PAMPSLi fiber based polymer electrolyte membrane preparation method utilizing electrospinning method

An electrospinning method and electrolyte membrane technology, which is applied in the field of preparation of polymer electrolytes for polymer lithium-ion batteries, can solve the problems of concentration polarization and low ion migration number, and achieve high liquid absorption rate and high ion conductivity rate, the effect of eliminating concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

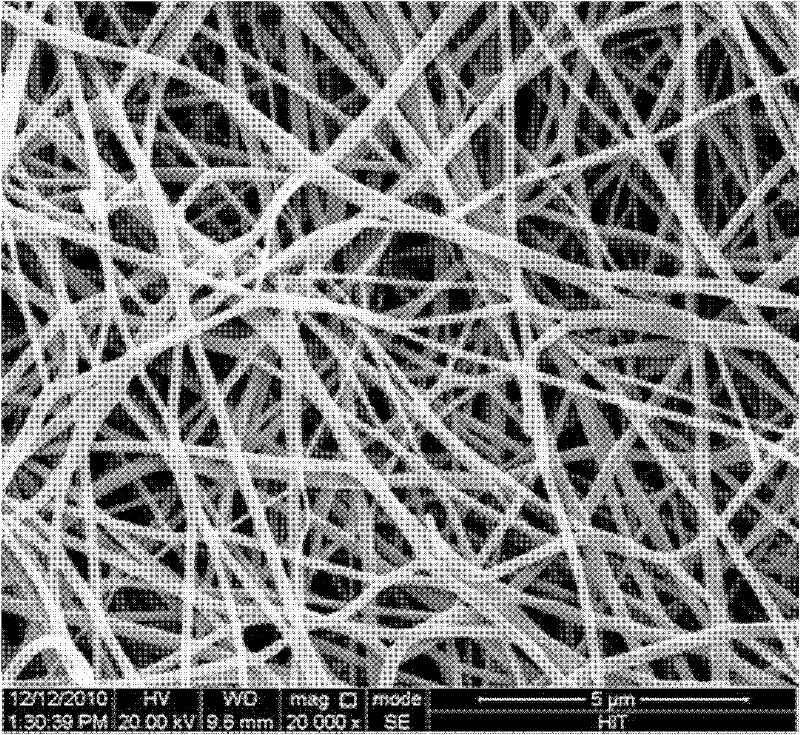

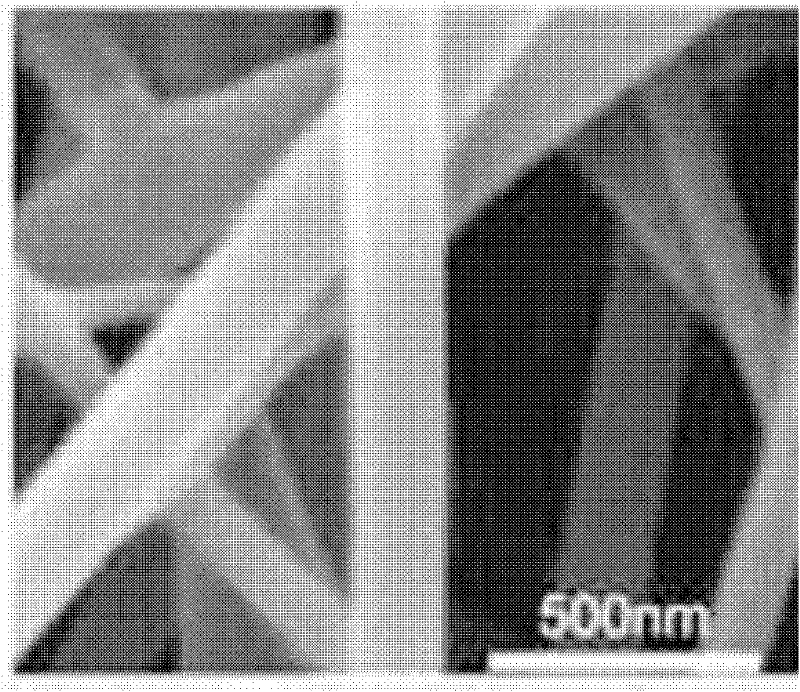

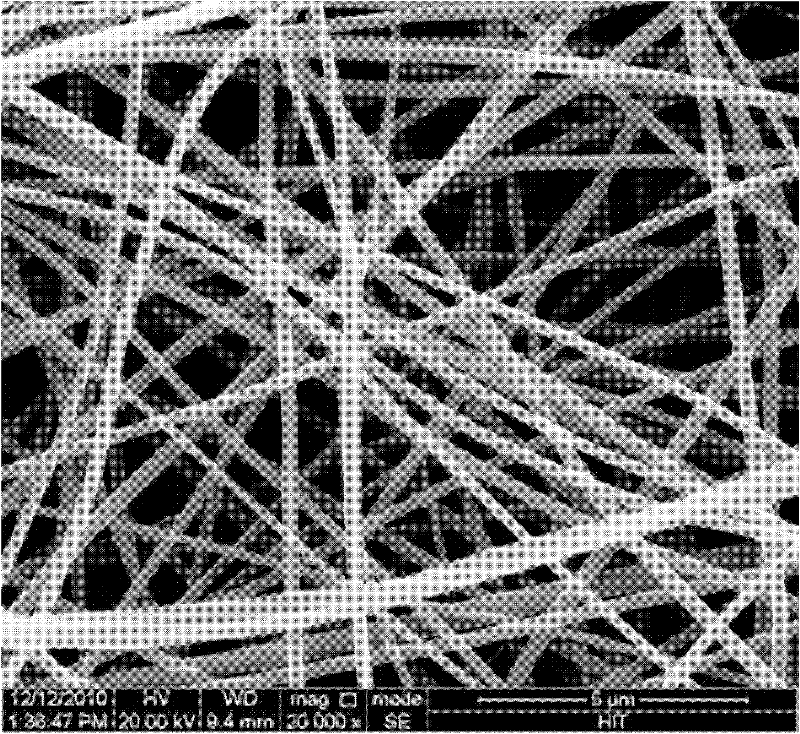

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the method for preparing PAMPSLi fiber-based polymer electrolyte membrane by electrospinning method in the present embodiment is carried out according to the following steps:

[0015] 1. Slowly add 2-acrylamide-2-methylpropanesulfonic acid (AMPS for short) into N, N-dimethylformamide (DMF for short, as a solvent) to make a concentration of 2.0mol / L 2- N,N-dimethylformamide solution of acrylamide-2-methylpropanesulfonic acid, then add azobisisobutyronitrile (abbreviated as AIBN, as initiator) to make the concentration of azobisisobutyronitrile equal to AMPS quality 1% of nitrogen gas for 30min (purpose to get rid of oxygen), then polymerized at 75°C for 10h to obtain the DMF solution of PAMPS;

[0016] Two, the DMF solution of PAMPS is diluted to PAMPS concentration with deionized water and is 40g / L, then slowly adds lithium carbonate (Li 2 CO 3 ) (lithium ions replace the hydrogen ions of the sulfonate group), lithium carbonate and 2-acrylamid...

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the electrospinning method described in step 3 uses a syringe pump to control the flow rate of the spinning solution, and extrudes the spinning solution from a stainless steel needle. The stainless steel needle is connected to the positive pole of the high-voltage power supply, the negative pole of the power supply is connected to the receiving plate, the distance between the fixed needle plates is 20cm, and the spinning voltage is 19kV. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the solvent described in step 3 is formed by mixing deionized water and ethanol at a mass ratio of 1:1. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com