Negative electrode material of lithium-ion battery, preparation method thereof, negative electrode and lithium-ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, negative electrodes, etc., can solve problems such as poor conductivity, achieve the effects of enhancing conductivity, increasing charge transfer rate, and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a kind of preparation method of lithium-ion battery negative electrode material as above, comprises the steps:

[0039] Mix and dissolve silicon monoxide particles, graphite particles, binders and surfactants in a solvent to form a suspension;

[0040] After the suspension is spray-dried, it is calcined to obtain the lithium-ion battery negative electrode material.

[0041] According to a specific embodiment of the present invention, the binder is a carbon-containing soluble organic compound, and the surfactant is a long-chain organic compound. Wherein, the binder accounts for 1-20% by weight of the whole solid particles (silicon oxide particles, graphite particles, binder and surfactant). The surfactant accounts for 1-5% by weight of the whole solid particle.

[0042] According to a specific embodiment of the present invention, the binder includes at least one of monosaccharide, oligosaccharide or polysaccharide, and the surfactant...

Embodiment 1

[0063] Mix 3-(methacryloyloxy)propyltrimethoxysilane (MPS) and silicon monoxide (SiO) and dissolve in ethanol water solvent, wherein the mass percentage of water in the ethanol water mixed solvent is 20%. After mixing a suspension was formed which had a pH of 4.5. The suspension was dispersed by ultrasonic for 30 minutes, then heated to 70-80° C. for 6-8 hours, and stirred while reacting. After the reaction was completed, the reaction solution was centrifuged, and the precipitate was vacuum-dried to obtain SiO grafted with PNIPAAM.

