Environmentally-friendly aqueous battery and preparation method thereof

An environmentally friendly, water-based electrolyte technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high demagnesization potential, low voltage platform, difficult preparation, etc., and achieve high specific capacity and high charge-discharge capacity. , the effect of good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The exemplary preparation method of the above-mentioned exemplary environment-friendly aqueous battery of the present invention comprises the following steps:

[0056] 1. Preparation of positive electrode sheet

[0057] Spinel type Mn 3 o 4 Commercially available materials can be directly used, coated and nano-sized; materials prepared by hydrothermal synthesis can also be used.

[0058] The positive electrode material is mixed and ground with conductive carbon black and a binder (polyvinylidene fluoride (PVDF) or polytetrafluoroethylene (PTFE)), and the mixture is ground after adding a solvent. The active material is uniformly coated on graphite paper, stainless steel mesh or stainless steel sheet, and dried to obtain a positive electrode sheet. Wherein the particle size of the positive electrode material is 10nm-10μm, the mass ratio of the positive electrode material particles, conductive carbon black and binder is 60-80:30-10:20-10; the active material load in the...

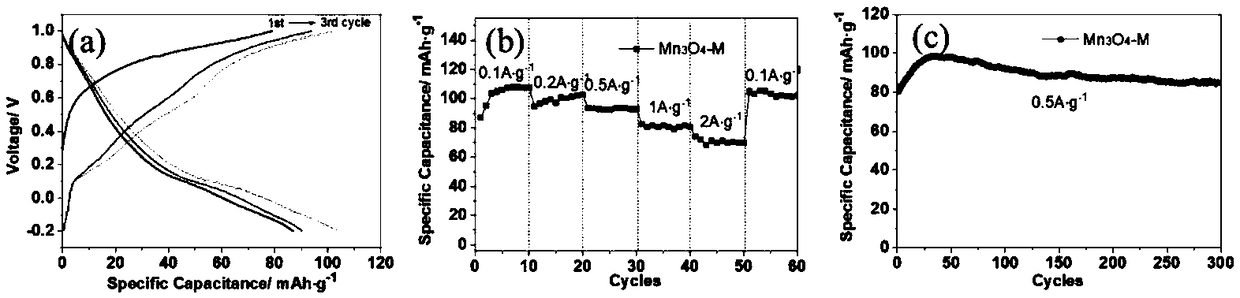

Embodiment 1

[0072] Will commercially available Mn 3 o 4 (Mn 3 o 4 -C) (purchased from Wokai Chemical Industry) was put into a horizontal ball mill (the diameter of the grinding medium was about 0.5mm), and was ground in an ethanol solution at a speed of 2500r / min for 2 hours to obtain the ground Mn 3 o 4 (Mn 3 o 4 -M). Activated carbon was purchased from YiHuan Carbon (YEC-8A) and used without further purification.

[0073]Mix and grind the positive and negative active materials with conductive carbon black and binder (polyvinylidene fluoride) for 10 minutes respectively, and the mass ratio of the three substances is 8:1:1; after adding a few drops of N-methylpyrrolidone Grind for 15 minutes, evenly coat the positive and negative active materials on graphite paper, and dry at 80°C for 2 hours; finally, take out the dried positive and negative electrodes and cut them into multiple discs. The accuracy of use is after the decimal point The five-digit electronic balance accurately wei...

Embodiment 2

[0077] Preparation method of cathode material: Mn 3 o 4 It was purchased from Gray Company (Hunan, China) and used as received. mn 3 o 4 Mix with conductive carbon black at a speed of 500 r / min for 120 min in a planetary ball mill (ball mill diameter is about 5 mm) at a mass ratio of 8:1.

[0078] Preparation method of negative electrode material: firstly, prepare 0.01mol citric acid solution. Add sodium carbonate, tetrabutyl titanate and ammonium dihydrogen phosphate with a molar ratio of 1:4:6 to the citric acid solution, and ensure that the molar ratio of sodium:citric acid is 1:1. 100 mg of graphene oxide and 0.2 g of cetyltrimethylammonium bromide (CTAB) were added to the above solution, and vigorous stirring was continued for several hours. Then, the solution was dried at 80 °C to obtain the precursor. The precursor was calcined in an Ar gas atmosphere, kept at 350°C for 1 hour, and then heated to 800°C for 1 hour to obtain NaTi 2 (PO 4 ) 3 -Carbon composites (N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com