Preparation process of composite fiber electrode material for sodium-ion battery

A sodium-ion battery and composite fiber technology, applied in battery electrodes, non-aqueous electrolyte storage batteries, circuits, etc., can solve the problems of low volumetric energy density and low active material content, and achieve simplified preparation process, low cost, and improved cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A preparation process for a composite fiber electrode material for a sodium ion battery, comprising the steps of:

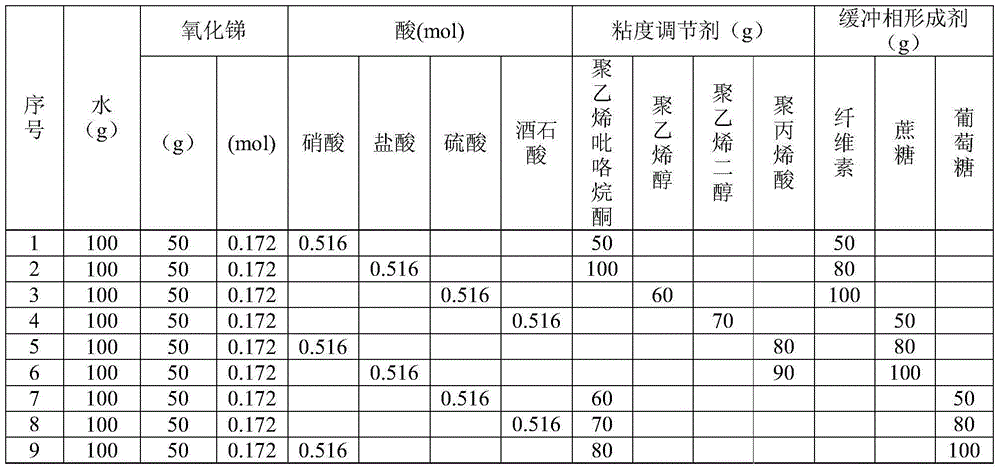

[0022] The first step: prepare the precursor solution, add 50% antimony oxide (Sb 2 o 3 ), then add any acid of nitric acid, hydrochloric acid, sulfuric acid and tartaric acid with a molar mass of 300% of antimony oxide to dissolve the antimony oxide to obtain a solution containing antimony, and then add 50-100% deionized water quality to the solution % viscosity regulator and water mass 50-100% buffer phase forming agent to obtain a precursor solution. Wherein, the viscosity regulator is one of polyvinylpyrrolidone, polyvinyl alcohol, polyethylene glycol, and polyacrylic acid; the buffer phase forming agent is one of cellulose, sucrose, and glucose; Table 1 lists the number as 1 The formula composition of 9 embodiments of -9.

[0023] The formula of table 1 raw material

[0024]

[0025] Note: The addition amount of nitric acid, hydrochloric acid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com