Preparation method and application of silver vanadate/vanadium oxide one-dimensional composite nano-electrode material

A nano-electrode, vanadium oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficulty in obtaining nano-sized materials, low material conductivity, poor cycle stability, etc., and achieve high specific capacity and low reaction temperature , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a silver vanadate / vanadium oxide one-dimensional composite nanostructured lithium battery positive electrode material, comprising the following sequential steps:

[0033] (1) 0.18g vanadium pentoxide is dissolved in the hydrogen peroxide that mass fraction is 30%, adds 20mL deionized water and obtains transparent peroxovanadic acid solution;

[0034] (2) 0.05g silver nitrate is dissolved in 40mL deionized water;

[0035] (3) Pour the silver nitrate solution into the perovanadic acid solution, mix and fully stir, pour it into a 100mL polytetrafluoroethylene-lined autoclave, and keep it warm at 120°C for about 24h;

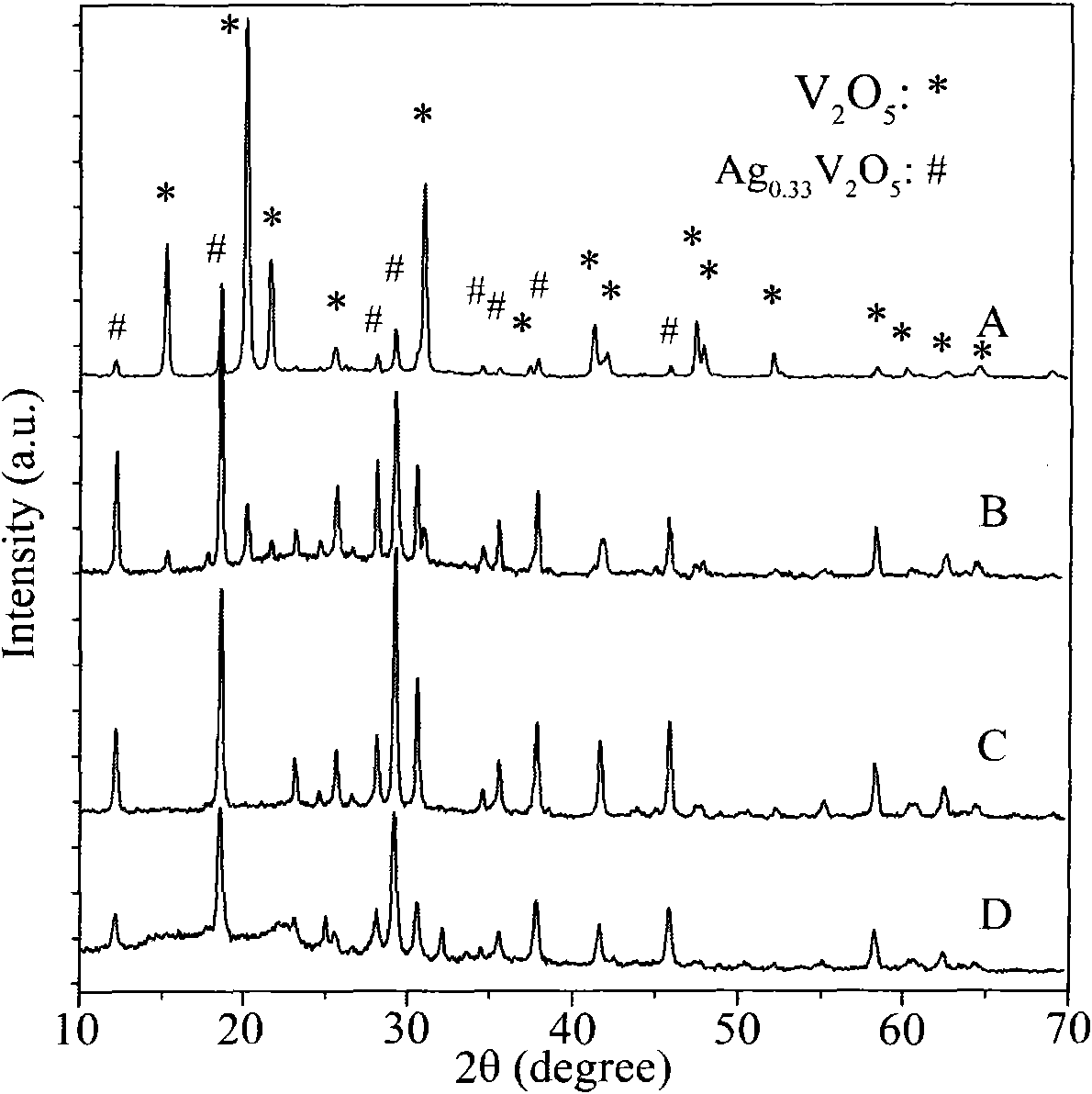

[0036] (4) After the reaction product is centrifuged, washed and dried, Ag 0.33 V 2 o5 / V 2 o 5 One-dimensional nanoribbons. like figure 1 (D), its XRD pattern shows that the diffraction peak is wider, the crystallinity of the product is not very high, and the diffraction peak can be attributed to silver vanadate Ag 0.33 V 2 o ...

