Graphene-coated lithium battery anode material and preparation method thereof

A graphene-coated, positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as inability to effectively suppress polysulfide compounds, material conductivity needs to be improved, and preparation methods are required to be high. Electrochemical properties, the effect of reducing fabrication cost, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

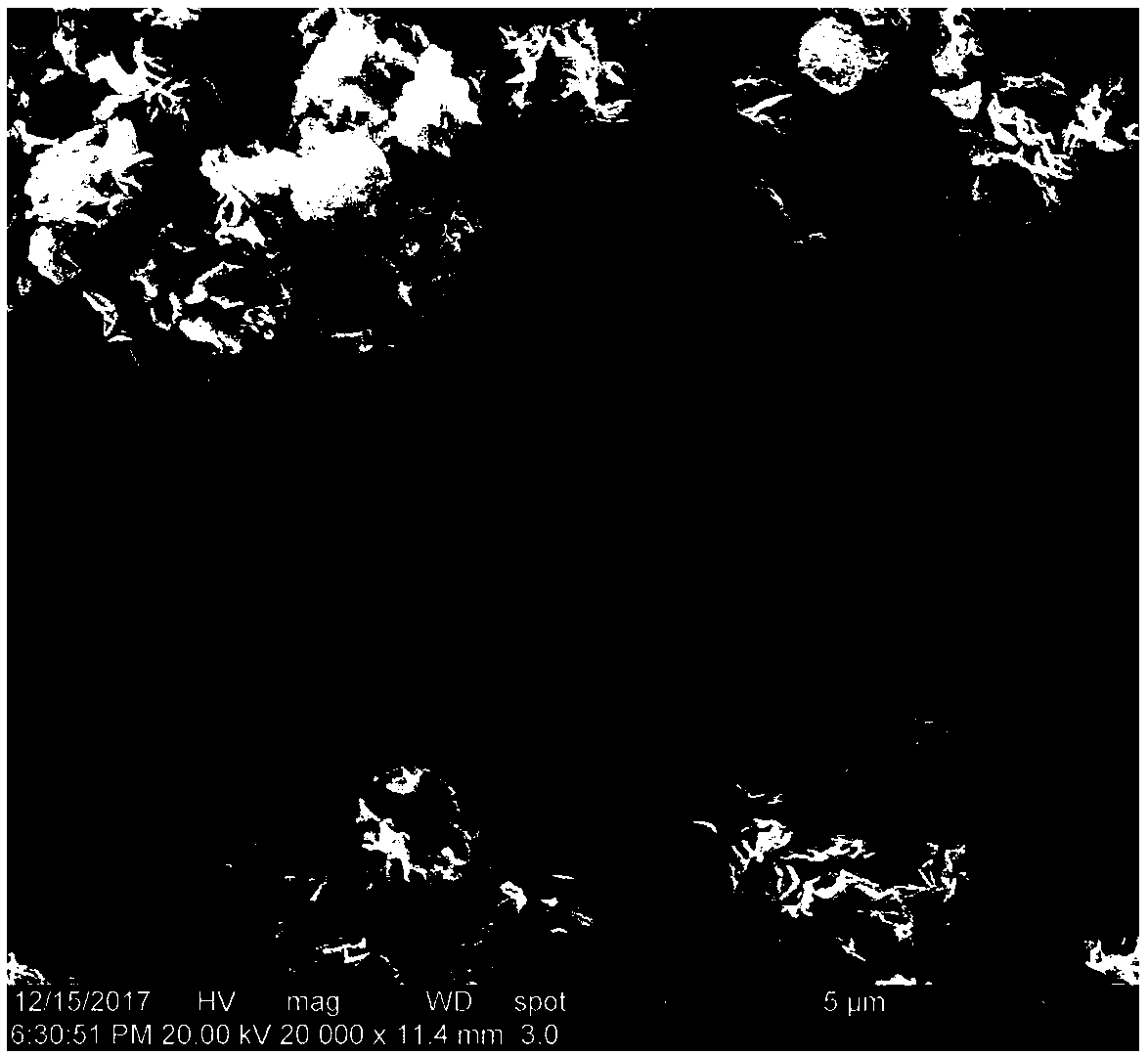

Image

Examples

Embodiment 1

[0031] A preparation method of a graphene-coated lithium battery cathode material, comprising the following steps:

[0032] (1) 0.3g cuprous chloride, 0.4g thiourea and 0.05g polyvinylpyrrolidone (PVP) are dissolved in the ethanol of 95% (v / v), make precursor solution, prepare precursor solution according to reaction kettle volume 60 The amount of % is added in the reactor;

[0033] (2) Add 10 mg of graphene oxide to the reaction kettle, stir for 20 minutes, and mix the precursor liquid and graphene oxide evenly;

[0034] (3) After sealing the reaction kettle, put it into a blast drying oven, heat it at 120°C for 5h, wash it with absolute ethanol three times, then wash it with deionized water three times, and dry it under vacuum at 60°C for 6h;

[0035] (4) After dissolving the product of step (3) with carbon disulfide, centrifuge three times with absolute ethanol, then centrifuge three times with deionized water, vacuum dry at 60°C for 6h, and sinter at 300°C for 20h in an a...

Embodiment 2

[0039] A preparation method of a graphene-coated lithium battery cathode material, comprising the following steps:

[0040] (1) Dissolve 0.5g cuprous chloride, 0.4g thiourea and 0.8g PVP in ethanol of 95% (v / v) to prepare a precursor solution, and add the precursor solution according to 80% of the volume of the reactor to react in the kettle

[0041] (2) Add 20 mg graphene oxide to the reaction kettle, stir for 60 min, and mix the precursor liquid and graphene oxide evenly;

[0042] (3) After sealing the reaction kettle, put it into a blast drying oven, heat it at 180°C for 24h, wash it with absolute ethanol three times, then wash it with deionized water three times, and vacuum dry it at 100°C for 12h;

[0043] (4) After dissolving the product of step (3) with carbon disulfide, centrifuge three times with absolute ethanol, then centrifuge three times with deionized water, vacuum dry at 100°C for 12h, and sinter at 800°C for 5h in an argon atmosphere to obtain Graphene-coated...

Embodiment 3

[0047]A preparation method of a graphene-coated lithium battery cathode material, comprising the following steps:

[0048] (1) Dissolve 0.5g cuprous chloride, 0.4g thiourea and 0.4g PVP in ethanol of 95% (v / v) to prepare a precursor solution, and add the precursor solution according to 70% of the volume of the reaction kettle to react in the kettle

[0049] (2) Add 100 mg of graphene oxide to the reaction kettle, stir for 30 minutes, and mix the precursor liquid and graphene oxide evenly;

[0050] (3) After sealing the reaction kettle, put it into a blast drying oven, heat it at 180°C for 12h, wash it with absolute ethanol three times, then wash it with deionized water three times, and vacuum dry it at 100°C for 10h;

[0051] (4) After dissolving the product of step (3) with carbon disulfide, centrifuge three times with absolute ethanol, then centrifuge three times with deionized water, vacuum dry at 100°C for 10h, and sinter at 500°C for 24h in an argon atmosphere to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com