OMC/sponge Pb composite structure material lead plaster and preparing method and application thereof

A composite structure, sponge technology, applied in the field of electrochemistry, can solve the problems of short cycle life, uneven dispersion of carbon materials, slow research progress, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

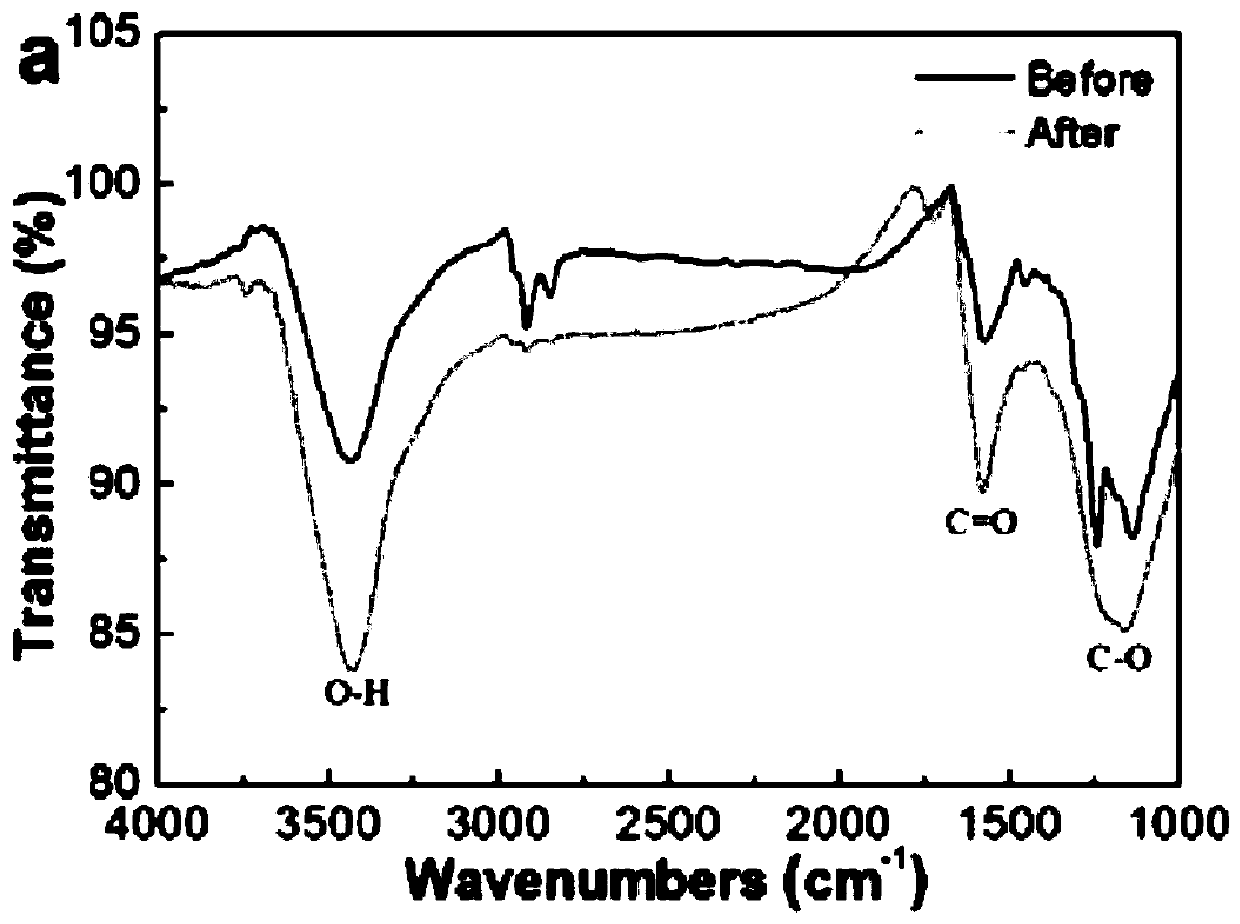

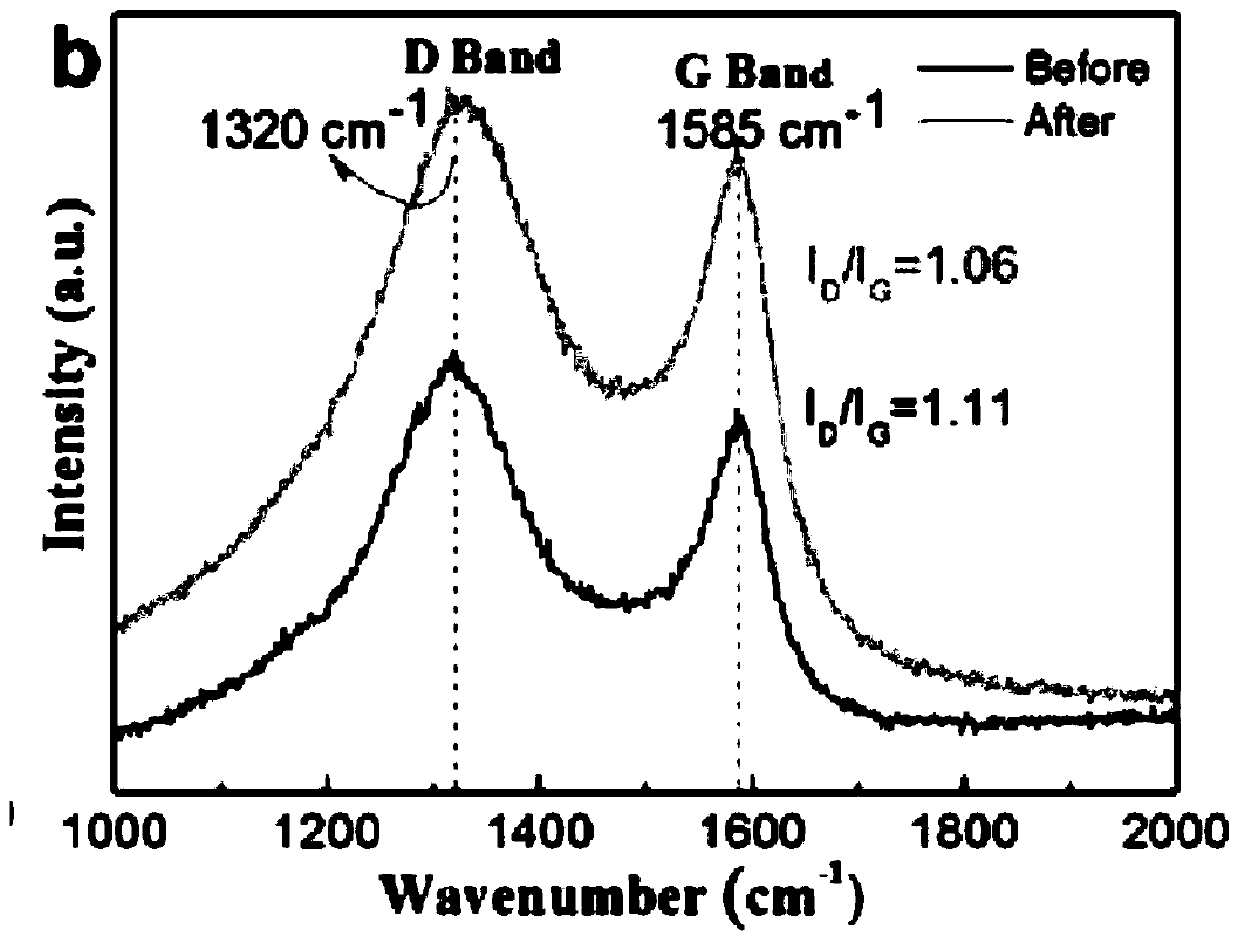

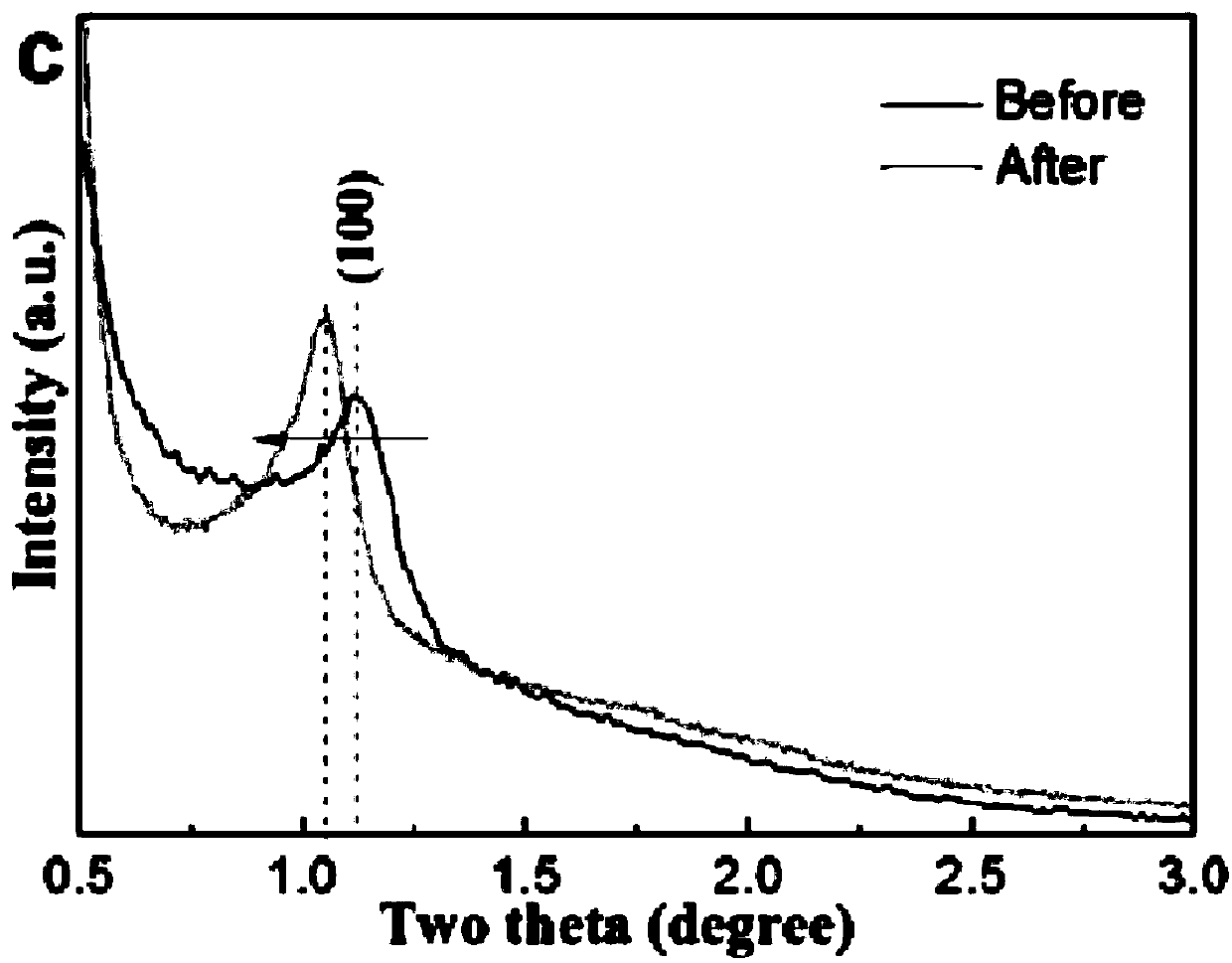

[0049] Add 50g of OMC to 2000ml of 10% H 2 o 2 Solution, accompanied by stirring, reacted for 2h, and the reaction temperature was 60°C. After the reaction, the reactants were cooled to room temperature, the supernatant solution was removed, the obtained suspension was centrifuged 3 times, washed and filtered with deionized water repeatedly until neutral, and dried in a drying oven at 60°C to constant weight; A hydrophilic ordered mesoporous carbon is obtained.

[0050] The characterization methods of OMC are as follows: (1) Burier transform infrared spectroscopy (FT-IR, Nicolet6700) to characterize the functional groups of the sample; (2) laser Raman spectrometer (Raman, Dilor LABRAM-1B microscope) to