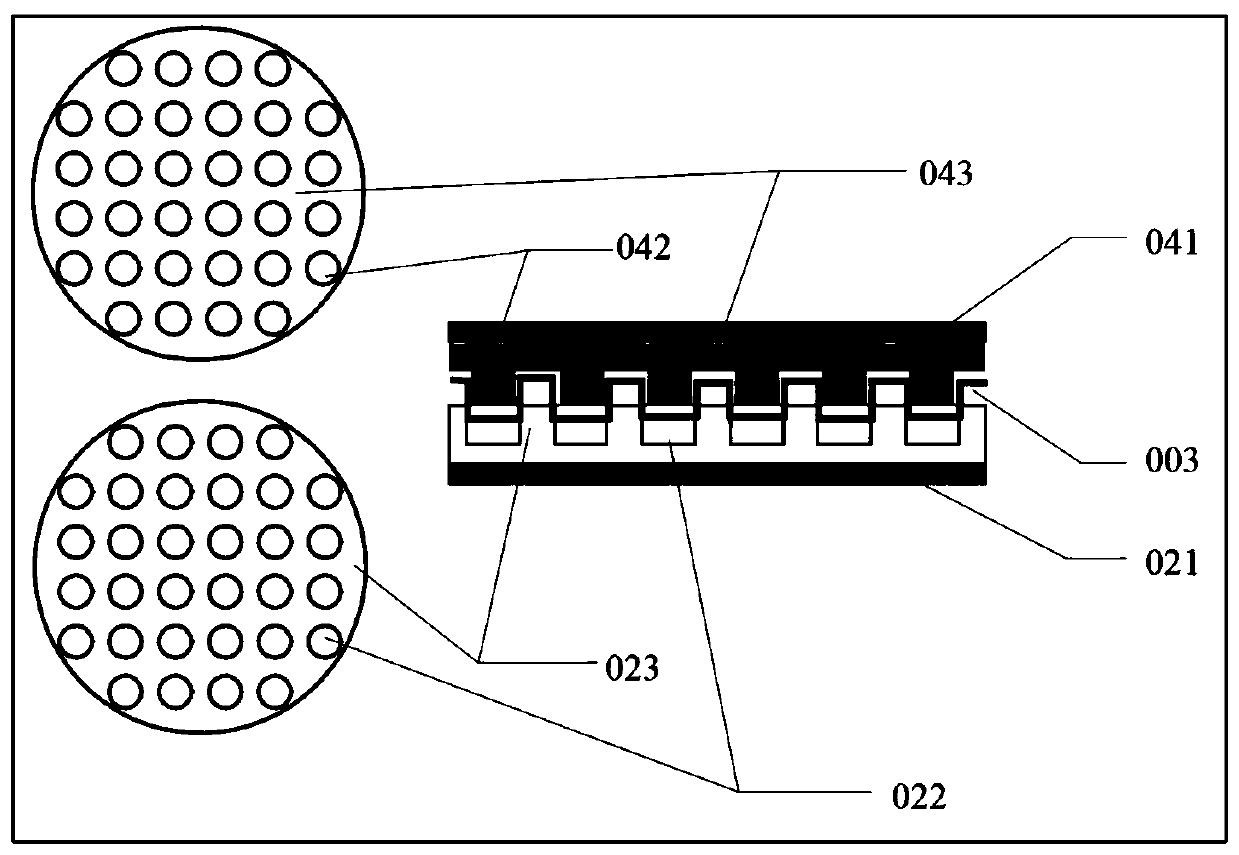

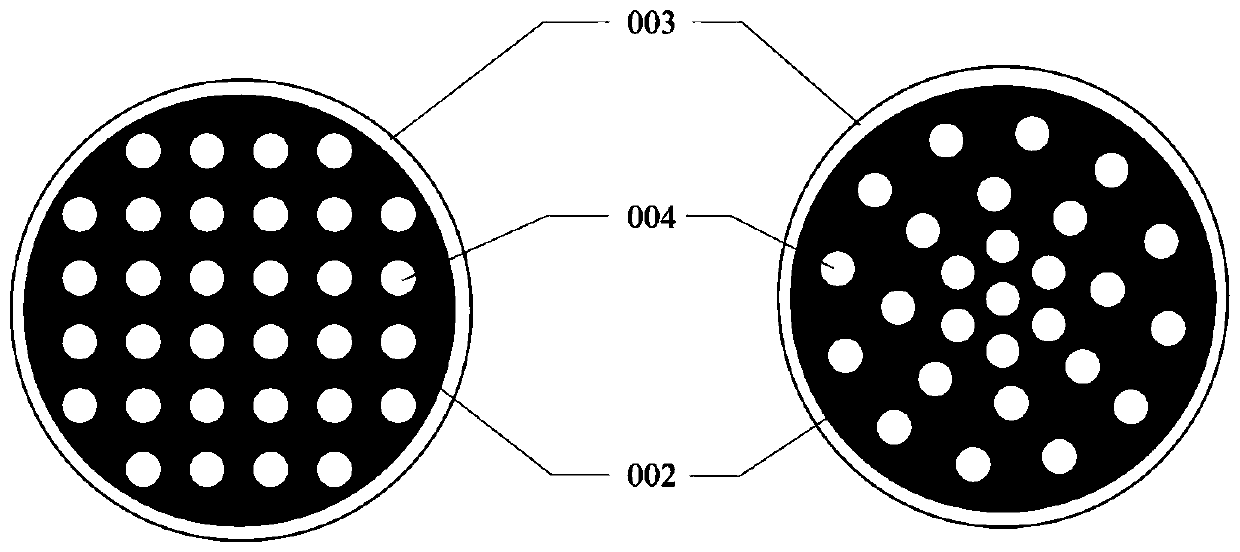

[0048] A CR1220 honeycomb lithium-ion button battery arranged in a rectangular array, characterized in that the honeycomb holes of the positive electrode sheet and the corresponding negative electrode sheet bosses are arranged in a rectangular array, and the bosses of the negative electrode sheet are embedded in the honeycomb holes of the positive electrode sheet form a tight connection. The preparation and assembly steps of the described honeycomb lithium-ion button cell are as follows:

[0049] (1) Positive plate preparation:

[0050]The positive electrode sheet uses NCM523 ternary material as the active material, and the active material, conductive agent, binder and solvent are stirred at high speed to prepare a slurry. The positive electrode slurry is coated on the aluminum foil current collector, and the electrode sheet is baked and dried for honeycomb manufacturing. ...

Embodiment 2

[0065] A kind of honeycomb lithium-ion button battery arranged in a CR2032 annular array and its assembly:

[0066] A honeycomb lithium-ion button battery arranged in a CR2032 annular array is characterized in that the honeycomb holes of the positive electrode sheet and the corresponding negative electrode sheet bosses are arranged in a circular array, and the bosses of the negative electrode sheet are embedded in the honeycomb holes of the positive electrode sheet to form Tight connection. The preparation and assembly steps of the honeycomb lithium-ion button cell are as follows:

[0067] (1) Positive plate preparation:

[0068] The positive electrode sheet uses NCM622 ternary material as the active material, and the active material, conductive agent, binder and solvent are stirred at high speed to prepare a slurry. The positive electrode slurry is coated on the aluminum foil current collector, and the electrode sheet is baked and dried for honeycomb manufacturing. Hole and...

Embodiment 3

[0083] A honeycomb lithium-ion button battery arranged in a CR2016 rectangular array and its assembly:

[0084] A honeycomb lithium-ion button battery arranged in a CR2016 rectangular array, characterized in that the positive electrode sheet is a honeycomb porous structure, the honeycomb holes are arranged in a rectangular array, the negative electrode sheet is a micron-sized cylindrical monomer, and the negative electrode slurry is coated on the ceramic honeycomb In the mold, after drying, the mold is released to obtain a micron-sized cylindrical monomer. The outer layer of a single negative cylinder monomer is covered with a diaphragm, and the upper layer is stacked with foamed nickel gaskets, which are embedded in the honeycomb holes. The diameter is 80-90% of the honeycomb holes, and the height is 75-90% of the hole depth. The preparation and assembly steps of the honeycomb lithium-ion button cell are as follows:

[0085] (1) Positive plate preparation:

[0086] The posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com