Embodiment 2

[0038] A preparation method of a silver vanadate / vanadium oxide one-dimensional composite nanostructured lithium battery positive electrode material, comprising the following sequential steps:

[0039] (1) 0.243g sodium metavanadate is dissolved in 30% hydrogen peroxide, and 20mL deionized water is added to obtain a transparent perovanadic acid solution;

[0040] (2) Disperse 0.077g silver oxide into 40mL deionized water;

[0041] (3) Pour the silver salt solution into the perovanadic acid solution, mix and fully stir, pour it into a 100mL polytetrafluoroethylene-lined autoclave, and keep it warm at 200°C for about 16h;

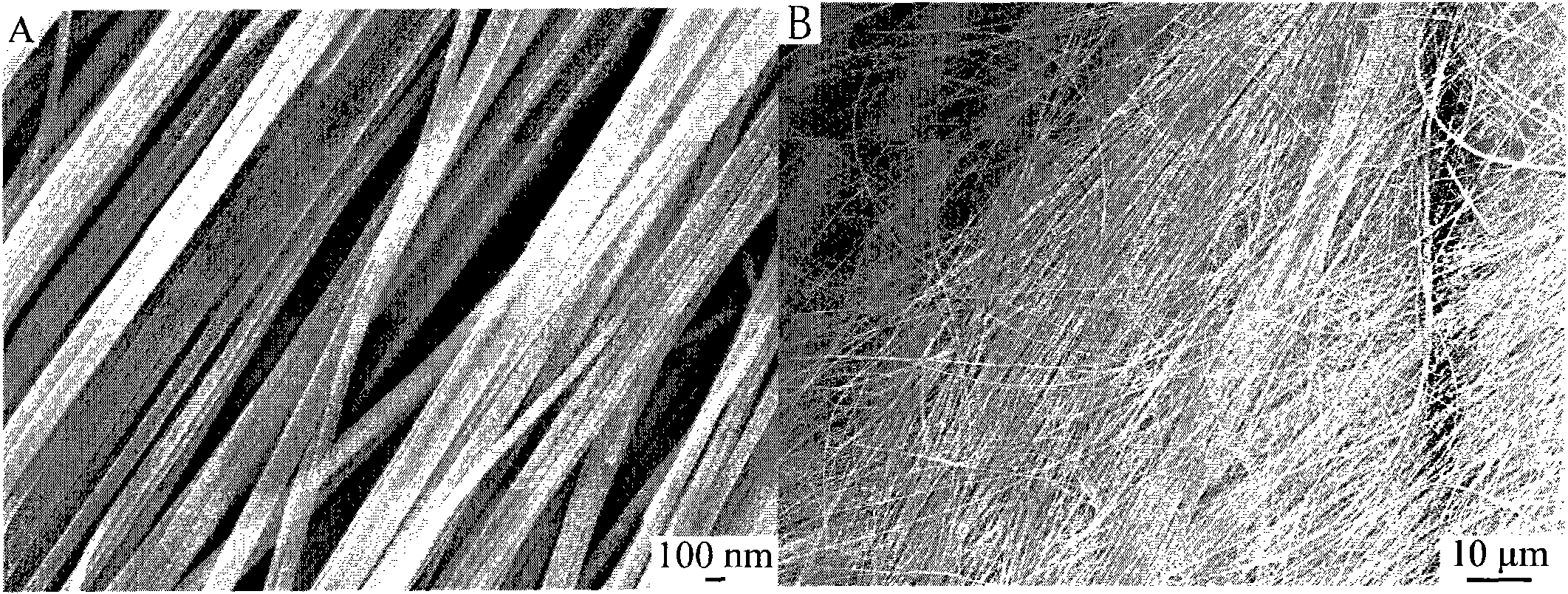

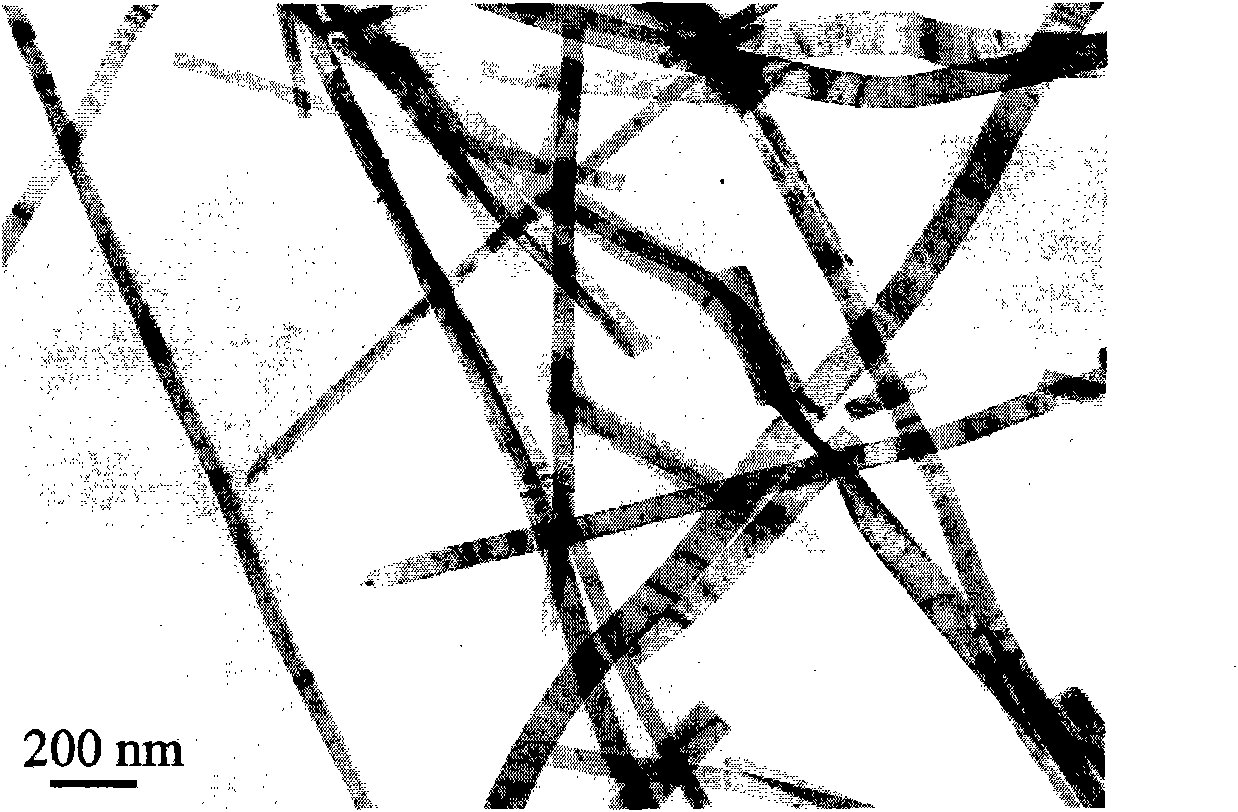

[0042] (4) After the reaction product is centrifuged, washed and dried, Ag 0.33 V 2 o 5 / V 2 o 5 One-dimensional nanoribbons. From the SEM photos ( figure 2 ) It can be seen that the surface of the synthesized one-dimensional vanadium oxide-silver vanadate composite nanostructure is very smooth, the length of the nanobelt is about a dozen microns, the...

Embodiment 3

[0044] A preparation method of a silver vanadate / vanadium oxide one-dimensional composite nanostructured lithium battery positive electrode material, comprising the following sequential steps:

[0045] (1) 0.234g ammonium metavanadate is dissolved in hydrogen peroxide, and 20mL deionized water is added to obtain a transparent perovanadic acid solution;

[0046] (2) Disperse 0.055g of silver acetate in 40mL of deionized water;

[0047] (3) Pour the silver salt solution into the perovanadic acid solution, mix and fully stir, pour it into a 100mL polytetrafluoroethylene-lined autoclave, and keep it warm at 160°C for about 20h;

[0048] (4) After the reaction product is centrifuged, washed and dried, Ag 0.33 V 2 o 5 / V 2 o 5 One-dimensional nanoribbons. Electrochemical tests show that the silver vanadate / vanadium oxide one-dimensional composite nanostructure synthesized by this method has high discharge specific capacity and good cycle stability at different current densitie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com