characterize the structure of the sample (3) X-ray diffractometer (XRD, Philips XPert pro MPD) characterizes the crystal phase composition of the sample; (4) Scanning electron microscope (SEM, JSM-7500F) characterizes the surface morphology of the sample; (5) Transmission elec...

Embodiment 2

[0080] Weigh 50 g of the hydrophilic OMC prepared in Example 1 and add it into 100 kg of deionized water, and stir for 30 min at a room temperature of 25° C. to obtain a uniform OMC dispersion.

[0081] The OMC dispersion is added into a paste mixer and mixed with 1000kg of lead powder to obtain a mixture. In order to realize the uniform mixing of OMC and lead powder, and to ensure the stability of negative OMC / sponge Pb composite lead paste paste, the binding ability of the plate and lead paste, add bonding agent during the mixing and stirring process of OMC dispersion liquid and lead powder Substance short fiber, its addition amount is 0.015% of the overall mass of the mixture.

[0082] In the mixture of mixed OMC and lead powder, add 100kg of sulfuric acid with a density of 1.325g / ml and stir for 20min, the reaction temperature is controlled at 65°C, and the obtained OMC / sponge Pb composite material lead paste has an apparent density of 4.28g / cm 3 .

[0083] The surface...

Embodiment 3

[0104] Negative plate prepared by machine coating: the apparent density prepared in Example 2 is 4.28g / cm 3 The OMC / sponge Pb composite material lead paste is used to prepare the OMC-based composite negative electrode, or in other words, the OMC-based composite negative electrode is the OMC / sponge Pb composite electrode. Among them, the OMC / sponge Pb composite material lead paste is all coated on the negative grid. The size of the negative grid is: 68mm×44mm×1.7mm, and it is made of lead-calcium-tin alloy with a calcium content of 0.09% and a tin content of 0.3%. . Certainly, the lug portion of the negative electrode grid does not need to be coated. The negative electrode grid coated with the sponge Pb composite material lead paste is continuously cured for 24 hours at 60°C and humidity 85-95%; then continuously dried for 24 hours at 60°C and humidity less than 50% to make the negative electrode The plate is the OMC-based composite negative electrode. After the composite el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com