Modified ferric fluoride nano-composite anode material and preparing method and application thereof

A positive electrode material and nanocomposite technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of poor polarization rate performance and cycle performance, small specific capacity of lithium-ion batteries, ion Bond-to-bond energy bandgap width and other issues to achieve the effect of improving rate characteristics and energy density, excellent rate characteristics and cycle performance, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

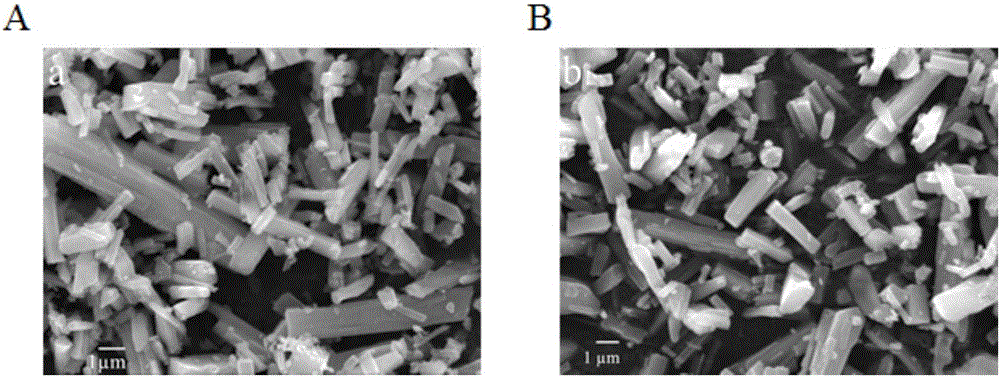

[0042] Example 1 Preparation of modified ferric fluoride nanocomposite cathode material

[0043] Prepare 0.15mol / L Fe(NO 3 ) 3 9H 2 O ethanol solution; prepare 0.45mol / L NH at a molar ratio of iron ion to fluoride ion of 1:3 4 The ethanol solution of F; the prepared Fe(NO 3 ) 3 9H 2 O ethanol solution and NH 4 Mix the F ethanol solution at 25°C and 101.325Kpa, then add 0.05mol CrCl 3 ·6H 2 O, mix and stir at a constant speed for 8 hours, then centrifuge at 6000r / min for 20 minutes, discard the supernatant and wash the centrifuged sediment with absolute ethanol for 2 to 3 times; dry the washed sediment in a vacuum oven at 80°C for 5 hours, then Carry out heat treatment and sintering in a tube-type atmosphere furnace filled with Ar atmosphere, heat up at a rate of 5°C / min, react at a constant temperature of 300°C for 15 hours, then cool down at a rate of 10°C / min, and then pulverize the sintered material after cooling down to room temperature , sieve to get doped Cr 3+...

Embodiment 2

[0044] Example 2 Preparation of modified ferric fluoride nanocomposite cathode material

[0045] Prepare 0.2mol / L Fe(NO 3 ) 3 9H 2 O ethanol solution; prepare 0.64mol / L NH at a molar ratio of iron ion to fluoride ion of 1:3.2 4 The ethanol solution of F; the prepared Fe(NO 3 ) 3 9H 2 O in ethanol and NH 4 Mix the ethanol solution of F at 25°C and 101.325Kpa, then add 0.1mol CrCl 3 ·6H 2 O, mix and stir at a constant speed for 10 hours, then centrifuge at 6000r / min for 10 minutes, discard the supernatant and wash the centrifuged precipitate with absolute ethanol for 2 to 3 times; dry the washed precipitate in a vacuum oven at 70°C for 8 hours, then Carry out heat treatment and sintering in a tube-type atmosphere furnace filled with Ar atmosphere, heat up at a rate of 5°C / min, react at a constant temperature of 350°C for 13 hours, cool down at a rate of 10°C / min, and cool down to room temperature, then pulverize the sintered material, Sieve to get doped Cr 3+ The ferri...

Embodiment 3

[0046] Example 3 Preparation of modified ferric fluoride nanocomposite cathode material

[0047] Prepare 0.18mol / L Fe(NO 3 ) 3 9H 2 Ethanol solution of O; prepare 0.648mol / L NH according to the molar ratio of iron ion and fluoride ion as 1:3.6 4 The ethanol solution of F; the prepared Fe(NO 3 ) 3 9H 2 O in ethanol and NH 4 Mix the ethanol solution of F at 25°C and 101.325Kpa, then add 0.2mol CrCl 3 ·6H 2 O, mix and react at a constant speed for 5 hours, then centrifuge at 6000r / min for 30 minutes, discard the supernatant and wash the centrifuged sediment with absolute ethanol 2-3 times; dry the washed sediment in a vacuum oven at 80°C for 6 hours, Then carry out heat treatment and sintering in a tube-type atmosphere furnace filled with Ar atmosphere, heat up at a rate of 10°C / min, react at a constant temperature of 400°C for 13 hours, cool down at a rate of 10°C / min, and then pulverize the sintered material after falling to room temperature , sieve to get doped Cr 3+...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com