Embodiment 2

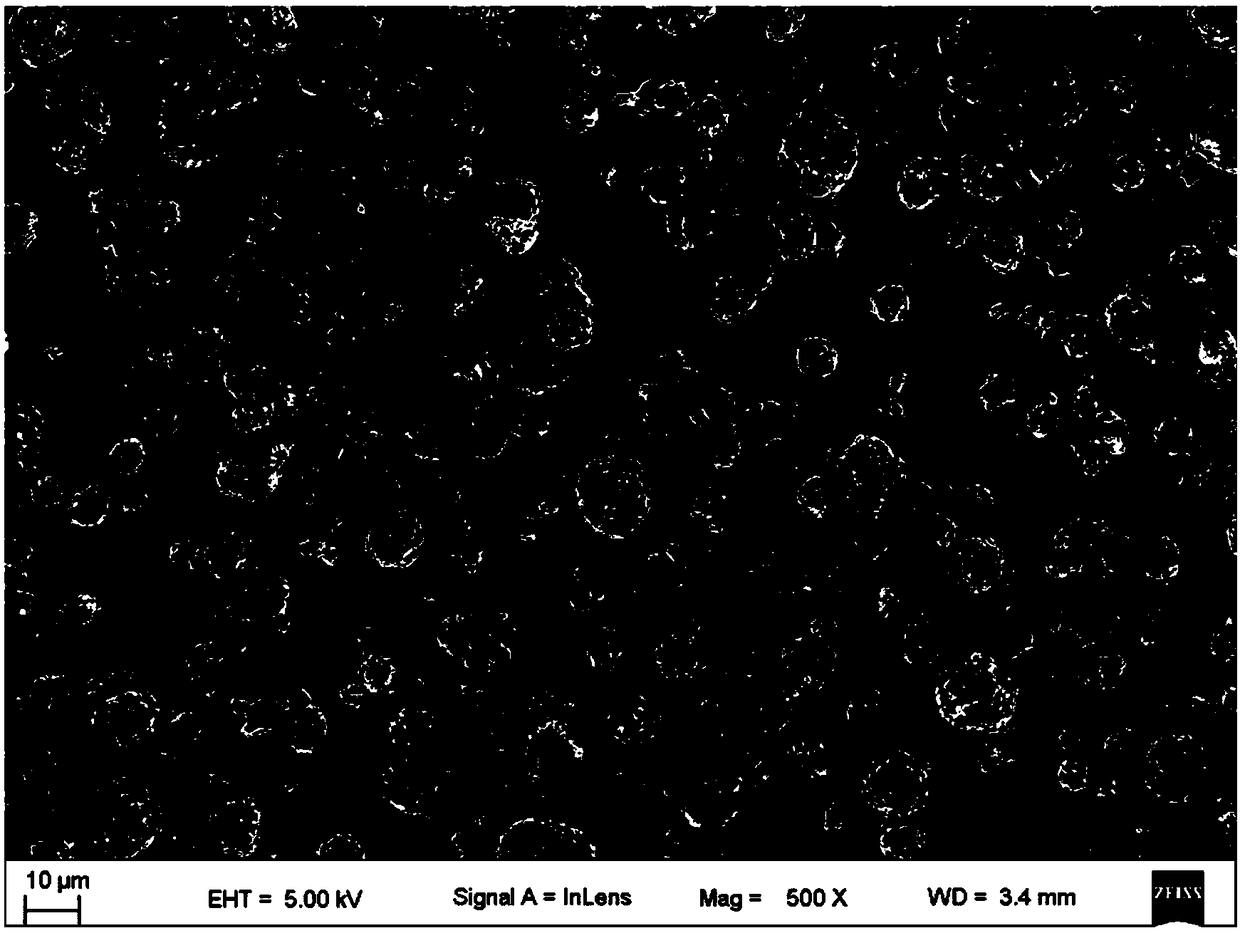

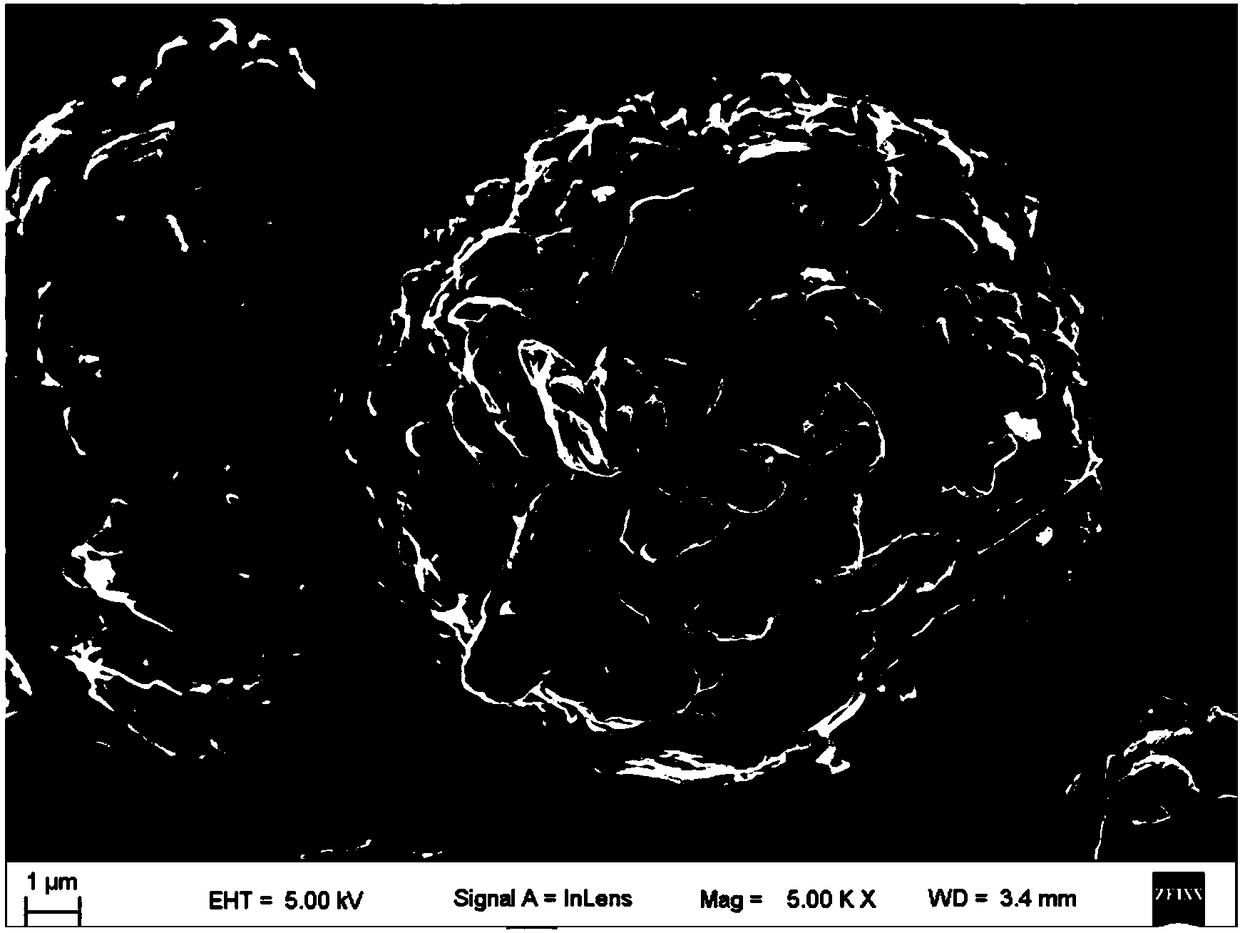

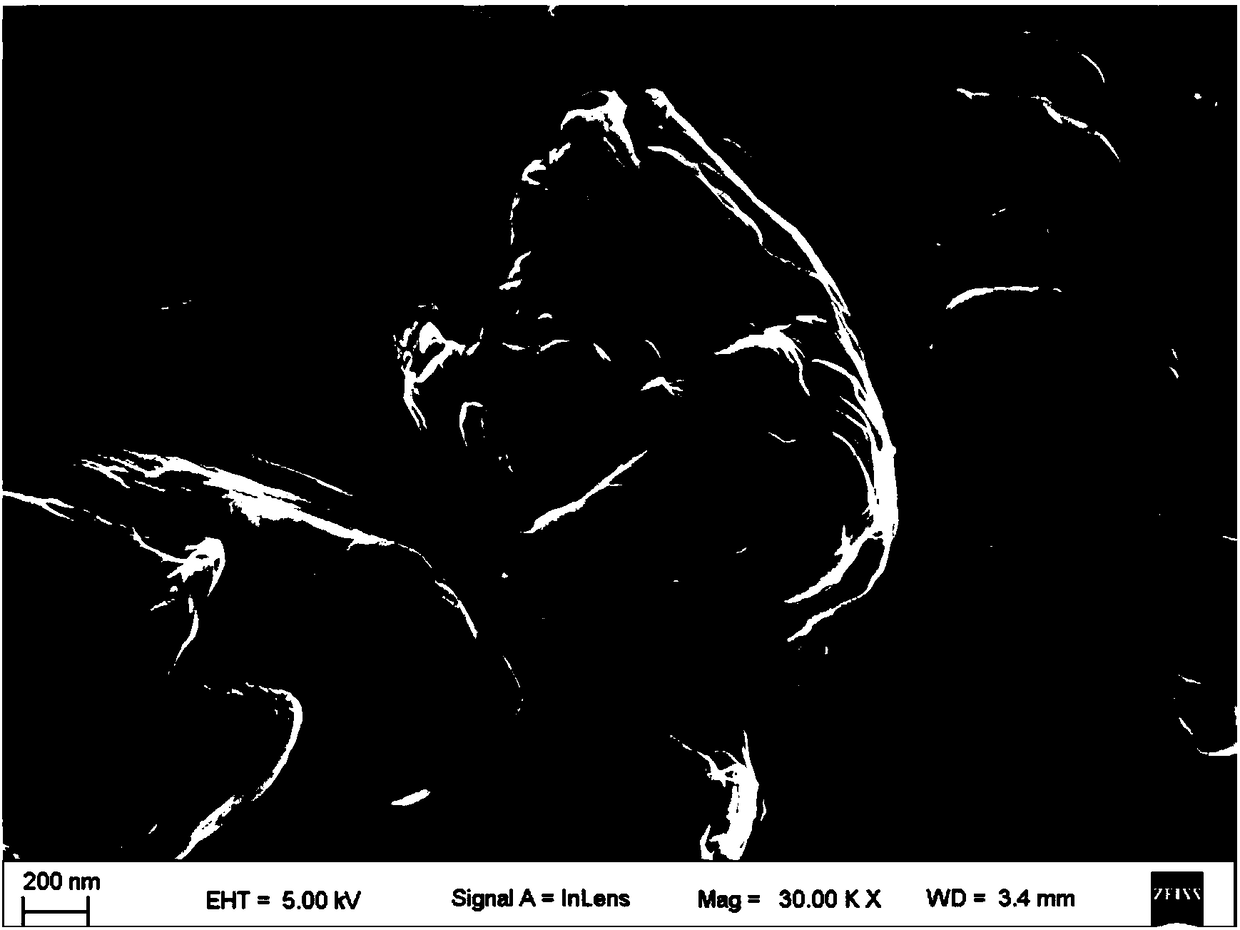

[0065] 100 grams of SiO with an average diameter of 1 micron, 100 grams of sucrose, 1800 grams of graphite with an average particle diameter of 5 microns and 3 grams of sodium dodecylbenzenesulfonate (SDBS) were added to 7 kg of water and dispersed by mechanical stirring. The mixture is spray-dried at 155-170° C. to obtain a pomegranate structure negative electrode material. These anode materials were then calcined in a furnace at 800-850° C. for 2-4 hours under an argon atmosphere to produce particles with an average diameter of about 15 μm. The particle BET specific surface area is 2.9348m 2 / g.

[0066] As shown in Figure 1 and Figure 2, SEM and EDS were used to characterize the negative electrode material. The scanning electron microscope photo in Figure 1 shows that SiO and graphite particles have aggregated into a composite structure. The attached EDS image of Figure 2 shows that the structure is uniformly aggregated by multiple graphite particles and SiO particles.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com